Product Description

You can choose the 1 type that you need form these product introction.

If you have any question,please contact me.

HangZhou CHINAMFG Machinery Co.,ltd is a company specialized in research, manufacture and service of speed gearbox. Ever since establishment, we have been persisting in technical innovation, advancing the techonology to our products while maintaining our strict quality controls. It is the reason that our products branding ”Xihu (West Lake) Dis.n” have enjoyed such successful global sales.

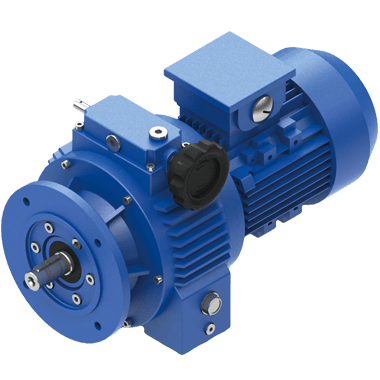

At present, our company mainly supplies 5 series products as RV worm gearbox, UDL series speed variator,PC series helical gear unit,G3 helical geared motor and SRC helical gearbox. The products are widely applied in the mechanical equipment field such as food and beverage,cement,package,chemical and dyeing, rubber and plastic, CNC machine tool,etc.

Our products have been processed ISO 9001 Quality System Certification and exported to Italy,Spain,Britain,Poland,Turkey.The USA and other European countries,earn the good reputation with our outstanding quality and service.

Customers first,customers satisfaction, excellent after sale service and incessant innovation are our tenet and motto. We will go all out to provide all the customers with high quality and servic /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical and Horizontal |

| Samples: |

US$ 69.9/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can variator motors be used in both fixed and variable speed applications?

Yes, variator motors can be used in both fixed and variable speed applications. Here’s a detailed explanation:

Variator motors, also known as variable speed motors or adjustable speed motors, are designed to provide flexibility in adjusting the motor’s speed according to the specific requirements of the application. This versatility allows them to be used in a wide range of applications, whether the desired speed is fixed or variable.

Here are some key points to consider regarding the use of variator motors in fixed and variable speed applications:

- Fixed Speed Applications: In fixed speed applications, where a constant speed is required throughout the operation, variator motors can still be used effectively. The motor can be set at the desired fixed speed during installation or through the control system. The advantage of using variator motors in fixed speed applications is that they often offer high efficiency and reliable performance, which can contribute to energy savings and reduced maintenance needs.

- Variable Speed Applications: Variator motors are particularly well-suited for variable speed applications, where the speed requirements may change based on different operational conditions or process demands. These motors allow for precise control over the motor’s speed, enabling optimization of the application’s performance. By adjusting the speed according to the specific requirements, variator motors can improve energy efficiency, enhance process control, reduce wear and tear on mechanical components, and enable better synchronization with other system elements.

- Speed Adjustment Range: Variator motors offer a wide range of adjustable speeds, allowing them to accommodate both fixed and variable speed applications. The speed adjustment range can vary depending on the specific model and type of variator motor. Some motors may have a limited range, while others can provide a broad range of speeds, spanning from low RPMs to high RPMs. When selecting a variator motor for a specific application, it’s essential to consider the required speed range and ensure that the motor can operate within those speed limits.

- Control Options: Variator motors often come with various control options that allow for easy adjustment of the motor’s speed. These control options can include manual control through potentiometers or dials, digital control through interface panels or keypads, or even programmable control through communication protocols such as Modbus or Ethernet. These control options facilitate the use of variator motors in both fixed and variable speed applications, as they provide flexibility in setting and changing the desired speed.

- Application Versatility: Variator motors are versatile and find applications in various industries and sectors. They can be used in applications such as conveyors, pumps, fans, compressors, mixers, machine tools, HVAC systems, robotics, and more. This versatility demonstrates how variator motors can be utilized effectively in both fixed and variable speed applications across different industries.

Overall, the use of variator motors offers flexibility and adaptability to meet the speed requirements of different applications, whether fixed or variable. By selecting the appropriate motor model, determining the desired speed range, and utilizing the available control options, variator motors can provide efficient and reliable performance in a wide range of applications.

Can variator motors be used in conjunction with renewable energy sources?

Yes, variator motors can be used in conjunction with renewable energy sources. Here’s a detailed explanation:

Renewable energy sources, such as solar power, wind power, hydroelectric power, or biomass, are increasingly being adopted to reduce reliance on fossil fuels and decrease greenhouse gas emissions. Variator motors offer compatibility and advantages when used in conjunction with renewable energy sources:

- Variable Speed Operation: Variator motors are well-suited for variable speed operation, which aligns with the intermittent and fluctuating nature of renewable energy sources. For example, solar power generation is dependent on sunlight availability, and wind power generation depends on wind speed. By adjusting the motor speed to match the available energy input, variator motors can optimize the use of renewable energy and enhance overall system efficiency.

- Energy Harvesting: Variator motors can be utilized for energy harvesting applications in renewable energy systems. For instance, in wind turbines, variator motors can function as generators to harvest and convert mechanical energy from the wind into electrical energy. Similarly, in hydroelectric power systems, variator motors can be used as generators to convert the potential energy of flowing water into electricity. This energy harvesting capability makes variator motors a valuable component in renewable energy generation.

- Grid Integration: Variator motors can facilitate the integration of renewable energy systems with the electrical grid. They can provide power conditioning functions by controlling the voltage, frequency, and power factor of the generated renewable energy. This ensures the compatibility and stability of the power output from renewable sources, allowing seamless integration with the grid and enabling efficient utilization of the generated energy.

- Load Balancing and Energy Storage: Variator motors can contribute to load balancing and energy storage in renewable energy systems. During periods of excess energy generation, when the renewable energy source produces more power than required, variator motors can be used to store the excess energy in energy storage systems, such as batteries or flywheels. Later, when the renewable energy source produces less power than demanded, the stored energy can be released by the variator motors to balance the load and ensure a continuous and stable power supply.

- Efficiency Optimization: Variator motors enable efficiency optimization when combined with renewable energy sources. By adjusting the motor speed and torque based on the available renewable energy input, variator motors can operate in the most efficient range, maximizing energy conversion efficiency and minimizing energy losses. This optimization contributes to overall system efficiency and improved utilization of renewable energy resources.

The use of variator motors in conjunction with renewable energy sources offers benefits such as enhanced system efficiency, increased renewable energy utilization, and improved grid integration. However, it’s important to consider specific requirements, system compatibility, and the expertise of motor manufacturers and renewable energy professionals when implementing such systems. Consulting with experts in the field can help ensure the optimal integration and performance of variator motors in renewable energy applications.

What is a variator motor, and how does it differ from traditional motors?

A variator motor, also known as a variable speed motor, is a type of motor that allows for adjustable speed control. Unlike traditional motors that operate at a fixed speed, variator motors provide the ability to vary the rotational speed to meet specific application requirements. Here are some key points differentiating variator motors from traditional motors:

- Speed Control: The primary difference between variator motors and traditional motors is the ability to control the speed. Traditional motors typically operate at a fixed speed determined by the motor’s design and the frequency of the power supply. In contrast, variator motors feature mechanisms that allow for adjustable speed control, enabling users to increase or decrease the rotational speed as needed.

- Operating Principle: Variator motors achieve variable speed control through various mechanisms. One common approach is the use of adjustable transmission systems, such as variable frequency drives (VFDs) or mechanical gearboxes. These systems allow for changes in the motor’s output speed by adjusting the input power frequency or gear ratio. Other variator motors may employ electronic or hydraulic control systems to modulate the motor’s speed based on input signals or user commands.

- Application Flexibility: The ability to adjust the speed makes variator motors highly versatile and suitable for a wide range of applications. They can be employed in situations where precise speed control, energy efficiency, or the ability to adapt to changing operational requirements is critical. Variator motors find applications in industrial machinery, conveyors, pumps, fans, and other systems where speed modulation is beneficial.

- Energy Efficiency: Variator motors often exhibit higher energy efficiency compared to traditional motors, especially when operating at reduced speeds. By adjusting the motor’s speed to match the required output, variator motors can minimize energy wastage associated with running at fixed speeds. This energy-saving capability can lead to reduced operating costs and improved overall system efficiency.

- Cost and Complexity: Variator motors, due to their speed control capabilities, can be more complex and costly compared to traditional motors. The additional components required for speed modulation, such as variable frequency drives or control systems, can increase the overall system complexity and initial investment. However, the benefits of adjustable speed control and energy efficiency often outweigh the higher upfront costs in many applications.

In summary, a variator motor allows for adjustable speed control, enabling users to change the rotational speed to meet specific application requirements. With their ability to modulate speed, variator motors offer greater flexibility, energy efficiency, and application versatility compared to traditional motors.

editor by CX 2024-04-30

China manufacturer Udl Variable Stepless Speed Reducer Speed Reduction Motor with Hot selling

Product Description

You can choose the 1 type that you need form these product introction.

If you have any question,please contact me.

HangZhou CHINAMFG Machinery Co.,ltd is a company specialized in research, manufacture and service of speed gearbox. Ever since establishment, we have been persisting in technical innovation, advancing the techonology to our products while maintaining our strict quality controls. It is the reason that our products branding ”Xihu (West Lake) Dis.n” have enjoyed such successful global sales.

At present, our company mainly supplies 5 series products as RV worm gearbox, UDL series speed variator,PC series helical gear unit,G3 helical geared motor and SRC helical gearbox. The products are widely applied in the mechanical equipment field such as food and beverage,cement,package,chemical and dyeing, rubber and plastic, CNC machine tool,etc.

Our products have been processed ISO 9001 Quality System Certification and exported to Italy,Spain,Britain,Poland,Turkey.The USA and other European countries,earn the good reputation with our outstanding quality and service.

Customers first,customers satisfaction, excellent after sale service and incessant innovation are our tenet and motto. We will go all out to provide all the customers with high quality and service. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical and Horizontal |

| Samples: |

US$ 78/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can variator motors be integrated into automated systems, and how is this achieved?

Yes, variator motors can be integrated into automated systems, and their integration is achieved through various methods and technologies. Here’s an overview of how variator motors can be integrated into automated systems:

- Motor Control Interfaces: Variator motors can be equipped with motor control interfaces that allow them to communicate with automation systems. These interfaces can include analog inputs, digital inputs, and outputs, as well as communication protocols such as Modbus, Profibus, or Ethernet. By connecting the variator motor to the automation system through these interfaces, the motor can receive control signals and provide feedback, enabling seamless integration into the automated system.

- Programmable Logic Controllers (PLCs): PLCs are commonly used in automated systems to control and coordinate various components, including variator motors. The PLC can be programmed to send control signals to the variator motor based on the system’s requirements. The PLC can also receive feedback from the motor to monitor its status and adjust the control signals as needed. This integration allows for precise speed control, synchronization, and coordination of the variator motor with other system components.

- Industrial Communication Networks: In complex automated systems, variator motors can be integrated into industrial communication networks. These networks, such as Ethernet/IP, Profinet, or DeviceNet, enable communication and coordination between various devices, including variator motors, PLCs, human-machine interfaces (HMIs), and other automation components. Through these networks, control signals, data, and diagnostics can be exchanged, allowing for centralized control and monitoring of variator motors within the automated system.

- Sensor Integration: Variator motors can be integrated with various sensors to enhance the automation process. Sensors such as speed sensors, load sensors, temperature sensors, and position sensors can provide real-time data about the motor’s performance and the system’s operating conditions. This data can be used by the automation system to make informed decisions, adjust motor speed, optimize energy consumption, and ensure safe operation.

- Integration with Supervisory Control and Data Acquisition (SCADA) Systems: In larger-scale automated systems, variator motors can be integrated with SCADA systems. SCADA systems provide a comprehensive view of the entire automation process, allowing operators to monitor and control variator motors and other system components from a centralized location. SCADA systems enable real-time data visualization, historical data logging, alarm management, and remote access, enhancing the overall efficiency and reliability of the automated system.

By implementing these integration methods and technologies, variator motors can seamlessly become part of automated systems. The integration allows for precise control, monitoring, coordination, and optimization of variator motor performance, contributing to enhanced automation capabilities and improved overall system efficiency.

What are the key components and technologies used in modern variator motors?

Modern variator motors incorporate several key components and technologies to enable their variable speed and adjustable torque capabilities. Here’s a detailed explanation:

1. Motor Stator and Rotor: The motor stator and rotor are fundamental components of variator motors. The stator consists of a stationary set of windings that generate a rotating magnetic field when energized. The rotor, typically mounted on the motor shaft, contains conductive bars or coils that interact with the magnetic field and produce mechanical rotation.

2. Power Electronics: Variator motors rely on power electronics components, such as inverters or variable frequency drives (VFDs), to control the motor’s speed and torque. These devices convert the incoming AC power supply into the appropriate voltage and frequency required by the motor. Power electronics also enable smooth and precise adjustment of motor operating parameters, facilitating variable speed operation.

3. Sensors and Feedback Devices: Variator motors often incorporate sensors and feedback devices to monitor motor performance and provide input for control algorithms. Common sensors used include speed sensors, position sensors, temperature sensors, and current sensors. These sensors provide real-time information about the motor’s operating conditions, allowing the control system to adjust motor parameters accordingly.

4. Control Algorithms and Software: Modern variator motors employ sophisticated control algorithms and software to regulate motor speed, torque, and other operating parameters. These algorithms process the sensor data and generate control signals to adjust the power electronics and optimize motor performance. Advanced control techniques, such as field-oriented control (FOC) or model predictive control (MPC), may be used to achieve precise and efficient motor operation.

5. Variable Speed Drive Mechanisms: Variator motors employ various mechanisms to achieve variable speed operation. These mechanisms can include adjustable pulley systems, belt drives, gearboxes, or electronic control of motor winding configurations. The specific mechanism depends on the motor’s design and application requirements.

6. Efficiency-Enhancing Technologies: Modern variator motors incorporate technologies aimed at improving energy efficiency and reducing losses. These technologies may include the use of high-efficiency motor designs, such as permanent magnet motors or synchronous reluctance motors. Additionally, advanced insulation materials, optimized motor cooling systems, and reduced friction bearings can contribute to enhanced motor efficiency.

7. Communication and Networking: Some variator motors feature communication and networking capabilities to enable integration with industrial automation systems or the Internet of Things (IoT). These capabilities facilitate remote monitoring, control, and data exchange, allowing for enhanced motor performance analysis, predictive maintenance, and system integration.

8. Safety and Protection Features: Modern variator motors incorporate safety and protection features to safeguard the motor and the surrounding equipment. These features may include overcurrent protection, overvoltage protection, short-circuit protection, thermal protection, and fault detection mechanisms. These measures ensure safe and reliable operation and help prevent damage to the motor in case of abnormal operating conditions.

The specific components and technologies used in variator motors can vary depending on the motor’s type, design, and application requirements. Motor manufacturers continuously innovate and incorporate advancements in materials, electronics, and control systems to improve motor performance, efficiency, and reliability.

What is a variator motor, and how does it differ from traditional motors?

A variator motor, also known as a variable speed motor, is a type of motor that allows for adjustable speed control. Unlike traditional motors that operate at a fixed speed, variator motors provide the ability to vary the rotational speed to meet specific application requirements. Here are some key points differentiating variator motors from traditional motors:

- Speed Control: The primary difference between variator motors and traditional motors is the ability to control the speed. Traditional motors typically operate at a fixed speed determined by the motor’s design and the frequency of the power supply. In contrast, variator motors feature mechanisms that allow for adjustable speed control, enabling users to increase or decrease the rotational speed as needed.

- Operating Principle: Variator motors achieve variable speed control through various mechanisms. One common approach is the use of adjustable transmission systems, such as variable frequency drives (VFDs) or mechanical gearboxes. These systems allow for changes in the motor’s output speed by adjusting the input power frequency or gear ratio. Other variator motors may employ electronic or hydraulic control systems to modulate the motor’s speed based on input signals or user commands.

- Application Flexibility: The ability to adjust the speed makes variator motors highly versatile and suitable for a wide range of applications. They can be employed in situations where precise speed control, energy efficiency, or the ability to adapt to changing operational requirements is critical. Variator motors find applications in industrial machinery, conveyors, pumps, fans, and other systems where speed modulation is beneficial.

- Energy Efficiency: Variator motors often exhibit higher energy efficiency compared to traditional motors, especially when operating at reduced speeds. By adjusting the motor’s speed to match the required output, variator motors can minimize energy wastage associated with running at fixed speeds. This energy-saving capability can lead to reduced operating costs and improved overall system efficiency.

- Cost and Complexity: Variator motors, due to their speed control capabilities, can be more complex and costly compared to traditional motors. The additional components required for speed modulation, such as variable frequency drives or control systems, can increase the overall system complexity and initial investment. However, the benefits of adjustable speed control and energy efficiency often outweigh the higher upfront costs in many applications.

In summary, a variator motor allows for adjustable speed control, enabling users to change the rotational speed to meet specific application requirements. With their ability to modulate speed, variator motors offer greater flexibility, energy efficiency, and application versatility compared to traditional motors.

editor by CX 2024-04-09

China Good quality Udl Variable Stepless Speed Reducer Speed Reduction Motor vacuum pump distributors

Product Description

You can choose the 1 type that you need form these product introction.

If you have any question,please contact me.

HangZhou CHINAMFG Machinery Co.,ltd is a company specialized in research, manufacture and service of speed gearbox. Ever since establishment, we have been persisting in technical innovation, advancing the techonology to our products while maintaining our strict quality controls. It is the reason that our products branding ”Xihu (West Lake) Dis.n” have enjoyed such successful global sales.

At present, our company mainly supplies 5 series products as RV worm gearbox, UDL series speed variator,PC series helical gear unit,G3 helical geared motor and SRC helical gearbox. The products are widely applied in the mechanical equipment field such as food and beverage,cement,package,chemical and dyeing, rubber and plastic, CNC machine tool,etc.

Our products have been processed ISO 9001 Quality System Certification and exported to Italy,Spain,Britain,Poland,Turkey.The USA and other European countries,earn the good reputation with our outstanding quality and service.

Customers first,customers satisfaction, excellent after sale service and incessant innovation are our tenet and motto. We will go all out to provide all the customers with high quality and service. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical and Horizontal |

| Samples: |

US$ 78/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can variator motors be used in both fixed and variable speed applications?

Yes, variator motors can be used in both fixed and variable speed applications. Here’s a detailed explanation:

Variator motors, also known as variable speed motors or adjustable speed motors, are designed to provide flexibility in adjusting the motor’s speed according to the specific requirements of the application. This versatility allows them to be used in a wide range of applications, whether the desired speed is fixed or variable.

Here are some key points to consider regarding the use of variator motors in fixed and variable speed applications:

- Fixed Speed Applications: In fixed speed applications, where a constant speed is required throughout the operation, variator motors can still be used effectively. The motor can be set at the desired fixed speed during installation or through the control system. The advantage of using variator motors in fixed speed applications is that they often offer high efficiency and reliable performance, which can contribute to energy savings and reduced maintenance needs.

- Variable Speed Applications: Variator motors are particularly well-suited for variable speed applications, where the speed requirements may change based on different operational conditions or process demands. These motors allow for precise control over the motor’s speed, enabling optimization of the application’s performance. By adjusting the speed according to the specific requirements, variator motors can improve energy efficiency, enhance process control, reduce wear and tear on mechanical components, and enable better synchronization with other system elements.

- Speed Adjustment Range: Variator motors offer a wide range of adjustable speeds, allowing them to accommodate both fixed and variable speed applications. The speed adjustment range can vary depending on the specific model and type of variator motor. Some motors may have a limited range, while others can provide a broad range of speeds, spanning from low RPMs to high RPMs. When selecting a variator motor for a specific application, it’s essential to consider the required speed range and ensure that the motor can operate within those speed limits.

- Control Options: Variator motors often come with various control options that allow for easy adjustment of the motor’s speed. These control options can include manual control through potentiometers or dials, digital control through interface panels or keypads, or even programmable control through communication protocols such as Modbus or Ethernet. These control options facilitate the use of variator motors in both fixed and variable speed applications, as they provide flexibility in setting and changing the desired speed.

- Application Versatility: Variator motors are versatile and find applications in various industries and sectors. They can be used in applications such as conveyors, pumps, fans, compressors, mixers, machine tools, HVAC systems, robotics, and more. This versatility demonstrates how variator motors can be utilized effectively in both fixed and variable speed applications across different industries.

Overall, the use of variator motors offers flexibility and adaptability to meet the speed requirements of different applications, whether fixed or variable. By selecting the appropriate motor model, determining the desired speed range, and utilizing the available control options, variator motors can provide efficient and reliable performance in a wide range of applications.

What resources are available for further learning about the principles and applications of variator motors?

There are several resources available for further learning about the principles and applications of variator motors. Here’s a detailed explanation:

1. Books and Publications: Numerous books and publications cover the principles, design, and applications of variator motors. Some recommended titles include “Variable Speed AC Drives with Inverter Output Filters” by Jaroslaw Guzinski and Haitham Abu-Rub, “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and Bill Drury, and “Variable Frequency Drives: Installation and Troubleshooting” by Glen A. Mazur. These resources provide in-depth knowledge on variator motor technology, control strategies, and practical implementation.

2. Online Courses and Tutorials: Online learning platforms like Udemy, Coursera, and edX offer courses and tutorials on electric motors, motor control, and power electronics. These courses cover variator motor principles, operation, and applications, providing a structured learning experience with video lectures, quizzes, and assignments. Some courses are specifically focused on variable frequency drives (VFDs) and their applications.

3. Technical Documentation and Application Notes: Manufacturers of variator motors and associated equipment often provide technical documentation, application notes, and white papers that delve into the principles and applications of variator motors. These resources can be found on the manufacturers’ websites and offer valuable insights into motor selection, installation, and operation.

4. Professional Journals and Research Papers: Academic and professional journals in the fields of electrical engineering, power electronics, and industrial automation publish research papers and articles on variator motors. IEEE Transactions on Industrial Electronics, IEEE Industry Applications Magazine, and International Journal of Electrical Power & Energy Systems are some examples of publications that cover topics related to variator motors. Access to these resources may require subscriptions or membership in relevant professional organizations.

5. Webinars and Online Presentations: Webinars and online presentations hosted by motor manufacturers, industry associations, or technology companies can provide valuable insights into the principles and applications of variator motors. These events often feature subject matter experts who share their knowledge, discuss case studies, and answer questions from participants. Recordings of past webinars are sometimes made available for on-demand viewing.

6. Industry Forums and Discussion Groups: Online forums and discussion groups focused on electrical engineering, motor control, or industrial automation can be valuable resources for learning about variator motors. Platforms like Electrical Engineering Stack Exchange, Control.com, and LinkedIn groups dedicated to motor control offer opportunities to ask questions, engage in discussions, and learn from the experiences of industry professionals.

7. Manufacturer Training Programs: Some variator motor manufacturers offer training programs and workshops that cover the principles, operation, and applications of their products. These programs may include hands-on exercises, demonstrations, and technical support. Contacting the manufacturers directly or checking their websites can provide information on available training opportunities.

When exploring these resources, it’s important to consider the credibility of the source, relevance to specific applications, and the date of publication to ensure the information aligns with the latest advancements in variator motor technology.

By utilizing these resources, individuals can deepen their understanding of variator motors and enhance their knowledge of the principles and applications associated with this technology.

Can you explain the principle behind the variable speed control in variator motors?

The variable speed control in variator motors is achieved through various mechanisms depending on the specific type of variator motor. Here, we’ll explore a few common principles behind variable speed control:

- Adjustable Transmission Systems: Many variator motors utilize adjustable transmission systems to achieve variable speed control. One common example is the use of variable frequency drives (VFDs) in electric motors. VFDs facilitate speed control by adjusting the frequency of the electrical power supplied to the motor. By modifying the frequency, the VFD can change the rotational speed of the motor. Another example is the use of mechanical gearboxes with different gear ratios. By selecting different gears, the input speed can be converted to various output speeds, allowing for speed control.

- Electronic Control Systems: Some variator motors employ electronic control systems to achieve variable speed control. These control systems typically consist of microprocessors, sensors, and feedback mechanisms. The motor speed is adjusted based on input signals or commands received by the control system. The control system then modulates the power supplied to the motor to achieve the desired speed. This approach is often used in applications where precise speed control and automation are required.

- Hydraulic Control Systems: In hydraulic variator motors, speed control is achieved through hydraulic control systems. These systems use hydraulic pumps, valves, and actuators to adjust the motor speed. By controlling the flow rate and pressure of the hydraulic fluid, the speed of the motor can be modulated. Hydraulic variator motors are commonly used in applications where high torque and ruggedness are required, such as heavy machinery and construction equipment.

Regardless of the specific mechanism used, the principle behind variable speed control in variator motors involves adjusting the input power, transmission, or control system to modify the rotational speed of the motor. This flexibility in controlling the speed allows for precise matching of the motor’s output to the requirements of the application, resulting in improved efficiency, reduced energy consumption, and enhanced performance.

editor by CX 2024-03-14

China Good quality Udl Variable Stepless Speed Reducer Speed Reduction Motor with Good quality

Product Description

You can choose the 1 type that you need form these product introction.

If you have any question,please contact me.

HangZhou CHINAMFG Machinery Co.,ltd is a company specialized in research, manufacture and service of speed gearbox. Ever since establishment, we have been persisting in technical innovation, advancing the techonology to our products while maintaining our strict quality controls. It is the reason that our products branding ”Xihu (West Lake) Dis.n” have enjoyed such successful global sales.

At present, our company mainly supplies 5 series products as RV worm gearbox, UDL series speed variator,PC series helical gear unit,G3 helical geared motor and SRC helical gearbox. The products are widely applied in the mechanical equipment field such as food and beverage,cement,package,chemical and dyeing, rubber and plastic, CNC machine tool,etc.

Our products have been processed ISO 9001 Quality System Certification and exported to Italy,Spain,Britain,Poland,Turkey.The USA and other European countries,earn the good reputation with our outstanding quality and service.

Customers first,customers satisfaction, excellent after sale service and incessant innovation are our tenet and motto. We will go all out to provide all the customers with high quality and service.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical and Horizontal |

| Samples: |

US$ 78/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What factors should be considered when selecting a variator motor for a specific application?

When selecting a variator motor for a specific application, several factors should be considered to ensure optimal performance and compatibility. Here are some key factors to take into account:

- Load Characteristics: Consider the specific characteristics of the load the motor will be driving. This includes factors such as the torque requirements, speed range, and variations in load demand. Understanding the load characteristics helps in selecting a variator motor with the appropriate power and speed capabilities to meet the application’s requirements.

- Speed Range: Determine the required speed range for the application. Variator motors offer the advantage of adjustable speed control, but different models may have different speed ranges. Ensure that the selected variator motor can operate within the desired speed range to meet the application’s needs.

- Power Rating: Consider the power rating required by the application. This involves assessing the motor’s ability to deliver the necessary torque and power output to drive the load effectively. It’s important to select a variator motor that can handle the power requirements of the application without operating at its maximum capacity continuously.

- Environmental Conditions: Evaluate the environmental conditions in which the variator motor will operate. Factors such as temperature, humidity, dust, vibrations, and corrosive substances can impact motor performance and longevity. Choose a variator motor that is designed to withstand the specific environmental conditions of the application, such as motors with appropriate protection ratings or specialized coatings.

- Efficiency and Energy Savings: Consider the desired energy efficiency of the system. Variator motors can offer energy savings through adjustable speed control, but efficiency levels can vary between models. Look for motors with high efficiency ratings, such as those meeting energy efficiency standards like IE3 or IE4, to optimize energy consumption and reduce operating costs.

- Control and Integration Requirements: Assess the control and integration needs of the application. Determine whether the variator motor requires specific control interfaces or communication protocols to integrate with the automation system effectively. Consider compatibility with existing control systems, such as programmable logic controllers (PLCs) or industrial communication networks, to ensure seamless integration and ease of operation.

- Reliability and Maintenance: Evaluate the reliability and maintenance requirements of the variator motor. Consider factors such as the expected lifespan, durability of components, availability of spare parts, and ease of maintenance. Choosing a motor from a reputable manufacturer with a track record of reliable products and good customer support can help ensure long-term performance and minimize downtime.

- Cost Considerations: Finally, consider the cost of the variator motor, including the initial purchase cost as well as long-term operating costs. While it’s important to find a motor that meets the application’s requirements, it’s also essential to consider the overall cost-effectiveness and return on investment. This includes factors such as energy savings, maintenance costs, and potential productivity gains.

By carefully considering these factors, you can select a variator motor that is well-suited to the specific application, delivering optimal performance, energy efficiency, and reliability.

What resources are available for further learning about the principles and applications of variator motors?

There are several resources available for further learning about the principles and applications of variator motors. Here’s a detailed explanation:

1. Books and Publications: Numerous books and publications cover the principles, design, and applications of variator motors. Some recommended titles include “Variable Speed AC Drives with Inverter Output Filters” by Jaroslaw Guzinski and Haitham Abu-Rub, “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and Bill Drury, and “Variable Frequency Drives: Installation and Troubleshooting” by Glen A. Mazur. These resources provide in-depth knowledge on variator motor technology, control strategies, and practical implementation.

2. Online Courses and Tutorials: Online learning platforms like Udemy, Coursera, and edX offer courses and tutorials on electric motors, motor control, and power electronics. These courses cover variator motor principles, operation, and applications, providing a structured learning experience with video lectures, quizzes, and assignments. Some courses are specifically focused on variable frequency drives (VFDs) and their applications.

3. Technical Documentation and Application Notes: Manufacturers of variator motors and associated equipment often provide technical documentation, application notes, and white papers that delve into the principles and applications of variator motors. These resources can be found on the manufacturers’ websites and offer valuable insights into motor selection, installation, and operation.

4. Professional Journals and Research Papers: Academic and professional journals in the fields of electrical engineering, power electronics, and industrial automation publish research papers and articles on variator motors. IEEE Transactions on Industrial Electronics, IEEE Industry Applications Magazine, and International Journal of Electrical Power & Energy Systems are some examples of publications that cover topics related to variator motors. Access to these resources may require subscriptions or membership in relevant professional organizations.

5. Webinars and Online Presentations: Webinars and online presentations hosted by motor manufacturers, industry associations, or technology companies can provide valuable insights into the principles and applications of variator motors. These events often feature subject matter experts who share their knowledge, discuss case studies, and answer questions from participants. Recordings of past webinars are sometimes made available for on-demand viewing.

6. Industry Forums and Discussion Groups: Online forums and discussion groups focused on electrical engineering, motor control, or industrial automation can be valuable resources for learning about variator motors. Platforms like Electrical Engineering Stack Exchange, Control.com, and LinkedIn groups dedicated to motor control offer opportunities to ask questions, engage in discussions, and learn from the experiences of industry professionals.

7. Manufacturer Training Programs: Some variator motor manufacturers offer training programs and workshops that cover the principles, operation, and applications of their products. These programs may include hands-on exercises, demonstrations, and technical support. Contacting the manufacturers directly or checking their websites can provide information on available training opportunities.

When exploring these resources, it’s important to consider the credibility of the source, relevance to specific applications, and the date of publication to ensure the information aligns with the latest advancements in variator motor technology.

By utilizing these resources, individuals can deepen their understanding of variator motors and enhance their knowledge of the principles and applications associated with this technology.

Are there specific types of variator motors designed for certain tasks or environments?

Yes, there are specific types of variator motors that are designed to suit certain tasks or operate effectively in specific environments. Here are some examples:

- Variable Frequency Drives (VFDs): VFDs are a type of variator motor designed for electric motors. They are widely used in various industrial applications and are particularly suited for tasks that require precise speed control. VFDs allow for adjustable speed by varying the frequency of the electrical power supplied to the motor. They are commonly utilized in applications such as pumps, fans, conveyors, and machine tools.

- Hydraulic Variator Motors: Hydraulic variator motors are designed for applications that require high torque and ruggedness. They are commonly used in heavy machinery, construction equipment, and industrial processes where hydraulic power is readily available. Hydraulic variators control the motor speed by adjusting the flow rate and pressure of the hydraulic fluid, allowing for variable speed operation in demanding environments.

- Variable Transmission Systems: Some variator motors are designed with variable transmission systems, such as mechanical gearboxes. These motors are suitable for applications that require adjustable speed through gear ratio changes. They are commonly used in automotive applications, industrial machinery, and equipment that benefit from mechanical speed control mechanisms.

- Electronically Controlled Variator Motors: Certain variator motors incorporate advanced electronic control systems to achieve variable speed control. These motors are often used in automation and robotics applications, where precise and programmable speed control is essential. The electronic control systems allow for integration with other control systems and enable sophisticated control algorithms to optimize performance.

- Explosion-proof Variator Motors: In hazardous environments where the presence of flammable gases or dust is a concern, explosion-proof variator motors are designed to meet strict safety standards. These motors are constructed with special enclosures, seals, and components that prevent the ignition of hazardous substances. They are commonly used in industries such as oil and gas, chemical processing, and mining.

These are just a few examples of specific types of variator motors designed for particular tasks or environments. It’s important to select the appropriate variator motor that meets the requirements of the specific application, taking into consideration factors such as speed range, load characteristics, environmental conditions, safety considerations, and regulatory compliance.

editor by CX 2023-12-06

china Cheap B/Jxj Series High Speed Reduction Ratios manufacturers

Merchandise Description

Starshine CZPT Cycloid Geared CZPT Characteristics

1. Features:

one. Smooth running,low noise equipment tooth needle a lot more engagement.

two. Cycloidal tooth profile supplies a higher get in touch with ratio to face up to overload shocks

3. Compact measurement: one ratio CZPT from 1/9 to 1/87, double stage up from 1/99 to 1/7569

four. CZPT for dynamic applications: frequent commence-end-reversing responsibilities suits for cyclo pace reducer considering that inertia is minimal

five. Decrease routine maintenance fees: high dependability, CZPT existence, minimum maintenance when compared to typical gearboxes

6. Interior elements replaceable with other brand names to make certain working.

seven. Grease Lubricated & Oil Lubricated Types Offered

8. Output Shaft Rotation Path: One Reduction: Clockwise Rotation Double Reduction→ Counter Clockwise Rotation

nine. Ambient Conditions: Indoor Set up:ten-40 Celsius, CZPT eighty five% Humidity, Below 1000m Altitude, Nicely Ventilated CZPT , Free of corrosive, explosive gases, vapors and dust

10.Gradual CZPT Shaft Course: Horizontal, Vertical Up & Down, CZPT Direction

11.Mounting CZPT : Foot Mount, Flange Mount & Vertical F-flange Mount,

12. Input Relationship: Cyclo Integral CZPT , Hollow Input Shaft Adapter

thirteen. CZPT Approach With CZPT n CZPT : CZPT , Gears, Chain CZPT Or Belt

14. Cycloid reducer Capability Variety: .37kW ~ 11kW

2. CZPT nical parameters

| Type | Previous Kind | Output Torque | Output Shaft Dia. |

| SXJ00 | JXJ00 | 98N.m | φ30 |

| SXJ01 | JXJ01 | 221N.m | φ35 |

| SXJ02 | JXJ02 | 448N.m | φ45 |

| SXJ03 | JXJ03 | 986N.m | φ55 |

| SXJ04 | JXJ04 | 1504N.m | φ70 |

| SXJ05 | JXJ05 | 3051N.m | φ90 |

| SXJ06 | JXJ06 | 5608N.m | φ100 |

About Us

ZheJiang CZPT glow CZPT Co.,Ltd,the predecessor was a state-owned military mould organization, was recognized in 1965. CZPT glow specializes in the full CZPT transmission solution for substantial-conclude equipment production industries based mostly on the purpose of “Platform Item, Software Design and style and Specialist Services”.

Starshine have a sturdy technological drive with in excess of 350 personnel at present, like above 30 CZPT experts, 30 quality inspectors, covering an location of 80000 square meters and types of CZPT d processing machines and screening equipments. We have a excellent foundation for the market application development and service of higher-stop speed reducers & variators possessing to the provincial CZPT technological innovation study heart,the lab of equipment pace reducers, and the foundation of modern R&D.

Our Staff

Quality Manage

Quality:Insist on Improvement,Strive for Excellence With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of excellence

Quality Philosophy:Quality creates value

3. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection responsible for tracking bad, to monitor the supplier to take corrective

measures to prevent recurrence.

four. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend

found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state.

5. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer’s position on the finished product quality verification, in order to ensure the quality of

customer expectations and needs.

6. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the

item is a product inspection to determine the qualified products.

seven. Certification.

Packing

Shipping and delivery

DC motors use vitality from batteries or other creating sources that give a consistent voltage. A DC motor consists of numerous components, the most well-known of which consist of bearings, shafts, and gearboxes or gears. DC motors supply greater pace variation and management and create more torque than AC motors. The two types of DC motors incorporate Brushed motors: Brushed motors are a single of the oldest varieties and are internally commutated motors pushed by DC recent. A brushed motor is made up of a rotor, brushes, and a shaft. The demand and polarity of the brushes control the path and velocity of the motor. Brushless Motors: In modern years, brushless motors have become well-known for several programs, primarily simply because of their efficiency. Brushless motors are built in the very same way as brushed motors, minus the brushes of training course. Brushless motors also incorporate focused circuitry to handle speed and direction. In brushless motors, magnets are mounted all around the rotor, an effectiveness-boosting configuration.

china sales Factory Supply Advance Marine Speed Reduction Gearbox 300 for Weichai Marine Engine manufacturers

Item Description

Merchandise Description

HangZhou CZPT MA125 Gearbox

HangZhou CZPT generates the ideal gearbox in CZPT .

The 120C marine gearbox is suited for tiny and medium-sized substantial speed boats this sort of as yachts, cargo ships, passenger ships and other types of vessels. It is able of decelerating speed, reversing clutch path and bearing propeller thrust. The 120C gearbox has a modest size, a big velocity ratio and a light excess weight and can be matched with high-pace motor to form a maritime CZPT device.

Solution Parameters

| Enter CZPT | 1500~3000r/min | ||

| Reduction Ratio (i) | 2.03,2.forty six | Transmission Capacity (kW/r/min) | .02 |

| 3.04 | .018 | ||

| 3.57 | .016 | ||

| 4.05 | .014 | ||

| 4.39 | .013 | ||

| four.seven | .011 | ||

| Maneuver Type | Push-pull versatile Shaft | ||

| Centre Distance | 125mm | ||

| Rated Thrust | 5.5KN | ||

| L×W×H | 291*454*485mm | ||

| Net CZPT ght | 115kg | ||

| Coupling Flywheel | SAE 11.5/ten | ||

| Coupling Housing | SAE 2/3/4 | ||

| Functions AT A Glance |

Superior CZPT nology Compact Construction Vast Applicability High CZPT bility

Great Maintainability

|

||

Product Configuration

Personalize YOUR Machine

Oil Pressure Gauge and CZPT Unit

Oil Temperature Gauge and CZPT System

SAE Flywheel Housing Possibilities

Hydraulic Stress Minimal CZPT

Solenoid Managed Change

…….

Make contact with US FOR Far more Information YOU Want!

Company Profile

HangZhou LionHeart CZPT Gear Co., Ltd., a subsidiary of one particular of the nation’s prime maritime providers business —- HangZhou Agricultural CZPT ry Co., Ltd., is a supplier of marine products CZPT . Our organization is fully commited to offering the greatest resolution to CZPT CZPT er’s task since 1996. With over 20 a long time of profound encounter in the marine solutions business, CZPT company has set up a expert and CZPT er-pleasant technique in CZPT every single pre-income, shipping and right after-income process to ensure your fear-totally free purchasing experience. We ship CZPT brand name-new items all above the entire world, at the greatest charges on the Internet.

LionHeart CZPT is a professional provider for equipment like marine engines, turbines, gearboxes, propellers, marine inside fit-out, deck equipment and associated marine spare parts. Our procedures and procedures are developed to current the perfect item that will fulfill or exceed the expectations of each and every a single of CZPT CZPT ers. We back up that determination with complete services through the product’s whole daily life cycle, together with CZPT important systems and foremost product experience. That is the cause why we stand out as the nation’s marine equipment sales champion of numerous manufacturers for above 10 consecutive many years.

LionHeart CZPT carries one of the nation’s largest inventories of maritime equipment and connected areas from 20+ manufacturers such as CZPT chai, HangZhou CZPT , CZPT , Steyr, Zichai, CZPT and a lot more, amongst which the CZPT and CZPT series are totally coated. Especially, that stock is meticulously structured in excess of 57 acres exterior and 118, 000 sq. FT. Of warehouse below roof. That means CZPT goods are usually in inventory for fast availability. Aside from, we are proud of CZPT source plHangZhou method of products, which is unparalleled in the sector, providing you the shortest guide time and effective provider.

LionHeart CZPT ‘s employees is expertly qualified not only to rapidly track down the products you are hunting for, but also to satisfy your venture specifications with the very best remedy. If what you are seeking for is not ‘on the shelf’, we will CZPT ize it for you. This energy builds upon CZPT strong partnership with CZPT producers and manufacturing institutes. Performance and support are the targets of each and every member of CZPT organization. LionHeart CZPT is aware your time is useful and we create this worth for you. High quality products and expertly-trained provider technicians, mixed with CZPT comprehensive inventory, give you the edge in your commercial and industrial achievement.

Certifications

Generation procedure

Packaging & CZPT

FAQ

1.Processing

Orders are generally packed and all set to ship in 1 to 3 business times if the goods are in stock. Nonetheless shipments are subiect to required manufacturing time and CZPT s clearance techniques. which can cause delays beyond authentic delivery estimates. For thorough shipping info, remember to speak to CZPT er services.

2.Packing Techniques

Typically we use wooden bins for packaging or we can pack it in accordance to your particular wants.

3.Transport Methods

We are happy to provide a variety of delivery methods. CZPT methods CZPT : EXW. FOB.CER. CIF.

4. CZPT Returns & Exchanges

Unfortunately we are unable to take retums on intemational orders. We will examination each product before dellverv One-yr manufacturer warranty is quaranteed on CZPT complete devices and 3 months on spare elements. I1 you have any considerations with your get, please reach out to CZPT er services

five.Payment Strategies

We sugqest fifty/fifty T/T payment strategy: fifty p.c down payment on placement of the get, with the remaining 50% due upon cargo. We also accept L/C, CZPT Assurance, Visa transfer and Paypal

An AC motor is a sort of motor that utilizes the phenomenon of electromagnetic induction. AC energy drives the motor. It is a present that periodically reverses route and changes its magnitude of the current over time. This existing is the opposite of a direct existing or “DC” which flows in only a single route. AC motors can supply a reasonably successful way to produce mechanical strength from a basic electrical input sign.

china Cost Energy Saving Trc Series Speed Reduction Gearbox Helical Gear Reducer manufacturers

Merchandise Description

Solution Description

KPC Collection CZPT cal gearbox is a new technology product which designed basing on the modular system, It can be related respectively with motors these kinds of as IEC regular motor, brake motor, explosion-proof motor, frequency motor, servo motor and so on. it has 4 types(01-02-03-04),power from .12kw to 4.0kw, ratio from 3.66 to fifty eight.09, CZPT torque from 120Nm to 500Nm.It can be join discretionary(foot or flange) and use multi-mounting positions appropriately. This solution is extensively employed in textile, foodstuff, beverage,tobacco, logistics industrial fields,and so on.

Product Qualities

- Modular construction

- Higher performance

- Exact grinding, low sounds

- Compact structural design and style

- Univeral mounting

- Aluminium housing, gentle in weight

- Carbonize and grinding hardened gears, resilient

- Multi-structure, can be combined in distinct forms to meet up with CZPT transmission condition

Installation:

1.Foot mounted

2.Output Flange mounted

3.B14 Flange mounted

Models:

1.KPC..P(Foot-mounted): KPC01P,KPC02P,KPC03P,KPC04P

2.KPCF..P(Output Flange-mounted): KPCF01P,KPCF02P,KPCF03P,KPCF04P

3.KPCZ..P(B14 Flange-mounted): KPCZ01P,KPCZ02P,KPCZ03P,KPCZ04P

In depth Images

Item Parameters

| GEARBOX Choosing TABLES | |||||||||

| KPC01.. | n1=1400r/min | 120Nm | |||||||

| n2 | M2max | Fr2 | i | Proportion | 63B5 | 71B5/B14 | 80B5/B14 | 90B5/B14 | |

| [r/min] | [Nm] | [N] | |||||||

| 26 | one hundred twenty | 2600 | fifty three.33 | 160/three | |||||

| 31 | 120 | 2600 | 45.89 | 413/9 | |||||

| 35 | a hundred and twenty | 2600 | forty.10 | 3248/81 | |||||

| 39 | a hundred and twenty | 2560 | 35.47 | 532/15 | |||||

| 49 | one hundred twenty | 2380 | 28.50 | 770/27 | |||||

| 59 | a hundred and twenty | 2230 | 23.56 | 212/nine | |||||

| seventy one | a hundred and twenty | 2100 | 19.83 | 119/six | |||||

| seventy eight | ninety | 2030 | 17.86 | 1357/seventy six | |||||

| ninety six | a hundred and twenty | 1900 | 14.62 | 658/forty five | |||||

| 101 | 90 | 1860 | thirteen.eighty* | 69/5 | |||||

| 118 | 120 | 1770 | eleven.90 | 2464/207 | |||||

| 143 | 120 | 1660 | nine.81 | 1148/117 | |||||

| 153 | eighty | 1630 | 9.17 | 1219/133 | |||||

| 181 | 80 | 1540 | 7.72 | 1173/152 | |||||

| 246 | 70 | 1390 | five.69 | 1081/one hundred ninety | |||||

| 302 | 70 | 1290 | 4.63 | 88/19 | |||||

| 366 | 70 | 1210 | 3.82 | 943/247 | |||||

| KPC02.. | n1=1400r/min | 200Nm | |||||||

| n2 | M2max | Fr2 | i | Proportion | 63B5 | 71B5/B14 | 80B5/B14 | 90B5/B14 | |

| [r/min] | [Nm] | [N] | |||||||

| 26 | 200 | 4500 | fifty four.00* | fifty four/one | |||||

| 30 | 200 | 4500 | forty six.forty six* | 3717/80 | |||||

| 34 | 200 | 4500 | forty.60* | 203/5 | |||||

| 39 | 200 | 4270 | 35.91* | 3591/one hundred | |||||

| forty eight | 200 | 3970 | 28.88* | 231/8 | |||||

| fifty nine | 200 | 3730 | 23.eighty five* | 477/twenty | |||||

| 70 | two hundred | 3520 | 20.08* | 3213/160 | |||||

| 82 | a hundred and forty | 3330 | seventeen.10 | 3009/176 | |||||

| ninety five | 200 | 3180 | fourteen.eighty one* | 2961/200 | |||||

| 106 | one hundred forty | 3060 | thirteen.21 | 2907/220 | |||||

| 116 | 200 | 2970 | twelve.05 | 1386/a hundred and fifteen | |||||

| 141 | 200 | 2780 | 9.93 | 2583/260 | |||||

| 159 | one hundred twenty | 2670 | eight.78 | 2703/308 | |||||

| 189 | one hundred twenty | 2520 | seven.39 | 2601/352 | |||||

| 257 | one hundred | 2280 | 5.45 | 2397/440 | |||||

| 316 | a hundred | 2120 | four.43 | 102/23 | |||||

| 383 | eighty | 1990 | 3.66 | 2091/572 | |||||

| KPC03.. | n1=1400r/min | 300Nm | |||||||

| n2 | M2max | Fr2 | i | Proportion | 71B5/B14 | 80B5/B14 | 90B5/B14 | 100B5/B14 | 112B5/B14 |

| [r/min] | [Nm] | [N] | |||||||

| 24 | three hundred | 6000 | fifty eight.09 | 639/11 | |||||

| 28 | 300 | 6000 | fifty.02 | 2201/forty four | |||||

| 32 | 300 | 6000 | forty three.75 | 4331/ninety nine | |||||

| 36 | three hundred | 6000 | 38.73 | 426/eleven | |||||

| forty | three hundred | 5860 | 34.62 | 4189/121 | |||||

| 49 | three hundred | 5480 | 28.30 | 4047/143 | |||||

| sixty four | 280 | 5571 | 21.78 | 1917/88 | |||||

| eighty one | 280 | 4660 | seventeen.33 | 3621/209 | |||||

| ninety three | 260 | 4440 | fifteen.06 | 497/33 | |||||

| 113 | 260 | 4160 | twelve.37 | 1633/132 | |||||

| 136 | 240 | 3910 | ten.28 | 3053/297 | |||||

| 177 | one hundred eighty | 3590 | 7.93 | 1269/160 | |||||

| 222 | 180 | 3320 | 6.31 | 2397/380 | |||||

| 255 | 150 | 3170 | five.48 | 329/sixty | |||||

| 311 | one hundred fifty | 2970 | 4.50 | 1081/240 | |||||

| 374 | one hundred fifty | 2790 | 3.74 | 2571/540 | |||||

| KPC04.. | n1=1400r/min | 500Nm | |||||||

| n2 | M2max | Fr2 | i | Proportion | 80B5/B14 | 90B5/B14 | 100B5/B14 | 112B5/B14 | |

| [r/min] | [Nm] | [N] | |||||||

| 24 | five hundred | 8000 | 58.09 | 639/eleven | |||||

| 28 | five hundred | 8000 | fifty.02 | 2201/forty four | |||||

| 32 | 500 | 8000 | forty three.75 | 4331/99 | |||||

| 36 | 500 | 8000 | 38.73 | 426/11 | |||||

| forty | five hundred | 7950 | 34.62 | 4189/121 | |||||

| 49 | five hundred | 7430 | 28.30 | 4047/143 | |||||

| 64 | 480 | 6810 | 21.78 | 1917/88 | |||||

| eighty one | 480 | 6310 | 17.33 | 3621/209 | |||||

| ninety three | 460 | 6571 | fifteen.06 | 497/33 | |||||

| 113 | 460 | 5640 | twelve.37 | 1633/132 | |||||

| 136 | 440 | 5300 | 10.28 | 3053/297 | |||||

| 177 | 260 | 4860 | seven.93 | 1269/one hundred sixty | |||||

| 222 | 260 | 4510 | six.31 | 2397/380 | |||||

| 255 | 230 | 4300 | five.48 | 329/60 | |||||

| 311 | 230 | 4030 | four.50 | 1081/240 | |||||

| 374 | 200 | 3780 | three.74 | 2571/540 | |||||

Define Dimension:

Organization Profile

About CZPT company:

We are a professional reducer company located in HangZhou, ZHangZhoug province.Our major items is full range of RV571-a hundred and fifty worm reducers , also provided hypoid CZPT cal gearbox, Pc models, UDL Variators and AC CZPT s.Products are commonly utilized for purposes this kind of as: foodstuffs, ceramics, packing, chemical substances, pharmacy, plastics, paper-creating, construction equipment, metallurgic mine, environmental security CZPT , and all types of computerized traces, and assembly traces.With CZPT shipping, superior following-sales support, CZPT d generating facility, CZPT goods market well both at property and abroad. We have exported CZPT reducers to CZPT Asia, CZPT ern CZPT pe and Center CZPT and so on.Our intention is to create and innovate on foundation of high top quality, and generate a good reputation for reducers.

Packing details:Plastic Bags+Cartons+Wood Cases , or on request

We participate Germany Hannver Exhibition-ZheJiang PTC Fair-Turkey Acquire Eurasia

Logistics

We can dispatch goods by sea, by train, by air in accordance to CZPT er instruction

Right after Product sales Services

one.Routine maintenance Time and Guarantee:In one particular yr right after getting goods.

two.Other Provider: Such as modeling assortment manual, installation manual, and difficulty resolution information, etc.

FAQ

1.Q:Can you make as for every CZPT er drawing?

A: Sure, we provide CZPT ized service for CZPT ers appropriately. We can use CZPT er’s nameplate for gearboxes.

two.Q:What is your conditions of payment ?

A: 30% deposit ahead of generation,harmony T/T prior to shipping.

3.Q:Are you a trading business or producer?

A:We are a manufacurer with CZPT d gear and knowledgeable employees.

four.Q:What’s your creation capacity?

A:8000-9000 PCS/Month

five.Q:Free sample is CZPT or not?

A:Yes, we can provide free of charge sample if CZPT er concur to pay out for the courier price

6.Q:Do you have any certificate?

A:Yes, we have CE certificate and SGS certification report.

Get in touch with data:

Ms Lingel Pan

For any inquiries just truly feel free of charge ton speak to me. A lot of many thanks for your kind focus to CZPT company!

These NEMA c-airplane reducers are gear energy, servicing-totally free, and can be put in in any orientation with a slip match “O” ring style. Available in minimal to substantial reduction ratios, flange mount or base mount styles, appropriate angle or hollow shaft appropriate angle variations. Install NEMA C-Face AC motors, brushless DC motors, and brushed DC motors. For 1/2 HP to 3 HP Motors NEMA 56C, 140TC, and 180TC Enter Flange Inline Helical Equipment Reducers Proper Angle Hypoid Equipment Reducers

china wholesaler Aluminium Nmrv Motovario Worm Gear Box for Speed Reduction manufacturers

Product Description

Item Description

Main CZPT :

one)housing:aluminium alloy ADC12(size 571-090) die forged iron HT200(dimensions a hundred and ten-a hundred and fifty)

2)Worm:20Cr, ZI Involute profile carbonize&quencher warmth therapy make equipment surface area hardness up to 56-62 HRC Right after precision grinding, carburization layer’s thickness between .3-.5mm.

three)Worm Wheel:wearable stannum alloy CuSn10-1

In depth Photographs

Combination Possibilities:

Input:with enter shaft, With square flange,With IEC standard input flange

Output:with torque arm, output flange, one output shaft, double output shaft, plastic cover

Worm reducers are CZPT with diffferent mixtures: NMRV+NMRV, NMRV+NRV, NMRV+Personal computer, NMRV+UDL, NMRV+MOTORS

Exploded View:

Merchandise Parameters

| Previous Model |

New Model | Ratio | Center Distance | Energy | Input Dia. | Output Dia. | Output Torque | Bodyweight |

| RV571 | 7.5~100 | 25mm | .06KW~.12KW | Φ9 | Φ11 | 21N.m | .7kgs | |

| RV030 | RW030 | seven.5~100 | 30mm | .06KW~.25KW | Φ9(Φ11) | Φ14 | 45N.m | one.2kgs |

| RV040 | RW040 | 7.5~a hundred | 40mm | .09KW~.55KW | Φ9(Φ11,Φ14) | Φ18(Φ19) | 84N.m | 2.3kgs |

| RV050 | RW050 | seven.5~one hundred | 50mm | .12KW~1.5KW | Φ11(Φ14,Φ19) | Φ25(Φ24) | 160N.m | three.5kgs |

| RV063 | RW063 | 7.5~one hundred | 63mm | .18KW~2.2KW | Φ14(Φ19,Φ24) | Φ25(Φ28) | 230N.m | 6.2kgs |

| RV075 | RW075 | 7.5~a hundred | 75mm | .25KW~4.0KW | Φ14(Φ19,Φ24,Φ28) | Φ28(Φ35) | 410N.m | nine.0kgs |

| RV090 | RW090 | seven.5~100 | 90mm | .37KW~4.0KW | Φ19(Φ24,Φ28) | Φ35(Φ38) | 725N.m | thirteen.0kgs |

| RV110 | RW110 | 7.5~one hundred | 110mm | .55KW~7.5KW | Φ19(Φ24,Φ28,Φ38) | Φ42 | 1050N.m | 35.0kgs |

| RV130 | RW130 | 7.5~a hundred | 130mm | .75KW~7.5KW | Φ24(Φ28,Φ38) | Φ45 | 1550N.m | forty eight.0kgs |

| RV150 | RW150 | seven.5~one hundred | 150mm | 2.2KW~15KW | Φ28(Φ38,Φ42) | Φ50 | eighty four.0kgs |

GMRV Define Dimension:

| GMRV | A | B | C | C1 | D(H8) | E(h8) | F | G | G1 | H | H1 | I | M | N | O | P | Q | R | S | T | BL | β | b | t | V |

| 030 | 80 | ninety seven | 54 | forty four | fourteen | fifty five | 32 | 56 | sixty three | sixty five | 29 | 55 | 40 | 57 | 30 | 75 | 44 | six.5 | 21 | 5.five | M6*10(n=4) | 0° | five | sixteen.3 | 27 |

| 040 | one hundred | 121.5 | 70 | sixty | eighteen(19) | sixty | 43 | seventy one | 78 | seventy five | 36.five | 70 | fifty | seventy one.five | 40 | 87 | 55 | six.5 | 26 | six.five | M6*ten(n=4) | 45° | 6 | twenty.8(21.8) | 35 |

| 050 | 120 | 144 | eighty | 70 | 25(24) | 70 | 49 | eighty five | ninety two | 85 | forty three.five | 80 | sixty | eighty four | fifty | one hundred | 64 | 8.5 | 30 | seven | M8*12(n=4) | 45° | 8 | 28.3(27.3) | forty |

| 063 | a hundred and forty four | 174 | a hundred | eighty five | 25(28) | eighty | 67 | 103 | 112 | 95 | fifty three | 95 | 72 | 102 | sixty three | 110 | 80 | eight.5 | 36 | 8 | M8*twelve(n=8) | 45° | eight | 28.3(31.3) | fifty |

| 075 | 172 | 205 | 120 | ninety | 28(35) | ninety five | 72 | 112 | one hundred twenty | one hundred fifteen | 57 | 112.5 | 86 | 119 | seventy five | one hundred forty | ninety three | eleven | 40 | 10 | M8*14(n=8) | 45° | 8(ten) | 31.3(38.3) | 60 |

| 090 | 206 | 238 | a hundred and forty | one hundred | 35(38) | a hundred and ten | 74 | one hundred thirty | 140 | 130 | 67 | 129.five | 103 | a hundred thirty five | 90 | one hundred sixty | 102 | thirteen | forty five | eleven | M10*16(n=8) | 45° | 10 | 38.3(forty one.3) | 70 |

| 110 | 255 | 295 | a hundred and seventy | 115 | 42 | a hundred thirty | – | a hundred and forty four | 155 | 165 | 74 | one hundred sixty | 127.5 | 167.5 | a hundred and ten | two hundred | a hundred twenty five | fourteen | fifty | 14 | M10*eighteen(n=8) | 45° | 12 | 45.3 | eighty five |

| a hundred thirty | 293 | 335 | two hundred | a hundred and twenty | 45 | one hundred eighty | – | 155 | one hundred seventy | 215 | 81 | 179 | 146.5 | 187.five | a hundred thirty | 250 | a hundred and forty | 16 | sixty | 15 | M12*20(n=8) | 45° | fourteen | forty eight.8 | one hundred |

| one hundred fifty | 340 | 400 | 240 | one hundred forty five | fifty | a hundred and eighty | – | 185 | two hundred | 215 | 96 | 210 | 170 | 230 | one hundred fifty | 250 | 180 | 18 | 72.5 | 18 | M12*22(n=8) | 45° | fourteen | fifty three.eight | 120 |

Firm Profile

About CZPT Transmission:

We are a professional reducer company situated in HangZhou, ZHangZhoug province.

Our major merchandise is full range of RV571-a hundred and fifty worm reducers , also equipped GKM hypoid CZPT cal gearbox, GRC inline CZPT cal gearbox, Personal computer units, UDL Variators and AC CZPT s, G3 CZPT cal gear motor.

Products are widely used for apps this kind of as: foodstuffs, ceramics, packing, chemical substances, pharmacy, plastics, paper-creating, construction machinery, metallurgic mine, environmental protection CZPT , and all sorts of automatic lines, and assembly lines.

With CZPT shipping and delivery, exceptional right after-product sales service, CZPT d generating facility, CZPT goods market well both at residence and abroad. We have exported CZPT reducers to CZPT Asia, CZPT ern CZPT pe and Middle CZPT and so on.Our purpose is to create and innovate on basis of high high quality, and generate a good track record for reducers.

Packing data:Plastic Baggage+Cartons+Picket Cases , or on request

We participate Germany Hannver Exhibition-ZheJiang PTC Honest-Turkey Earn Eurasia

Logistics

Right after Sales Provider

one.Maintenance Time and Guarantee:Inside 1 calendar year right after receiving products.

two.Other Support: Such as modeling selection manual, installation guide, and problem resolution guidebook, etc.

FAQ

1.Q:Can you make as per CZPT er drawing?

A: Sure, we offer CZPT ized service for CZPT ers accordingly. We can use CZPT er’s nameplate for gearboxes.

two.Q:What is your terms of payment ?

A: 30% deposit prior to generation,stability T/T just before delivery.

3.Q:Are you a trading firm or company?

A:We are a manufacurer with CZPT d tools and knowledgeable staff.

4.Q:What is actually your generation potential?

A:8000-9000 PCS/Month

five.Q:Free of charge sample is CZPT or not?

A:Of course, we can supply free sample if CZPT er concur to pay for the courier price

6.Q:Do you have any certificate?

A:Sure, we have CE certificate and SGS certificate report.

Get in touch with data:

Ms Lingel Pan

For any questions just really feel free ton contact me. Many thanks for your variety attention to CZPT business!

Polyphase motors can be both two-stage or 3-phase motors. They perform like solitary-section induction motors, but each single-section and polyphase motors function on a rotating magnetic subject. Their rotating magnetic fields are created by two- or a few-section currents passing by way of two or more sets of coils. The rotating magnetic area generates torque. Polyphase motors are utilised in applications that call for substantial energy, these kinds of as the electrical power drive of compressors, hydraulic pumps, air conditioning compressors, and irrigation pumps.

china shop Industrial Transmission Drive RV Series Nmrv Reduction Gear Box Stainless Steel Worm Gearbox Speed Reducer manufacturers

Solution Description

Industrial Transmission CZPT Rv Series nmrv Reduction Equipment Box CZPT Metal Worm Gearbox CZPT Reducer

Goods Attributes

one. Produced of high-high quality aluminum alloy,mild bodyweight and CZPT -rusting

2. Massive output torque

three. Sleek in working and low in sound,can work CZPT time in dreadful circumstances.

four. CZPT in radiating efficiency.

five. CZPT -hunting in visual appeal,durable in service lifestyle and tiny in volume.

6. Suited for omnibearing installation.

Attributes of Worm Reducer /Gearbox

1.Widespread mounting dimensions.

two.Aluminum and solid iron housing.

three.Worm and worm wheel transmission.

four.Compact framework and light-bodyweight.

5.Wide variety of accessories.

Advantages of Worm Gearbox / Reducer

1.Exclusive housing layout will distinguish you from other rivals.