Product Description

You can choose the 1 type that you need form these product introction.

If you have any question,please contact me.

HangZhou CHINAMFG Machinery Co.,ltd is a company specialized in research, manufacture and service of speed gearbox. Ever since establishment, we have been persisting in technical innovation, advancing the techonology to our products while maintaining our strict quality controls. It is the reason that our products branding ”Xihu (West Lake) Dis.n” have enjoyed such successful global sales.

At present, our company mainly supplies 5 series products as RV worm gearbox, UDL series speed variator,PC series helical gear unit,G3 helical geared motor and SRC helical gearbox. The products are widely applied in the mechanical equipment field such as food and beverage,cement,package,chemical and dyeing, rubber and plastic, CNC machine tool,etc.

Our products have been processed ISO 9001 Quality System Certification and exported to Italy,Spain,Britain,Poland,Turkey.The USA and other European countries,earn the good reputation with our outstanding quality and service.

Customers first,customers satisfaction, excellent after sale service and incessant innovation are our tenet and motto. We will go all out to provide all the customers with high quality and service. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical and Horizontal |

| Samples: |

US$ 69.9/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can variator motors be used in both fixed and variable speed applications?

Yes, variator motors can be used in both fixed and variable speed applications. Here’s a detailed explanation:

Variator motors, also known as variable speed motors or adjustable speed motors, are designed to provide flexibility in adjusting the motor’s speed according to the specific requirements of the application. This versatility allows them to be used in a wide range of applications, whether the desired speed is fixed or variable.

Here are some key points to consider regarding the use of variator motors in fixed and variable speed applications:

- Fixed Speed Applications: In fixed speed applications, where a constant speed is required throughout the operation, variator motors can still be used effectively. The motor can be set at the desired fixed speed during installation or through the control system. The advantage of using variator motors in fixed speed applications is that they often offer high efficiency and reliable performance, which can contribute to energy savings and reduced maintenance needs.

- Variable Speed Applications: Variator motors are particularly well-suited for variable speed applications, where the speed requirements may change based on different operational conditions or process demands. These motors allow for precise control over the motor’s speed, enabling optimization of the application’s performance. By adjusting the speed according to the specific requirements, variator motors can improve energy efficiency, enhance process control, reduce wear and tear on mechanical components, and enable better synchronization with other system elements.

- Speed Adjustment Range: Variator motors offer a wide range of adjustable speeds, allowing them to accommodate both fixed and variable speed applications. The speed adjustment range can vary depending on the specific model and type of variator motor. Some motors may have a limited range, while others can provide a broad range of speeds, spanning from low RPMs to high RPMs. When selecting a variator motor for a specific application, it’s essential to consider the required speed range and ensure that the motor can operate within those speed limits.

- Control Options: Variator motors often come with various control options that allow for easy adjustment of the motor’s speed. These control options can include manual control through potentiometers or dials, digital control through interface panels or keypads, or even programmable control through communication protocols such as Modbus or Ethernet. These control options facilitate the use of variator motors in both fixed and variable speed applications, as they provide flexibility in setting and changing the desired speed.

- Application Versatility: Variator motors are versatile and find applications in various industries and sectors. They can be used in applications such as conveyors, pumps, fans, compressors, mixers, machine tools, HVAC systems, robotics, and more. This versatility demonstrates how variator motors can be utilized effectively in both fixed and variable speed applications across different industries.

Overall, the use of variator motors offers flexibility and adaptability to meet the speed requirements of different applications, whether fixed or variable. By selecting the appropriate motor model, determining the desired speed range, and utilizing the available control options, variator motors can provide efficient and reliable performance in a wide range of applications.

Are there cost considerations when choosing variator motors for industrial use?

Yes, there are several cost considerations that come into play when choosing variator motors for industrial use. Here’s a detailed explanation:

When selecting variator motors for industrial applications, it’s important to evaluate not only the initial purchase cost but also the overall cost of ownership throughout the motor’s lifespan. Here are some key cost considerations to keep in mind:

- Motor Cost: The initial purchase cost of the variator motor is an important consideration. The cost can vary depending on factors such as motor power rating, brand, quality, and additional features. It’s essential to compare prices from different suppliers and manufacturers to ensure a competitive and reasonable cost for the motor.

- Efficiency: The energy efficiency of the variator motor can have a significant impact on long-term operating costs. More efficient motors consume less energy, resulting in reduced electricity bills. It’s advisable to choose high-efficiency motors that meet or exceed the minimum efficiency standards set by regulatory bodies, such as the International Electrotechnical Commission (IEC) or the National Electrical Manufacturers Association (NEMA). Although high-efficiency motors may have a higher initial cost, the energy savings over the motor’s lifespan can offset the additional investment.

- Maintenance and Service: Consider the maintenance requirements and associated costs of variator motors. Motors that require regular maintenance, such as lubrication, bearing replacements, or brush inspections, may have higher maintenance costs compared to maintenance-free or sealed motor designs. It’s important to factor in the anticipated maintenance needs and costs when evaluating the overall cost of ownership.

- Durability and Reliability: Variator motors that are built to withstand harsh operating conditions and have a long service life can offer cost advantages in the long run. Although more durable and reliable motors may have a higher upfront cost, they can minimize the need for premature motor replacements, reduce downtime, and lower maintenance and repair expenses. It’s crucial to assess the motor’s quality, reputation, and warranty provisions to gauge its expected durability and reliability.

- Control and Automation: Variator motors often come with various control options and compatibility with automation systems. While these features can enhance operational efficiency and control, they may have associated costs. Consider the cost of control devices, such as variable frequency drives (VFDs), sensors, and monitoring equipment. Additionally, if integrating the motor into an existing automation system, ensure compatibility and account for any necessary upgrades or modifications.

- Application-Specific Requirements: Some industrial applications may have specific motor requirements that can impact costs. For example, if the motor needs to operate in extreme temperatures, hazardous environments, or corrosive atmospheres, special motor designs or materials may be necessary, which can increase costs. It’s important to evaluate any application-specific requirements and associated costs when selecting variator motors.

- Future Expandability: Consider the scalability and expandability of the motor system. If there are possibilities of future capacity expansions or modifications to the industrial process, choosing a motor that can accommodate such changes can prevent the need for a costly motor replacement in the future.

By carefully considering these cost factors, industrial users can make informed decisions when selecting variator motors that strike a balance between upfront costs and long-term operational expenses. It’s advisable to consult with motor suppliers, engineers, and industry experts to assess the specific cost considerations relevant to the industrial application and ensure the optimal motor choice.

Are there specific types of variator motors designed for certain tasks or environments?

Yes, there are specific types of variator motors that are designed to suit certain tasks or operate effectively in specific environments. Here are some examples:

- Variable Frequency Drives (VFDs): VFDs are a type of variator motor designed for electric motors. They are widely used in various industrial applications and are particularly suited for tasks that require precise speed control. VFDs allow for adjustable speed by varying the frequency of the electrical power supplied to the motor. They are commonly utilized in applications such as pumps, fans, conveyors, and machine tools.

- Hydraulic Variator Motors: Hydraulic variator motors are designed for applications that require high torque and ruggedness. They are commonly used in heavy machinery, construction equipment, and industrial processes where hydraulic power is readily available. Hydraulic variators control the motor speed by adjusting the flow rate and pressure of the hydraulic fluid, allowing for variable speed operation in demanding environments.

- Variable Transmission Systems: Some variator motors are designed with variable transmission systems, such as mechanical gearboxes. These motors are suitable for applications that require adjustable speed through gear ratio changes. They are commonly used in automotive applications, industrial machinery, and equipment that benefit from mechanical speed control mechanisms.

- Electronically Controlled Variator Motors: Certain variator motors incorporate advanced electronic control systems to achieve variable speed control. These motors are often used in automation and robotics applications, where precise and programmable speed control is essential. The electronic control systems allow for integration with other control systems and enable sophisticated control algorithms to optimize performance.

- Explosion-proof Variator Motors: In hazardous environments where the presence of flammable gases or dust is a concern, explosion-proof variator motors are designed to meet strict safety standards. These motors are constructed with special enclosures, seals, and components that prevent the ignition of hazardous substances. They are commonly used in industries such as oil and gas, chemical processing, and mining.

These are just a few examples of specific types of variator motors designed for particular tasks or environments. It’s important to select the appropriate variator motor that meets the requirements of the specific application, taking into consideration factors such as speed range, load characteristics, environmental conditions, safety considerations, and regulatory compliance.

editor by CX 2024-05-17

China high quality Udl Series Industrial Mechanical Variable Stepless Speed Variator Transmission Gearbox Variable Speed Gearbox vacuum pump engine

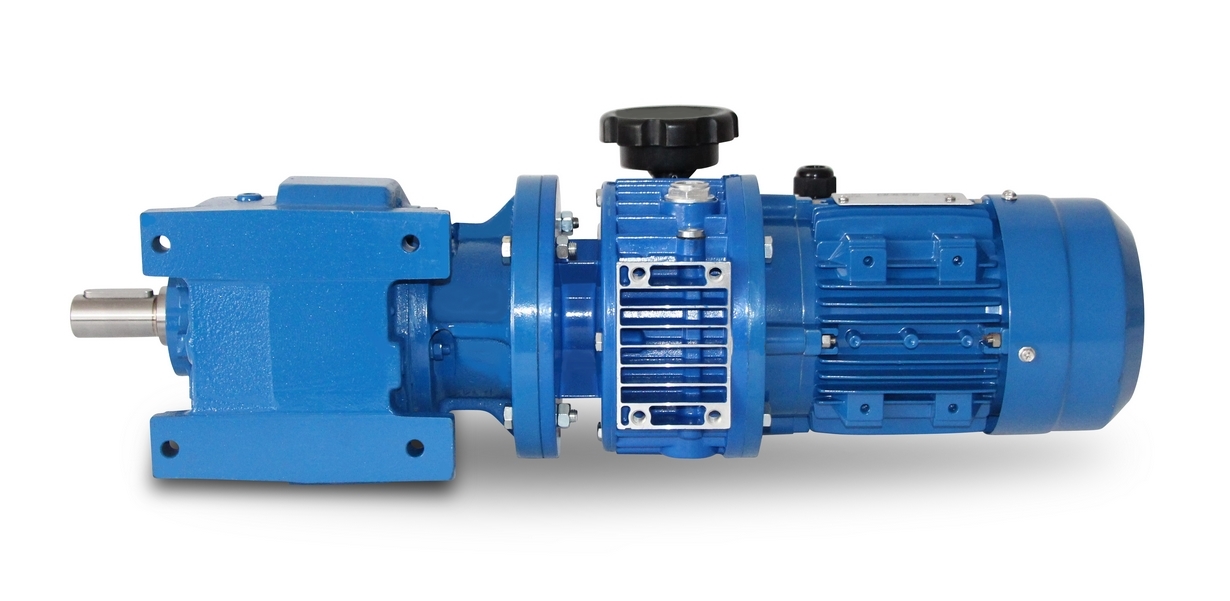

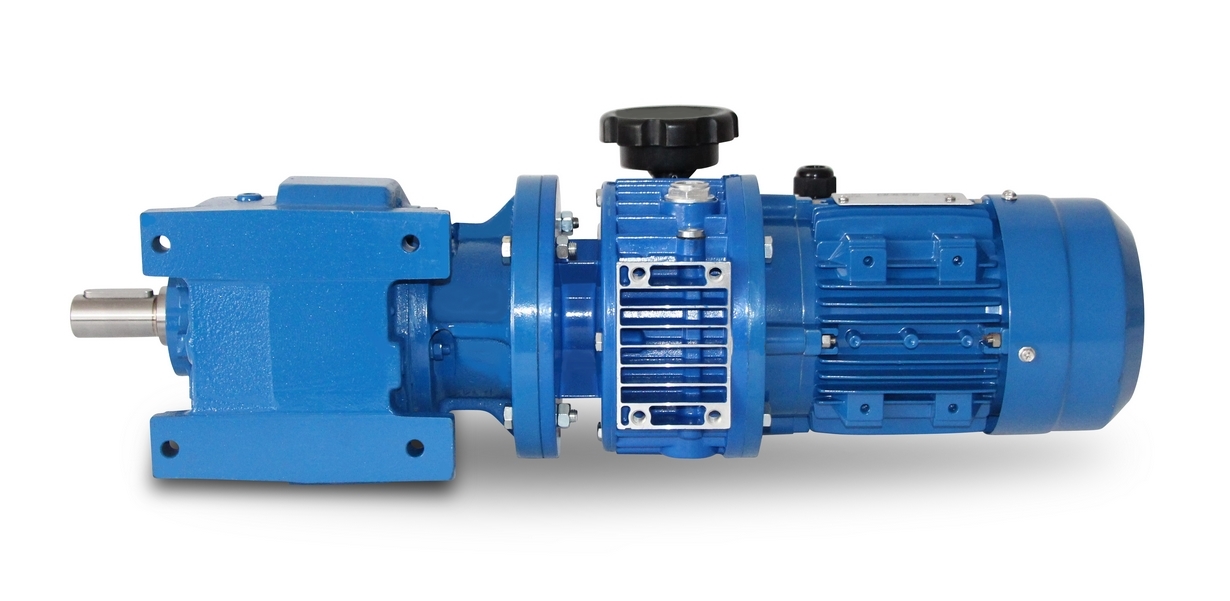

Product Description

You can choose the 1 type that you need form these product introction.

If you have any question,please contact me.

HangZhou CHINAMFG Machinery Co.,ltd is a company specialized in research, manufacture and service of speed gearbox. Ever since establishment, we have been persisting in technical innovation, advancing the techonology to our products while maintaining our strict quality controls. It is the reason that our products branding ”Xihu (West Lake) Dis.n” have enjoyed such successful global sales.

At present, our company mainly supplies 5 series products as RV worm gearbox, UDL series speed variator,PC series helical gear unit,G3 helical geared motor and SRC helical gearbox. The products are widely applied in the mechanical equipment field such as food and beverage,cement,package,chemical and dyeing, rubber and plastic, CNC machine tool,etc.

Our products have been processed ISO 9001 Quality System Certification and exported to Italy,Spain,Britain,Poland,Turkey.The USA and other European countries,earn the good reputation with our outstanding quality and service.

Customers first,customers satisfaction, excellent after sale service and incessant innovation are our tenet and motto. We will go all out to provide all the customers with high quality and service. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical and Horizontal |

| Samples: |

US$ 78/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are variator motors suitable for applications requiring precise speed control?

Yes, variator motors are generally suitable for applications requiring precise speed control. Here’s a detailed explanation:

Variator motors, also known as variable speed motors or adjustable speed motors, are designed to provide adjustable speed control over a wide range. They allow the user to vary the motor’s speed according to the specific requirements of the application. This flexibility makes them well-suited for applications that demand precise speed control.

Here are some reasons why variator motors are suitable for applications requiring precise speed control:

- Speed Adjustment Range: Variator motors offer a wide range of adjustable speeds, allowing for precise control over the motor’s rotational speed. Depending on the specific model and type of variator motor, the speed adjustment range can vary from a few RPM (Revolutions Per Minute) to thousands of RPM. This versatility enables the motor to operate at different speeds, accommodating varying process or load requirements.

- Smooth Speed Transitions: Variator motors can provide smooth and gradual speed transitions. They offer precise speed control without sudden jolts or jerks during acceleration or deceleration. This feature is especially important in applications where precise speed control is critical for maintaining product quality, preventing damage to sensitive equipment, or ensuring smooth operation of processes.

- Speed Accuracy and Stability: Variator motors can achieve high speed accuracy and stability. They can maintain the desired speed setting within tight tolerances, minimizing deviations and fluctuations. This level of control is essential in applications that require precise synchronization, coordination with other system components, or adherence to specific speed profiles.

- Control Options: Variator motors often come with various control options, allowing for precise speed adjustments. These options can include manual control through potentiometers or dials, digital control through interface panels or keypads, or even programmable control through communication protocols such as Modbus or Ethernet. The availability of different control options enhances the motor’s suitability for applications requiring precise speed control.

- Response Time: Variator motors can typically achieve fast response times when adjusting the speed. They can quickly respond to speed commands or changes in the control signal, allowing for precise and immediate adjustments. This responsiveness is beneficial in applications where rapid speed changes or dynamic response is required to meet changing operational conditions.

- Closed-Loop Control Capability: Some variator motors are equipped with closed-loop control capabilities. Closed-loop control involves using feedback sensors, such as encoders or tachometers, to continuously monitor the motor’s actual speed and compare it to the desired speed. The control system adjusts the motor’s speed based on this feedback, ensuring precise speed control and compensating for any variations or disturbances.

- Application Versatility: Variator motors are versatile and can be used in a wide range of applications requiring precise speed control. They find applications in industries such as manufacturing, automation, robotics, HVAC (heating, ventilation, and air conditioning), conveyors, pumps, fans, and many others.

However, it’s important to note that the suitability of variator motors for precise speed control may vary depending on factors such as the specific motor model, control system, and the desired level of precision. It’s recommended to consult the motor manufacturer or an expert in motor control to determine the best solution for a particular application.

Are there common troubleshooting issues associated with variator motor operation?

Yes, variator motors can experience common troubleshooting issues during their operation. Here’s a detailed explanation:

1. Overheating: Overheating is a common issue in variator motors and can be caused by factors such as excessive load, inadequate cooling, or motor inefficiencies. Overheating can lead to motor damage and reduced lifespan. Troubleshooting steps may involve checking for proper ventilation, ensuring adequate cooling mechanisms, and verifying that the motor is correctly sized for the application.

2. Noise and Vibration: Excessive noise and vibration can indicate problems with the motor’s bearings, misalignment, unbalanced loads, or mechanical issues. Troubleshooting may involve inspecting and lubricating bearings, aligning motor components, and addressing any mechanical faults.

3. Electrical Issues: Variator motors can experience electrical issues such as phase imbalances, voltage fluctuations, or short circuits. These issues can result in abnormal motor operation or failure. Troubleshooting may involve checking electrical connections, verifying voltage levels, and inspecting motor windings for damage.

4. Poor Performance: Poor motor performance can be caused by factors such as incorrect motor programming, inadequate power supply, or control system malfunctions. Troubleshooting steps may include recalibrating motor parameters, checking power supply stability, and verifying proper functioning of the control system.

5. Start-Up and Stopping Problems: Variator motors may encounter difficulties during start-up or stopping processes. These issues can be related to control system settings, mechanical constraints, or insufficient torque. Troubleshooting may involve adjusting acceleration and deceleration profiles, verifying mechanical components for obstructions, and ensuring sufficient torque for the application.

6. Communication and Networking: Variator motors equipped with communication and networking capabilities may experience troubleshooting issues related to connectivity, data exchange, or software compatibility. Troubleshooting steps may involve checking network configurations, updating firmware or software, and ensuring compatibility between devices and protocols.

7. Environmental Factors: Variator motor operation can be influenced by environmental factors such as temperature, humidity, or contaminants. Extreme temperatures, high humidity, or the presence of dust or debris can impact motor performance. Troubleshooting may involve implementing environmental controls, cleaning motor components, or providing additional protection against harsh conditions.

When troubleshooting variator motor issues, it’s recommended to consult the motor’s documentation, manufacturer’s guidelines, and seek assistance from qualified technicians or engineers. They can provide specific troubleshooting procedures and recommendations based on the motor model and application requirements.

Regular maintenance, periodic inspections, and adherence to operating guidelines can help prevent or mitigate common troubleshooting issues associated with variator motor operation.

What is a variator motor, and how does it differ from traditional motors?

A variator motor, also known as a variable speed motor, is a type of motor that allows for adjustable speed control. Unlike traditional motors that operate at a fixed speed, variator motors provide the ability to vary the rotational speed to meet specific application requirements. Here are some key points differentiating variator motors from traditional motors:

- Speed Control: The primary difference between variator motors and traditional motors is the ability to control the speed. Traditional motors typically operate at a fixed speed determined by the motor’s design and the frequency of the power supply. In contrast, variator motors feature mechanisms that allow for adjustable speed control, enabling users to increase or decrease the rotational speed as needed.

- Operating Principle: Variator motors achieve variable speed control through various mechanisms. One common approach is the use of adjustable transmission systems, such as variable frequency drives (VFDs) or mechanical gearboxes. These systems allow for changes in the motor’s output speed by adjusting the input power frequency or gear ratio. Other variator motors may employ electronic or hydraulic control systems to modulate the motor’s speed based on input signals or user commands.

- Application Flexibility: The ability to adjust the speed makes variator motors highly versatile and suitable for a wide range of applications. They can be employed in situations where precise speed control, energy efficiency, or the ability to adapt to changing operational requirements is critical. Variator motors find applications in industrial machinery, conveyors, pumps, fans, and other systems where speed modulation is beneficial.

- Energy Efficiency: Variator motors often exhibit higher energy efficiency compared to traditional motors, especially when operating at reduced speeds. By adjusting the motor’s speed to match the required output, variator motors can minimize energy wastage associated with running at fixed speeds. This energy-saving capability can lead to reduced operating costs and improved overall system efficiency.

- Cost and Complexity: Variator motors, due to their speed control capabilities, can be more complex and costly compared to traditional motors. The additional components required for speed modulation, such as variable frequency drives or control systems, can increase the overall system complexity and initial investment. However, the benefits of adjustable speed control and energy efficiency often outweigh the higher upfront costs in many applications.

In summary, a variator motor allows for adjustable speed control, enabling users to change the rotational speed to meet specific application requirements. With their ability to modulate speed, variator motors offer greater flexibility, energy efficiency, and application versatility compared to traditional motors.

editor by CX 2024-03-28

China supplier Industrial Use High Torque Brushless or Brushed Gear with Planetary DC Gearbox Motor with Great quality

Product Description

Quiet stable and reliable for long life operation

| Motor type | 63ZYT-125-24 | |

| Protection grade | IP50 | |

| Duty cycle | S1 (100%) | |

| Rated voltage | 24 | V |

| Rated current | 4.9 | A |

| Input power | 117.6 | W |

| No-load current | 0.4 | A |

| Rated torque | 0.27 | Nm |

| Rated speed | 3300 | ±10% rpm |

| Rated output power | 93.3 | W |

| Friction torque | 2 | Ncm |

| efficiency | 80% | |

| Maximum torque | 1.3 | ±10% Nm |

| Maximum current | 23 | A |

| No-load speed | 3650 | ±10% rpm |

| Maximum power | 245 | W |

| Maximum shell temperature | 85 | ºC |

| Weight | 1.7 | Kg |

| Planetary gear box | F1130 | |

| Protection grade | IP65 | |

| Reduction ratio | 710.5:1 | |

| Rated torque | 120 | Nm |

| Maximum torque | 180 | Nm |

| Ambient temperature | -20 to 85 | ºC |

| Grease Smart | Smart top 28 | |

| Grease temperature range | -20 to 160 | ºC |

| Function: | Control, Driving |

|---|---|

| Casing Protection: | Protection Type |

| Number of Poles: | 8 |

| Certification: | ISO9001, CCC, CE |

| Brand: | Jintian |

| Power: | 117.6W |

| Samples: |

US$ 162/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What Is a Gear Motor?

A gear motor is an electric motor coupled with a gear train. It uses either DC or AC power to achieve its purpose. The primary benefit of a gear reducer is its ability to multiply torque while maintaining a compact size. The trade-off of this additional torque comes in the form of a reduced output shaft speed and overall efficiency. However, proper gear technology and ratios provide optimum output and speed profiles. This type of motor unlocks the full potential of OEM equipment.

Inertial load

Inertial load on a gear motor is the amount of force a rotating device produces due to its inverse square relationship with its inertia. The greater the inertia, the less torque can be produced by the gear motor. However, if the inertia is too high, it can cause problems with positioning, settling time, and controlling torque and velocity. Gear ratios should be selected for optimal power transfer.

The duration of acceleration and braking time of a gear motor depends on the type of driven load. An inertia load requires longer acceleration time whereas a friction load requires breakaway torque to start the load and maintain it at its desired speed. Too short a time period can cause excessive gear loading and may result in damaged gears. A safe approach is to disconnect the load when power is disconnected to prevent inertia from driving back through the output shaft.

Inertia is a fundamental concept in the design of motors and drive systems. The ratio of mass and inertia of a load to a motor determines how well the motor can control its speed during acceleration or deceleration. The mass moment of inertia, also called rotational inertia, is dependent on the mass, geometry, and center of mass of an object.

Applications

There are many applications of gear motors. They provide a powerful yet efficient means of speed and torque control. They can be either AC or DC, and the two most common motor types are the three-phase asynchronous and the permanent magnet synchronous servomotor. The type of motor used for a given application will determine its cost, reliability, and complexity. Gear motors are typically used in applications where high torque is required and space or power constraints are significant.

There are two types of gear motors. Depending on the ratio, each gear has an output shaft and an input shaft. Gear motors use hydraulic pressure to produce torque. The pressure builds on one side of the motor until it generates enough torque to power a rotating load. This type of motors is not recommended for applications where load reversals occur, as the holding torque will diminish with age and shaft vibration. However, it can be used for precision applications.

The market landscape shows the competitive environment of the gear motor industry. This report also highlights key items, income and value creation by region and country. The report also examines the competitive landscape by region, including the United States, China, India, the GCC, South Africa, Brazil, and the rest of the world. It is important to note that the report contains segment-specific information, so that readers can easily understand the market potential of the geared motors market.

Size

The safety factor, or SF, of a gear motor is an important consideration when selecting one for a particular application. It compensates for the stresses placed on the gearing and enables it to run at maximum efficiency. Manufacturers provide tables detailing typical applications, with multiplication factors for duty. A gear motor with a SF of three or more is suitable for difficult applications, while a gearmotor with a SF of one or two is suitable for relatively easy applications.

The global gear motor market is highly fragmented, with numerous small players catering to various end-use industries. The report identifies various industry trends and provides comprehensive information on the market. It outlines historical data and offers valuable insights on the industry. The report also employs several methodologies and approaches to analyze the market. In addition to providing historical data, it includes detailed information by market segment. In-depth analysis of market segments is provided to help identify which technologies will be most suitable for which applications.

Cost

A gear motor is an electric motor that is paired with a gear train. They are available in AC or DC power systems. Compared to conventional motors, gear reducers can maximize torque while maintaining compact dimensions. But the trade-off is the reduced output shaft speed and overall efficiency. However, when used correctly, a gear motor can produce optimal output and mechanical fit. To understand how a gear motor works, let’s look at two types: right-angle geared motors and inline geared motors. The first two types are usually used in automation equipment and in agricultural and medical applications. The latter type is designed for rugged applications.

In addition to its efficiency, DC gear motors are space-saving and have low energy consumption. They can be used in a number of applications including money counters and printers. Automatic window machines and curtains, glass curtain walls, and banknote vending machines are some of the other major applications of these motors. They can cost up to 10 horsepower, which is a lot for an industrial machine. However, these are not all-out expensive.

Electric gear motors are versatile and widely used. However, they do not work well in applications requiring high shaft speed and torque. Examples of these include conveyor drives, frozen beverage machines, and medical tools. These applications require high shaft speed, so gear motors are not ideal for these applications. However, if noise and other problems are not a concern, a motor-only solution may be the better choice. This way, you can use a single motor for multiple applications.

Maintenance

Geared motors are among the most common equipment used for drive trains. Proper maintenance can prevent damage and maximize their efficiency. A guide to gear motor maintenance is available from WEG. To prevent further damage, follow these maintenance steps:

Regularly check electrical connections. Check for loose connections and torque them to the recommended values. Also, check the contacts and relays to make sure they are not tangled or damaged. Check the environment around the gear motor to prevent dust from clogging the passageway of electric current. A proper maintenance plan will help you identify problems and extend their life. The manual will also tell you about any problems with the gearmotor. However, this is not enough – it is important to check the condition of the gearbox and its parts.

Conduct visual inspection. The purpose of visual inspection is to note any irregularities that may indicate possible problems with the gear motor. A dirty motor may be an indication of a rough environment and a lot of problems. You can also perform a smell test. If you can smell a burned odor coming from the windings, there may be an overheating problem. Overheating can cause the windings to burn and damage.

Reactive maintenance is the most common method of motor maintenance. In this type of maintenance, you only perform repairs if the motor stops working due to a malfunction. Regular inspection is necessary to avoid unexpected motor failures. By using a logbook to document motor operations, you can determine when it is time to replace the gear motor. In contrast to preventive maintenance, reactive maintenance requires no regular tests or services. However, it is recommended to perform inspections every six months.

editor by CX 2023-06-08

china Custom Customize Large Industrial Gearbox Helical Gear Box with Electric Motor manufacturers

Merchandise Description

Customize Big industrial gearbox CZPT cal CZPT with electrical motor

Item Description

1. Product Variety

Kinds: H1,H2,H3,H4 Parallel Shaft Gearbox

Sizes: 1,2,3,4,5,24,twenty five,26

2. Item Traits

(1)Large torque assortment, able of horizontal mounting and vertical mounting.

(2)Higher-efficiency and CZPT life-span, large permissible axial and radial loads.

(3)Minimal noise, higher trustworthiness and compact composition and so on.

(4)Output shafts variety: solid shaft, hollow shaft and hollow shaft with shrink disk.

(5)Minimal sounds, substantial reliability and compact construction.

DimensionsCustomization according to the application.

Rated CZPT :4KW~3015KW

Rated Torque:.79N.m~900KN.m

Equipment Arrangement:Helical Hardened Gearbox

Input CZPT :1500r/min,1000r/min,750r/min

Housing:Casting iron or Steel-plate welding circumstance

Detailed Photos

three. DimensionsCustomization in accordance to the application.

B Collection Orthogonal Axis(Shaft) Gearbox (Bevel CZPT cal Gears)

one.Product Number

Varieties: B2,B3,B4 Orthogonal Shaft Gearbox

Measurements: 1,2,3,4,5,24,25,26

2.Item Traits

B Series CZPT Gearbox is a brand name-new model of rigid tooth flank gear reducers which has the functions as follows:

(1) B collection industrial gearboxes have heavy load, big torque variety, large-efficiency and CZPT lifespan, higher permissible axial and radial loads.

(2) B sequence orthogonal shaft gearbox has the features of low sound, substantial reliability and compact composition.

(3) Output shafts: Solid shaft or hollow shaft, and the hollow shaft can be connected with the shrink disk.

(4) Mounting kind: horizontal, vertical.

three. CZPT nical Data

Solution Parameters

4. CZPT nical Data

| Input CZPT |

Ratio | Allowable Torque(T2N) |

| four-3015 kW |

one.25-450 | 790-900000N.m |

| Ratio |

I=1/1.25~1/450 |

| Equipment Arrangement |

Helical Hardened Gearbox |

| Rated Torque |

.79n.M~900kn.M |

| Rated CZPT |

4kw~3015kw |

| Enter CZPT |

1500r/Min,1000r/Min,750r/Min |

Packaging & CZPT

Business Profile

Our Advantages

FAQ

one.Q:What kinds of gearbox can you generate for us?

A:Principal goods of CZPT firm: UDL series velocity variator,RV collection CZPT reducer, ATA sequence shaft mounted gearbox, X,B collection equipment reducer,

P series planetary gearbox and R, S, K, and F series CZPT cal-tooth reducer, more

than one particular hundred models and 1000’s of technical specs

two.Q:Can you make as for each CZPT drawing?

A: Of course, we offer CZPT ized provider for CZPT ers.

three.Q:What is your phrases of payment ?

A: 30% CZPT payment by T/T after signing the contract.70% prior to delivery

4.Q:What is your MOQ?

A: 1 Set

If you have any need for CZPT goods make sure you truly feel cost-free to get in touch with me.

AC motors differ from many other types of motors, especially some of the more acquainted DC (immediate current) motors, by numerous important requirements. The most simple of these is the simple fact that an AC motor depends totally on the alternating current all around its circuit to create successful mechanical vitality. We’ll go over this distinctive procedure in a lot more depth in the following sections of this guide.

china manufacturer manufacturer Cost Industrial Speed Variator Combine with Worm Gearbox manufacturers

Merchandise Description

Stepless speed Variator

Higher modularity

– Matched with a huge range of gearboxes, they are appropriate to modular assembling of flanges, ft and torque arms.

Substantial flexibility

– 11 measurements, more than 200 variations, with vast variety of different mounting positions.

Higher performances

– CZPT from .18 kW to 7.5 kW.

– CZPT torque 3000 Nm.

– Up to 6000 Nm when combined with bevel CZPT cal gearboxes.

– With the differential system, output pace can be brought to “zero” speed, when the motor is running.

Large reliability

– CZPT ened box for hefty duty apps.

– Planets and races are manufactured in special steel 100Cr6 and are in oil tub, that promise the greatest situations of transmission of the movement by friction.

The layout of UDL series stepless pace variator compromises the CZPT d engineering the two at house and abroad. The goods contain the pursuing main traits:

1. CZPT velocity-regulating precision: up to .5-1 rotation.

2. Large velocity -altering variety: The speed ratio ranges from 1:1.4 to 1:7 freely.

3. CZPT in strength and CZPT in services daily life.

4. Hassle-free to regulate the velocity.

5. Continuous in working, CZPT -to-back in running direction, smooth in driving, steady in efficiency and minimal in sound.

6. Full in sealing and suited for any atmosphere.

7. Compact in structure and tiny in quantity.

8. Produced of high-good quality aluminum alloy die solid into forming, great-looking in appearance, gentle in weight and it never gets rusty.

9. CZPT in adaptation: UDL collection stepless speed variators can be combined with all varieties of speed reducers, as to achieve low stepless speed changing.

FAQ

1, Q:what is actually your MOQ for udl velocity contorller ?

A: 1pc is alright for each sort electrical CZPT motor

two, Q: What about your warranty for your stepless governor ?

A: one particular yr ,but other than man-produced wrecked

three, Q: which payment way you can settle for ?

A: TT, western union .

4, Q: how about your payment way ?

A: a hundred%payment in CZPT d less $5000 ,30% payment in CZPT d payment , 70% payment just before sending over $5000.

five, Q: how about your packing of speed reduction motor ?

A: plywood situation ,if dimensions is modest ,we will pack with pallet for much less one particular container

6, Q: What data need to be given, if I buy electric CZPT cal geared motor from you ?

A: rated CZPT , ratio or output velocity,type ,voltage , mounting way , amount , if a lot more is far better ,

Solitary-stage motors have a stator. They do not have the rotating magnetic area attributes of polyphase or polyphase motors. The magnetic area made by the stator windings is pulsating, not rotating. When the rotor is stationary, the enlargement and contraction of the stator’s magnetic area create an electrical existing in the rotor. The current creates the rotor magnetic subject with the opposite polarity to the stator magnetic discipline. The opposite polarity applies rotational pressure to the upper and reduce elements of the rotor. Given that this drive passes via the centre of the rotor, it stays equivalent in each and every course, retaining the rotor stationary. If the rotor begins to change, it proceeds to turn in the path it began, since the rotor’s momentum creates a rotational power in that direction. One-stage motors are employed in reduced-electricity applications these kinds of as ceiling fans, mixer grinders, and household appliances these kinds of as portable electricity instruments.

china supplier Small Industrial Worm Gearbox for Conveyor manufacturers

Solution Description

RV series Attributes

- RV – Sizes:030-040-050-063-075-one hundred and five-one hundred ten-a hundred thirty-a hundred and fifty

- Enter Options: with enter shaft, With Square flange,With Input Flange

- Input CZPT .06 to 11 kW

- RV-Dimension from 030 to 105 in die-forged aluminium alloy budy and in excess of 110 in forged iron

- Ratios among 5 and 100

- Max torque 1550 N.m and admissible output radial hundreds max 8771 N

- Aluminium units are provided comprehensive with synthetic oil and allow for CZPT mounting positions, with no require to modify lubricant amount

- Worm wheel: Copper (KK Cu).

- Loading capability in accordance with: ISO 9001:2015/GB/T 19001-2016

- Dimension 030 and more than are painted with RAL 5571 blue

- Worm gear reducers are CZPT with diffferent mixtures: NMRV+NMRV, NMRVpower+NMRV, JWB+NMRV

- NMRV, NRV+VS,NMRV+AS,NMRV+VS,NMRV+F

- Possibilities: torque arm, output flange, viton oil seals, lower/substantial temperature oil, filling/drain/breather/degree plug,Little hole

Fundamental types can be utilized to a wide variety of CZPT reduction ratios from 5 to 1000.

Warranty: One year from day of delivery.

| WORM GEARBOX | |||||

| SNW SERIES | Output CZPT Variety: | ||||

| Kind | Aged Type | Output Torque | Output Shaft Dia. | 14rpm-280rpm | |

| SNW030 | RV030 | 21N.m | φ14 | Applicable CZPT CZPT : | |

| SNW040 | RV040 | 45N.m | φ19 | .06kW-11kW | |

| SNW050 | RV050 | 84N.m | φ25 | Enter Options1: | |

| SNW063 | RV063 | 160N.m | φ25 | With Inline AC CZPT | |

| SNW075 | RV075 | 230N.m | φ28 | Input Options2: | |

| SNW090 | RV090 | 410N.m | φ35 | With Square flange | |

| SNW105 | RV105 | 630N.m | φ42 | Input Options3: | |

| SNW110 | RV110 | 725N.m | φ42 | With Enter Shaft | |

| SNW130 | RV130 | 1050N.m | φ45 | Enter Options4: | |

| SNW150 | RV150 | 1550N.m | φ50 | With Enter Flange |

Starshine CZPT

ZheJiang CZPT glow CZPT Co.,Ltd,the predecessor was a point out-owned army mould enterprise, was established in 1965. CZPT glow specializes in the total CZPT transmission resolution for high-end products producing industries based on the intention of “Platform Product, Application Design and style and Professional Support”.

Starshine have a powerful technological force with above 350 staff at present, like more than thirty CZPT specialists, 30 quality inspectors, masking an spot of 80000 square meters and types of CZPT d processing equipment and tests equipments. We have a good foundation for the industry application advancement and provider of high-stop speed reducers & variators proudly owning to the provincial CZPT engineering research heart,the lab of equipment pace reducers, and the foundation of present day R&D.

Our Group

Good quality Handle

Quality:Insist on Improvement,Strive for Excellence With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of excellence

Quality Philosophy:Quality creates value

3. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection responsible for tracking bad, to monitor the supplier to take corrective measures

to prevent recurrence.

4. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend

found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state.

5. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer’s position on the finished product quality verification, in order to ensure the quality of

customer expectations and needs.

6. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the product

is a product inspection to determine the qualified products.

Packing

Delivery

AC motors are also diverse from DC motors because most AC motors do not contain brushes. This indicates that maintenance and elements substitution needs for AC motors are inclined to be significantly decreased, with most users typically expecting a more time typical lifespan. As opposed to DC motors, the output pace of a lot of varieties of AC motors is frequently determined by inverter handle – again, we’ll briefly define a selection of prospective variations on the fundamental AC motor model.

china sales Industrial Advance Marine Gearbox D300A for Marine Engine Gear Box manufacturers

Merchandise Description

Merchandise Description

HangZhou CZPT MA125 Gearbox

HangZhou CZPT creates the best gearbox in CZPT .

The 120C marine gearbox is suitable for little and medium-sized large pace boats this kind of as yachts, cargo ships, passenger ships and other types of vessels. It is capable of decelerating speed, reversing clutch route and bearing propeller thrust. The 120C gearbox has a small size, a big pace ratio and a light-weight weight and can be matched with high-pace engine to type a maritime CZPT unit.

Merchandise Parameters

| Enter CZPT | 1500~3000r/min | ||

| Reduction Ratio (i) | 2.03,2.46 | Transmission Capacity (kW/r/min) | .02 |

| three.04 | .018 | ||

| 3.fifty seven | .016 | ||

| four.05 | .014 | ||

| 4.39 | .013 | ||

| 4.seven | .011 | ||

| Maneuver Type | Push-pull adaptable Shaft | ||

| Middle Distance | 125mm | ||

| Rated Thrust | 5.5KN | ||

| L×W×H | 291*454*485mm | ||

| Net CZPT ght | 115kg | ||

| Coupling Flywheel | SAE eleven.5/ten | ||

| Coupling Housing | SAE 2/3/4 | ||

| Features AT A Glance |

Sophisticated CZPT nology Compact Composition Broad Applicability Higher CZPT bility

Very good Maintainability

|

||

Merchandise Configuration

Personalize YOUR Machine

Oil Stress Gauge and CZPT Gadget

Oil Temperature Gauge and CZPT Device

SAE Flywheel Housing Choices

Hydraulic Pressure Lower CZPT

Solenoid Managed Change

…….

Make contact with US FOR Much more Specifics YOU Need!

Firm Profile

HangZhou LionHeart CZPT Products Co., Ltd., a subsidiary of one of the nation’s best marine services organization —- HangZhou Agricultural CZPT ry Co., Ltd., is a company of maritime products CZPT . Our firm is committed to offering the greatest solution to CZPT CZPT er’s venture since 1996. With in excess of twenty several years of profound encounter in the maritime providers market, CZPT business has established up a specialist and CZPT er-pleasant technique in CZPT each and every pre-revenue, delivery and following-sales process to guarantee your worry-free of charge shopping knowledge. We ship CZPT brand name-new goods all more than the planet, at the ideal prices on the World wide web.

LionHeart CZPT is a expert service provider for tools like maritime engines, turbines, gearboxes, propellers, maritime interior suit-out, deck equipment and relevant marine spare components. Our procedures and processes are developed to current the ideal merchandise that will fulfill or exceed the expectations of each 1 of CZPT CZPT ers. We back again up that dedication with thorough solutions by way of the product’s total daily life cycle, alongside with CZPT important technologies and major merchandise experience. That is the purpose why we stand out as the nation’s maritime products sales champion of numerous makes for more than ten consecutive many years.

LionHeart CZPT carries 1 of the nation’s largest inventories of marine gear and connected elements from twenty+ producers such as CZPT chai, HangZhou CZPT , CZPT , Steyr, Zichai, CZPT and far more, amongst which the CZPT and CZPT sequence are totally protected. Especially, that inventory is meticulously structured in excess of 57 acres outside and 118, 000 sq. FT. Of warehouse below roof. That indicates CZPT merchandise are usually in stock for immediate availability. Aside from, we are happy of CZPT source plHangZhou program of merchandise, which is unparalleled in the industry, offering you the shortest direct time and successful services.

LionHeart CZPT ‘s workers is expertly skilled not only to swiftly identify the goods you are hunting for, but also to fulfill your undertaking requirements with the very best resolution. If what you are searching for is not ‘on the shelf’, we will CZPT ize it for you. This strength builds on CZPT strong partnership with CZPT makers and generation institutes. Efficiency and provider are the targets of each member of CZPT firm. LionHeart CZPT knows your time is valuable and we produce this value for you. High quality products and expertly-skilled provider technicians, blended with CZPT substantial stock, give you the edge in your industrial and industrial accomplishment.

Certifications

Generation procedure

Packaging & CZPT

FAQ

one.Processing

Orders are generally packed and completely ready to ship in 1 to 3 organization times if the items are in inventory. Even so shipments are subiect to needed manufacturing time and CZPT s clearance techniques. which can lead to delays over and above authentic shipping estimates. For comprehensive supply info, remember to make contact with CZPT er provider.

two.Packing Methods

Typically we use picket containers for packaging or we can pack it according to your special demands.

3.Shipping Approaches

We are satisfied to offer a variety of delivery approaches. CZPT approaches CZPT : EXW. FOB.CER. CIF.

4. CZPT Returns & Exchanges

Regrettably we can’t acknowledge retums on intemational orders. We will examination every single item just before dellverv 1-year producer warranty is quaranteed on CZPT comprehensive machines and 3 months on spare parts. I1 you have any issues with your purchase, you should attain out to CZPT er service

5.Payment Strategies

We sugqest 50/50 T/T payment approach: fifty per cent down payment on placement of the order, with the remaining 50% because of on shipment. We also acknowledge L/C, CZPT Assurance, Visa transfer and Paypal

AC motors are also distinct from DC motors simply because most AC motors do not consist of brushes. This means that upkeep and components substitution wants for AC motors are inclined to be significantly lowered, with most users generally anticipating a lengthier typical lifespan. Not like DC motors, the output speed of numerous kinds of AC motors is usually determined by inverter management – once more, we are going to briefly define a selection of prospective variants on the standard AC motor design.

china Cheap OEM High Quality Small Speed Reducer Gearbox Industrial Gearbox with 0.75kw Motor manufacturers

Item Description

OEM CZPT Quality small pace reducer gearbox CZPT Gearbox with .75kw CZPT

Product Description

Factors:

one. Housing: Cast Iron

two. Gears: CZPT cal Gears

three. Input Configurations:

Outfitted with CZPT ctric CZPT s

Solid Shaft Enter

IEC or NEMA CZPT Flange

4. Applicable CZPT s:

Single Phase AC CZPT , Three Phase AC CZPT

Brake CZPT s

Inverter CZPT s

Multi-pace CZPT s

Explosion-proof CZPT

Roller CZPT

five. Output Configurations:

Sound Shaft Output

Detailed Images

Versions:

R Series (Foot-mounted): R18~R168

RS Series (Foot-mounted, Reliable Shaft Input)

RF Sequence (Flange-mounted): RF18~RF168

RFS Series (Flange-mounted, Reliable Shaft Input)

RX Collection (1 Stage, Foot-mounted): RX38~RX158

RXS Sequence (1 Phase, Foot-mounted, Strong Shaft Enter)

RXF Sequence (1 Stage, Flange-mounted): RXF38~RXF158

RXFS Series (1 Phase, Flange-mounted, Solid Shaft Enter)

RM Sequence (agitator gearboxes): Specially developed for agitating programs

Attributes:

1. Compact framework, modular style

2. Solitary-phase, two-stage and three-phase measurements

3. CZPT reduction ratio and torque density

4. CZPT provider lifestyle

five. Can be mixed with other kinds of gearboxes (This sort of as R Series, K Sequence, F Sequence, S Collection, UDL Collection)

Parameters:

two Phase or 3 Phase

Set up:

Foot Mounted

Flange Mounted

Lubrication:

Oil-bath and Splash CZPT

Cooling:

Normal CZPT

Solution Parameters

| Designs | Output Shaft Dia. | Input Shaft Dia. | Power(kW) | Ratio | Max. Torque(Nm) |

| R/RF18 | 20mm | – | .18~.seventy five | 3.83~seventy four.84 | 85 |

| R/RF28 | 25mm | 16mm | .18~three | three.37~one hundred thirty five.09 | one hundred thirty |

| R/RF38 | 25mm | 16mm | .eighteen~three | 3.forty one~134.eighty two | two hundred |

| R/RF48 | 30mm | 19mm | .eighteen~5.5 | 3.83~176.88 | three hundred |

| R/RF58 | 35mm | 19mm | .18~7.5 | 4.39~186.89 | 450 |

| R/RF68 | 35mm | 19mm | .18~7.five | 4.29~199.eighty one | 600 |

| R/RF78 | 40mm | 24mm | .18~11 | five.21~195.24 | 820 |

| R/RF88 | 50mm | 28mm | .55~22 | 5.36~246.fifty four | 1550 |

| R/RF98 | 60mm | 38mm | .fifty five~30 | four.49~289.six | 3000 |

| R/RF108 | 70mm | 42mm | two.2~forty five | five.06~245.five | 4300 |

| R/RF138 | 90mm | 55mm | 5.5~fifty five | five.51~223.34 | 8000 |

| R/RF148 | 110mm | 55mm | 11~ninety | five.00~163.46 | 13000 |

| R/RF168 | 120mm | 70mm | eleven~160 | eight.seventy seven~196.forty one | 18000 |

one Stage

| Models | Output Shaft Dia. | Input Shaft Dia. | Electrical power(kW) | Ratio | Max. Torque(Nm) |

| RX/RXF38 | 20mm | 16mm | .18~1.1 | 1.6~3.76 | 20 |

| RX/RXF58 | 20mm | 19mm | .18~5.five | one.3~5.5 | 70 |

| RX/RXF68 | 25mm | 19mm | .18~7.five | 1.4~6.07 | a hundred thirty five |

| RX/RXF78 | 30mm | 24mm | one.1~11 | 1.42~5.sixty three | 215 |

| RX/RXF88 | 40mm | 28mm | three~22 | 1.39~6.forty four | four hundred |

| RX/RXF98 | 50mm | 38mm | five.5~thirty | 1.forty two~5.eighty two | 600 |

| RX/RXF108 | 60mm | 42mm | 7.5~forty five | one.44~6.sixty five | 830 |

| RX/RXF128 | 75mm | 55mm | seven.5~90 | one.fifty six~6.47 | 1110 |

| RX/RXF158 | 90mm | 70mm | eleven~132 | 1.sixty three~6.22 | 1680 |

Packaging & CZPT

Packaging & Shipping and delivery

Velocity Reducer Worm Gearbox CZPT Specifics:Plastic Luggage, Plywood Cases

Port:ZheJiang /HangZhou

Organization Profile

1.A lot more than 35 a long time expertise in R&D and producing, export gear motors & industrial gearboxes.

two. Standardization of the gearbox series

three. CZPT design and style ability for large CZPT & CZPT ized gearboxes.

four. CZPT quality gearboxes and confirmed options service provider.

five. Rigorous good quality handle method, secure top quality.

six. Less than 2% of the high quality grievances.

seven. Modular design, short shipping time.

8. Rapid reaction & specialist providers.

Customer visiting:

After Income Services

| Pre-sale solutions | 1. Pick gear model. |

| two.Design and manufacture items according to clients’ unique need. | |

| three.Prepare technical private for consumers | |

| Services in the course of marketing | 1.Pre-verify and take merchandise in advance of shipping and delivery. |

| two. Help consumers to draft solving strategies. | |

| After-sale companies | 1.Support consumers to put together for the 1st development plan. |

| 2. Prepare the very first-line operators. | |

| three.Consider initiative to remove the problems swiftly. | |

| four. Provide specialized exchanging. |

FAQ

one.Q:What sorts of gearbox can you produce for us?

A:Principal products of CZPT company: UDL collection pace variator,RV collection CZPT reducer, ATA series shaft mounted gearbox, X,B collection equipment reducer,

P collection planetary gearbox and R, S, K, and F series CZPT cal-tooth reducer, far more

than one particular hundred versions and 1000’s of specs

two.Q:Can you make as per CZPT drawing?

A: Indeed, we offer CZPT ized services for CZPT ers.

three.Q:What is your conditions of payment ?

A: 30% CZPT payment by T/T right after signing the contract.70% before shipping

4.Q:What is your MOQ?

A: 1 Set

If you are fascinated in CZPT merchandise, welcome you make contact with me.

Our staff will assistance any need to have you may have.

AC motors differ from several other varieties of motors, specifically some of the far more acquainted DC (direct present) motors, by several critical standards. The most fundamental of these is the reality that an AC motor relies entirely on the alternating current around its circuit to create effective mechanical energy. We are going to discuss this unique method in a lot more depth in the adhering to sections of this information.

china manufacturer manufacturer sales Heavy-Duty H Series Parallel Shaft Industrial Gearbox manufacturers

Solution Description

Weighty-Responsibility H Sequence Parallel Shaft CZPT Gearbox

H Series Parallel Shaft Gearbox (Helical Gears)(TLH sequence is the other title of H sequence)

1. Product Number

Types: H1,H2,H3,H4 Parallel Shaft Gearbox

Measurements: 1,2,3,4,5,24,twenty five,26

two. Product Qualities

(1)Big torque selection, capable of horizontal mounting and vertical mounting.

(2)Large-effectiveness and CZPT lifestyle-span, substantial permissible axial and radial hundreds.

(3)Low sounds, high trustworthiness and compact construction and so on.

(4)Output shafts variety: solid shaft, hollow shaft and hollow shaft with shrink disk.

(5)Minimal noise, higher reliability and compact structure.

3.Purposes:

The products are broadly used in electric power, coal, cement, metallurgy, harbor, agriculture, shipping and delivery, lifting, setting protection, stage, logistic, weaving, paper making, light-weight sector, plastics and other locations.

4. CZPT of H sequence gearbox

| Materials | Housing: HT250 forged iron |

| Gear: 20CrMnTi H, higher grade allo with carburization |

|

| surface hardness: fifty eight-62HRC |

|

| center hardness: 33-48HRC |

|

| Grinding precision quality: ISO1328-1: 1995 class 5-six |

|

| surfaceness: .8 |

|

| carburization depth: .6-1.5mm |

|

| Bearing: 42CrMo |

5.Complex knowledge:

| Power | Ratio | Input CZPT | Torque | Transmission stage | Mounting position |

| 4-5000kw | one.twenty five-450 | 1450RMP, 960RMP, 710RMP | 2300-900000N. M | one phase, 2 phase, 3 phase, 4 stage | Vertical, horizontal |

six.Product images:

Our firm :

AOKMAN® was started in 1982, which has far more than 36 several years in R & D and production of gearboxes, gears, shaft, motor and spare elements.

We can provide the proper resolution for uncountable apps. Our merchandise are broadly utilised in the ranges of metallurgical, steel, mining, pulp and paper, sugar and alcoholic beverages marketplace and CZPT other sorts of machines with a robust presence in the global marketplace.

AOKMAN® has become a reliable provider, able to source substantial quality gearboxes.With 36 many years experience, we assure you the utmost trustworthiness and stability for equally item and solutions.

Customer checking out:

FAQ:

1.Q:What varieties of gearbox can you generate for us?

A:Primary items of CZPT firm: UDL collection pace variator,RV sequence CZPT reducer, ATA series shaft mounted gearbox, X,B sequence gear reducer,

P sequence planetary gearbox and R, S, K, and F series CZPT cal-tooth reducer, far more

than one particular hundred designs and hundreds of technical specs

two.Q:Can you make as for each CZPT drawing?

A: Sure, we provide CZPT ized service for CZPT ers.

3.Q:What is your conditions of payment ?

A: 30% CZPT payment by T/T after signing the deal.70% prior to delivery

four.Q:What is your MOQ?

A: 1 Set

If you have any demand from customers for CZPT products make sure you come to feel cost-free to contact me.

Polyphase motors can be possibly two-section or 3-stage motors. They operate like solitary-period induction motors, but both one-phase and polyphase motors function on a rotating magnetic area. Their rotating magnetic fields are produced by two- or a few-phase currents passing by way of two or a lot more sets of coils. The rotating magnetic subject produces torque. Polyphase motors are utilised in applications that require substantial energy, these kinds of as the energy travel of compressors, hydraulic pumps, air conditioning compressors, and irrigation pumps.

china shop Industrial Transmission Drive RV Series Nmrv Reduction Gear Box Stainless Steel Worm Gearbox Speed Reducer manufacturers

Solution Description

Industrial Transmission CZPT Rv Series nmrv Reduction Equipment Box CZPT Metal Worm Gearbox CZPT Reducer

Goods Attributes

one. Produced of high-high quality aluminum alloy,mild bodyweight and CZPT -rusting

2. Massive output torque

three. Sleek in working and low in sound,can work CZPT time in dreadful circumstances.

four. CZPT in radiating efficiency.

five. CZPT -hunting in visual appeal,durable in service lifestyle and tiny in volume.

6. Suited for omnibearing installation.

Attributes of Worm Reducer /Gearbox

1.Widespread mounting dimensions.

two.Aluminum and solid iron housing.

three.Worm and worm wheel transmission.

four.Compact framework and light-bodyweight.

5.Wide variety of accessories.

Advantages of Worm Gearbox / Reducer

1.Exclusive housing layout will distinguish you from other rivals.

2.Numerous option for oil seal.

three.The proportions can be CZPT ized according to CZPT er’s demands.

|

Product No |

NMRV571, NMRV030, NMRV040, NMRV050, NMRV063, NMRV075, NMRV090, NMRV110, NMRV130, NMRV150 |

|

Ratio |

5,7.5,ten,fifteen,twenty,25,thirty,forty,fifty,60,80,a hundred |

|

Substance |

Housing: Dimensions twenty five-a hundred and ten Is CZPT Alloy, Dimension 110-one hundred fifty Is Cast-Iron |

|

Worm Wheel: ZCuSn10Pb1 |

|

|

Worm:20Cr |

|

|

Pinion:Tin Bronze |

|

|

Output Shaft: Metal-45# |

|

|

Variety |

Worm Gear CZPT Reducer / Gearbox / Reductor |

|

Coloration |

Personalized Color |

|

Packing |

Carton, Honey Comb Carton, CZPT Situation with CZPT Pallet |

|

Utilization |

Industrial CZPT , Foodstuff Stuff, Ceramics, CZPT , Packing, Dyeing, Wood Operating, CZPT , and so on. |

|

Flange |

IEC normal flange or CZPT ized dimensions |

|

Housing Material |

Aluminum&Forged iron |

|

Size |

eleven measurements(WMRV25~WMRV185) |

|

Electrical power |

.06~22 KW |

|

Nominal torque |

≤2548 N.m |

|

Ratio |

5~a hundred |

Associated Products

Firm Details

Polyphase motors can be both two-stage or 3-stage motors. They perform like one-phase induction motors, but equally single-section and polyphase motors run on a rotating magnetic field. Their rotating magnetic fields are generated by two- or 3-stage currents passing through two or more sets of coils. The rotating magnetic field creates torque. Polyphase motors are utilised in purposes that require high electrical power, this sort of as the power travel of compressors, hydraulic pumps, air conditioning compressors, and irrigation pumps.