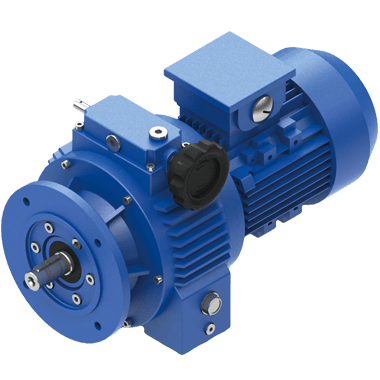

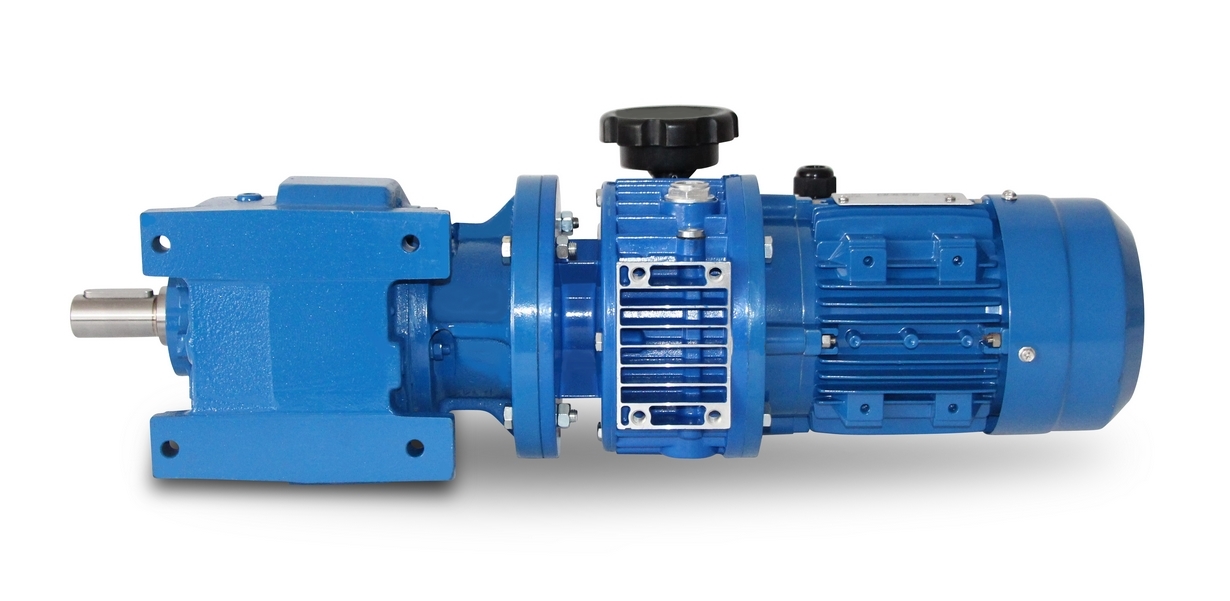

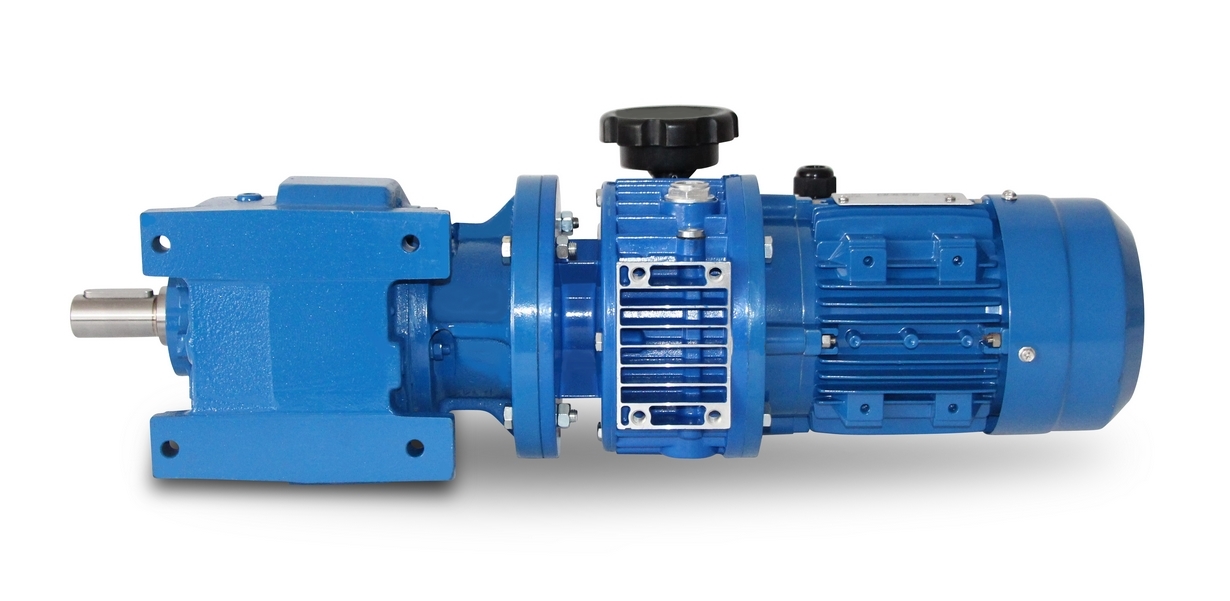

Product Description

You can choose the 1 type that you need form these product introction.

If you have any question,please contact me.

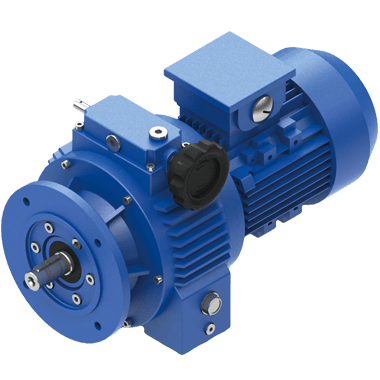

HangZhou CHINAMFG Machinery Co.,ltd is a company specialized in research, manufacture and service of speed gearbox. Ever since establishment, we have been persisting in technical innovation, advancing the techonology to our products while maintaining our strict quality controls. It is the reason that our products branding ”Xihu (West Lake) Dis.n” have enjoyed such successful global sales.

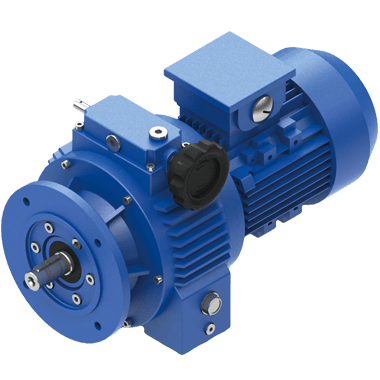

At present, our company mainly supplies 5 series products as RV worm gearbox, UDL series speed variator,PC series helical gear unit,G3 helical geared motor and SRC helical gearbox. The products are widely applied in the mechanical equipment field such as food and beverage,cement,package,chemical and dyeing, rubber and plastic, CNC machine tool,etc.

Our products have been processed ISO 9001 Quality System Certification and exported to Italy,Spain,Britain,Poland,Turkey.The USA and other European countries,earn the good reputation with our outstanding quality and service.

Customers first,customers satisfaction, excellent after sale service and incessant innovation are our tenet and motto. We will go all out to provide all the customers with high quality and service. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical and Horizontal |

| Samples: |

US$ 69.9/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What safety considerations are associated with the installation and operation of variator motors?

When installing and operating variator motors, several safety considerations should be taken into account. Here’s a detailed explanation:

Variator motors, like any other electrical or mechanical equipment, require proper installation, operation, and maintenance to ensure safe and reliable performance. Here are some key safety considerations associated with the installation and operation of variator motors:

- Electrical Safety: Variator motors are powered by electricity, so it’s crucial to follow electrical safety guidelines during installation and operation. This includes ensuring proper grounding of the motor and adhering to local electrical codes and regulations. It’s important to have a qualified electrician handle the electrical connections and ensure that the motor is properly wired and protected from electrical hazards.

- Mechanical Safety: Variator motors often have moving parts and may be connected to mechanical systems. During installation, it’s necessary to ensure that the motor is securely mounted and aligned with the driven equipment. Adequate guarding should be provided to prevent accidental contact with moving parts, such as belts, pulleys, or couplings. Properly sized and rated couplings, belts, and other mechanical components should be used to ensure safe and reliable operation.

- Overload Protection: Variator motors should be protected against overloading. Overloading can cause overheating, reduced motor life, and potential safety hazards. It’s important to select a motor with the appropriate power rating for the application and ensure that it’s not subjected to excessive loads. Additional overload protection devices, such as thermal protectors or overload relays, may be necessary to safeguard the motor and prevent damage or hazards.

- Heat Dissipation: Variator motors can generate heat during operation, especially at higher speeds or under heavy loads. Sufficient ventilation and cooling should be provided to dissipate the heat effectively. Adequate clearance around the motor and proper ventilation in the motor enclosure or installation area can help prevent overheating and ensure safe operation. It’s important to follow the manufacturer’s recommendations regarding cooling and ventilation requirements.

- Environmental Considerations: The installation and operation of variator motors should consider the environmental conditions in which they will be used. For example, if the motor will be exposed to moisture, dust, or corrosive substances, appropriate measures should be taken to protect the motor against these elements. This may include using sealed motor enclosures or installing the motor in a suitable protective housing. Additionally, if the motor will be used in hazardous locations, such as areas with flammable gases or dust, it must comply with the applicable safety standards and requirements.

- Proper Maintenance: Regular maintenance is essential for the safe and reliable operation of variator motors. This includes periodic inspection, cleaning, and lubrication of the motor and its components. It’s important to follow the manufacturer’s maintenance guidelines and schedule to ensure that the motor remains in good working condition. Any signs of wear, damage, or abnormal operating conditions should be addressed promptly to prevent safety risks.

- Training and Awareness: Proper training and awareness of the operators and maintenance personnel are crucial for safe operation and maintenance of variator motors. Operators should be knowledgeable about the motor’s operation, control features, and emergency procedures. Maintenance personnel should be trained to perform maintenance tasks safely and be aware of potential hazards associated with the motor. Regular safety training and refresher courses can help promote a safe working environment.

It’s important to note that the specific safety considerations may vary depending on the motor model, application, and local regulations. Therefore, it’s recommended to consult the manufacturer’s documentation and guidelines, as well as relevant safety standards, to ensure that all necessary safety precautions are followed during the installation and operation of variator motors.

What resources are available for further learning about the principles and applications of variator motors?

There are several resources available for further learning about the principles and applications of variator motors. Here’s a detailed explanation:

1. Books and Publications: Numerous books and publications cover the principles, design, and applications of variator motors. Some recommended titles include “Variable Speed AC Drives with Inverter Output Filters” by Jaroslaw Guzinski and Haitham Abu-Rub, “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and Bill Drury, and “Variable Frequency Drives: Installation and Troubleshooting” by Glen A. Mazur. These resources provide in-depth knowledge on variator motor technology, control strategies, and practical implementation.

2. Online Courses and Tutorials: Online learning platforms like Udemy, Coursera, and edX offer courses and tutorials on electric motors, motor control, and power electronics. These courses cover variator motor principles, operation, and applications, providing a structured learning experience with video lectures, quizzes, and assignments. Some courses are specifically focused on variable frequency drives (VFDs) and their applications.

3. Technical Documentation and Application Notes: Manufacturers of variator motors and associated equipment often provide technical documentation, application notes, and white papers that delve into the principles and applications of variator motors. These resources can be found on the manufacturers’ websites and offer valuable insights into motor selection, installation, and operation.

4. Professional Journals and Research Papers: Academic and professional journals in the fields of electrical engineering, power electronics, and industrial automation publish research papers and articles on variator motors. IEEE Transactions on Industrial Electronics, IEEE Industry Applications Magazine, and International Journal of Electrical Power & Energy Systems are some examples of publications that cover topics related to variator motors. Access to these resources may require subscriptions or membership in relevant professional organizations.

5. Webinars and Online Presentations: Webinars and online presentations hosted by motor manufacturers, industry associations, or technology companies can provide valuable insights into the principles and applications of variator motors. These events often feature subject matter experts who share their knowledge, discuss case studies, and answer questions from participants. Recordings of past webinars are sometimes made available for on-demand viewing.

6. Industry Forums and Discussion Groups: Online forums and discussion groups focused on electrical engineering, motor control, or industrial automation can be valuable resources for learning about variator motors. Platforms like Electrical Engineering Stack Exchange, Control.com, and LinkedIn groups dedicated to motor control offer opportunities to ask questions, engage in discussions, and learn from the experiences of industry professionals.

7. Manufacturer Training Programs: Some variator motor manufacturers offer training programs and workshops that cover the principles, operation, and applications of their products. These programs may include hands-on exercises, demonstrations, and technical support. Contacting the manufacturers directly or checking their websites can provide information on available training opportunities.

When exploring these resources, it’s important to consider the credibility of the source, relevance to specific applications, and the date of publication to ensure the information aligns with the latest advancements in variator motor technology.

By utilizing these resources, individuals can deepen their understanding of variator motors and enhance their knowledge of the principles and applications associated with this technology.

In which industries are variator motors commonly used for different applications?

Variator motors, with their adjustable speed control capabilities, find applications in various industries where precise speed control, energy efficiency, and adaptability to changing operational requirements are essential. Here are some industries where variator motors are commonly used for different applications:

- Industrial Manufacturing: Variator motors are extensively utilized in industrial manufacturing processes. They can be found in machinery and equipment such as conveyors, mixers, extruders, and packaging machines. The ability to adjust the speed of these motors allows for efficient material handling, mixing, blending, and product packaging.

- Material Handling and Logistics: In the material handling and logistics industry, variator motors are commonly employed in conveyor systems. These motors enable precise control of product movement, allowing for smooth and efficient transfer of goods in manufacturing plants, warehouses, airports, and distribution centers.

- Pumping and Water Treatment: Variator motors are utilized in pumping systems for water treatment, wastewater management, and irrigation. The adjustable speed control feature enables the optimization of pumping rates based on demand, resulting in energy savings and improved system efficiency.

- HVAC (Heating, Ventilation, and Air Conditioning): Variator motors play a crucial role in HVAC systems, particularly in fans and blowers. By adjusting the motor speed, these systems can modulate the airflow and temperature control, ensuring optimal comfort and energy efficiency in commercial buildings, residential complexes, and industrial facilities.

- Automotive Industry: Variator motors are used in various applications within the automotive industry. They can be found in vehicle cooling systems, power steering systems, and engine control units. The ability to adjust the motor speed allows for efficient cooling, precise steering assistance, and optimal engine performance.

- Renewable Energy: Variator motors are employed in renewable energy systems such as wind turbines and solar tracking systems. In wind turbines, variator motors enable the adjustment of blade pitch for optimal power generation. In solar tracking systems, they control the movement of solar panels to maximize exposure to sunlight throughout the day.

- Food and Beverage: Variator motors find applications in the food and beverage industry, particularly in mixing, blending, and processing equipment. They enable precise control of speed and agitation, ensuring consistent product quality and efficient production processes.

These are just a few examples of industries where variator motors are commonly used. Their versatility and ability to provide adjustable speed control make them suitable for a wide range of applications across different sectors.

editor by CX 2024-05-15

China Good quality Transmission Geared Motor Unit RV Screw Drive Lifts Stepper Cyclo Cycloidal Extruder Helical Planetary Bevel Worm Speed Variator Gear Reducer Gearbox vacuum pump

Product Description

Worm gearbox speed reducer electric motor dc are on sale with high quality for you

SMRV 571-150 worm gear box with flange and electric motor

SMRV+NMRV Double Stage Arrangement Reduction Gear Box

RV Series Worm Gearbox

worm speed reducer

nmrv worm gear motor

You can choose the 1 type that you need form these product introction.

If you have any question,please contact me.

HangZhou CHINAMFG Machinery Co.,ltd is a company specialized in research, manufacture and service of speed gearbox. Ever since establishment, we have been persisting in technical innovation, advancing the techonology to our products while maintaining our strict quality controls. It is the reason that our products branding ”Xihu (West Lake) Dis.n” have enjoyed such successful global sales.

At present, our company mainly supplies 5 series products as RV worm gearbox, UDL series speed variator,PC series helical gear unit,G3 helical geared motor and SRC helical gearbox. The products are widely applied in the mechanical equipment field such as food and beverage,cement,package,chemical and dyeing, rubber and plastic, CNC machine tool,etc.

Our products have been processed ISO 9001 Quality System Certification and exported to Italy,Spain,Britain,Poland,Turkey.The USA and other European countries,earn the good reputation with our outstanding quality and service.

Customers first,customers satisfaction, excellent after sale service and incessant innovation are our tenet and motto. We will go all out to provide all the customers with high quality and service. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What safety considerations are associated with the installation and operation of variator motors?

When installing and operating variator motors, several safety considerations should be taken into account. Here’s a detailed explanation:

Variator motors, like any other electrical or mechanical equipment, require proper installation, operation, and maintenance to ensure safe and reliable performance. Here are some key safety considerations associated with the installation and operation of variator motors:

- Electrical Safety: Variator motors are powered by electricity, so it’s crucial to follow electrical safety guidelines during installation and operation. This includes ensuring proper grounding of the motor and adhering to local electrical codes and regulations. It’s important to have a qualified electrician handle the electrical connections and ensure that the motor is properly wired and protected from electrical hazards.

- Mechanical Safety: Variator motors often have moving parts and may be connected to mechanical systems. During installation, it’s necessary to ensure that the motor is securely mounted and aligned with the driven equipment. Adequate guarding should be provided to prevent accidental contact with moving parts, such as belts, pulleys, or couplings. Properly sized and rated couplings, belts, and other mechanical components should be used to ensure safe and reliable operation.

- Overload Protection: Variator motors should be protected against overloading. Overloading can cause overheating, reduced motor life, and potential safety hazards. It’s important to select a motor with the appropriate power rating for the application and ensure that it’s not subjected to excessive loads. Additional overload protection devices, such as thermal protectors or overload relays, may be necessary to safeguard the motor and prevent damage or hazards.

- Heat Dissipation: Variator motors can generate heat during operation, especially at higher speeds or under heavy loads. Sufficient ventilation and cooling should be provided to dissipate the heat effectively. Adequate clearance around the motor and proper ventilation in the motor enclosure or installation area can help prevent overheating and ensure safe operation. It’s important to follow the manufacturer’s recommendations regarding cooling and ventilation requirements.

- Environmental Considerations: The installation and operation of variator motors should consider the environmental conditions in which they will be used. For example, if the motor will be exposed to moisture, dust, or corrosive substances, appropriate measures should be taken to protect the motor against these elements. This may include using sealed motor enclosures or installing the motor in a suitable protective housing. Additionally, if the motor will be used in hazardous locations, such as areas with flammable gases or dust, it must comply with the applicable safety standards and requirements.

- Proper Maintenance: Regular maintenance is essential for the safe and reliable operation of variator motors. This includes periodic inspection, cleaning, and lubrication of the motor and its components. It’s important to follow the manufacturer’s maintenance guidelines and schedule to ensure that the motor remains in good working condition. Any signs of wear, damage, or abnormal operating conditions should be addressed promptly to prevent safety risks.

- Training and Awareness: Proper training and awareness of the operators and maintenance personnel are crucial for safe operation and maintenance of variator motors. Operators should be knowledgeable about the motor’s operation, control features, and emergency procedures. Maintenance personnel should be trained to perform maintenance tasks safely and be aware of potential hazards associated with the motor. Regular safety training and refresher courses can help promote a safe working environment.

It’s important to note that the specific safety considerations may vary depending on the motor model, application, and local regulations. Therefore, it’s recommended to consult the manufacturer’s documentation and guidelines, as well as relevant safety standards, to ensure that all necessary safety precautions are followed during the installation and operation of variator motors.

What resources are available for further learning about the principles and applications of variator motors?

There are several resources available for further learning about the principles and applications of variator motors. Here’s a detailed explanation:

1. Books and Publications: Numerous books and publications cover the principles, design, and applications of variator motors. Some recommended titles include “Variable Speed AC Drives with Inverter Output Filters” by Jaroslaw Guzinski and Haitham Abu-Rub, “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and Bill Drury, and “Variable Frequency Drives: Installation and Troubleshooting” by Glen A. Mazur. These resources provide in-depth knowledge on variator motor technology, control strategies, and practical implementation.

2. Online Courses and Tutorials: Online learning platforms like Udemy, Coursera, and edX offer courses and tutorials on electric motors, motor control, and power electronics. These courses cover variator motor principles, operation, and applications, providing a structured learning experience with video lectures, quizzes, and assignments. Some courses are specifically focused on variable frequency drives (VFDs) and their applications.

3. Technical Documentation and Application Notes: Manufacturers of variator motors and associated equipment often provide technical documentation, application notes, and white papers that delve into the principles and applications of variator motors. These resources can be found on the manufacturers’ websites and offer valuable insights into motor selection, installation, and operation.

4. Professional Journals and Research Papers: Academic and professional journals in the fields of electrical engineering, power electronics, and industrial automation publish research papers and articles on variator motors. IEEE Transactions on Industrial Electronics, IEEE Industry Applications Magazine, and International Journal of Electrical Power & Energy Systems are some examples of publications that cover topics related to variator motors. Access to these resources may require subscriptions or membership in relevant professional organizations.

5. Webinars and Online Presentations: Webinars and online presentations hosted by motor manufacturers, industry associations, or technology companies can provide valuable insights into the principles and applications of variator motors. These events often feature subject matter experts who share their knowledge, discuss case studies, and answer questions from participants. Recordings of past webinars are sometimes made available for on-demand viewing.

6. Industry Forums and Discussion Groups: Online forums and discussion groups focused on electrical engineering, motor control, or industrial automation can be valuable resources for learning about variator motors. Platforms like Electrical Engineering Stack Exchange, Control.com, and LinkedIn groups dedicated to motor control offer opportunities to ask questions, engage in discussions, and learn from the experiences of industry professionals.

7. Manufacturer Training Programs: Some variator motor manufacturers offer training programs and workshops that cover the principles, operation, and applications of their products. These programs may include hands-on exercises, demonstrations, and technical support. Contacting the manufacturers directly or checking their websites can provide information on available training opportunities.

When exploring these resources, it’s important to consider the credibility of the source, relevance to specific applications, and the date of publication to ensure the information aligns with the latest advancements in variator motor technology.

By utilizing these resources, individuals can deepen their understanding of variator motors and enhance their knowledge of the principles and applications associated with this technology.

How does the efficiency of variator motors compare to other types of motors?

The efficiency of variator motors can vary depending on the specific design, application, and operating conditions. However, in general, variator motors can offer comparable or even higher efficiency compared to other types of motors. Here are some key points to consider:

- Variable Speed Operation: Variator motors excel in variable speed operations where the motor speed can be adjusted to match the load and process requirements. By running the motor at a speed that precisely meets the demand, variator motors can significantly reduce energy losses associated with running at fixed speeds. This level of control contributes to high overall system efficiency.

- Energy Savings through Speed Control: The ability to adjust the motor speed in variator motors allows for energy savings. By operating the motor at lower speeds when full speed is not required, variator motors can achieve energy efficiency gains. This is particularly relevant in applications with varying loads or processes that do not constantly require maximum speed.

- Improved Power Factor: Variator motors with adjustable speed control, such as those incorporating variable frequency drives (VFDs), can improve the power factor of the motor system. Power factor is a measure of how effectively electrical power is being used. By optimizing the motor speed and voltage, VFDs can improve the power factor, resulting in reduced reactive power consumption and improved energy efficiency.

- Motor Design and Technology: The efficiency of variator motors can also be influenced by the motor design and the use of advanced technologies. Manufacturers are continually improving motor designs, incorporating high-quality materials, precision manufacturing techniques, and efficient cooling systems to enhance motor efficiency. Additionally, advancements in motor technologies, such as the use of permanent magnet materials and improved motor control algorithms, contribute to higher overall efficiency.

- Comparison with Other Motor Types: When compared to traditional fixed-speed motors, variator motors generally offer higher efficiency due to their ability to adjust speed according to the load. In applications where variable speed control is required, variator motors can outperform fixed-speed motors in terms of energy savings, precise control, and overall system efficiency.

It’s important to note that the efficiency of variator motors can also depend on factors such as motor size, load characteristics, maintenance practices, and system design. Therefore, it’s advisable to consider specific motor specifications, consult with manufacturers, and conduct energy efficiency assessments to determine the most suitable motor type for a given application.

editor by CX 2024-04-26

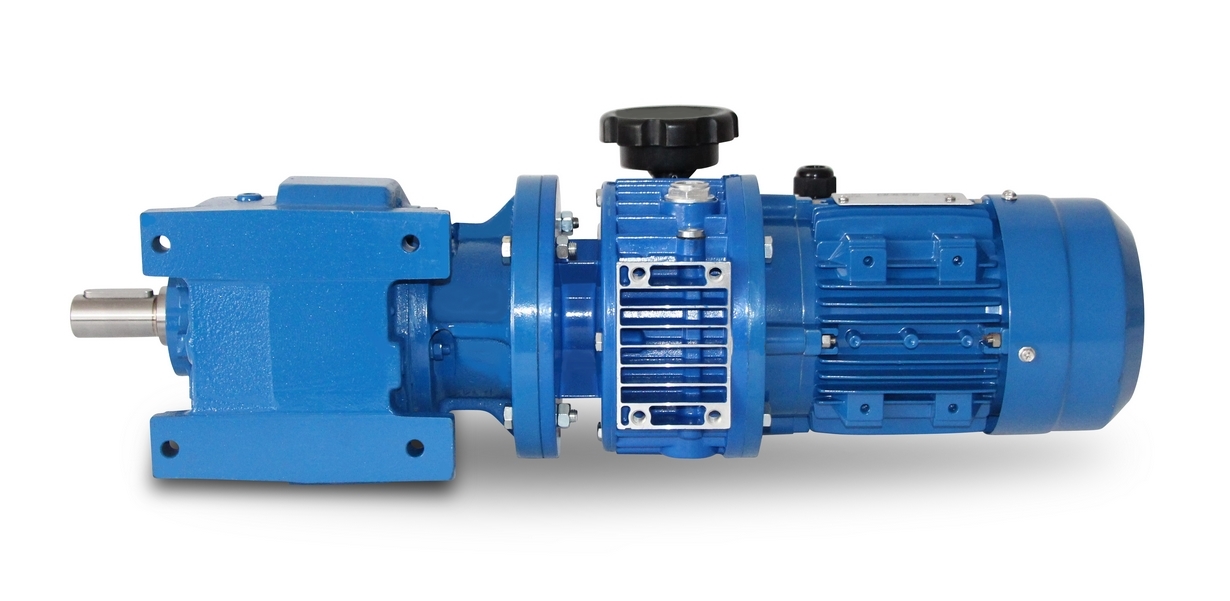

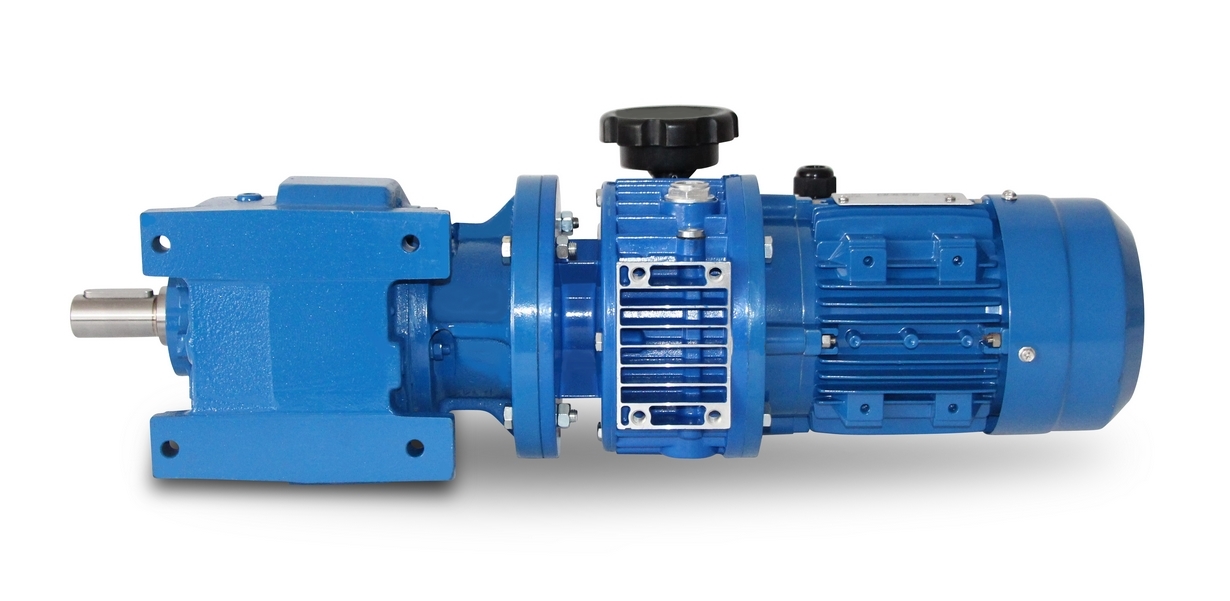

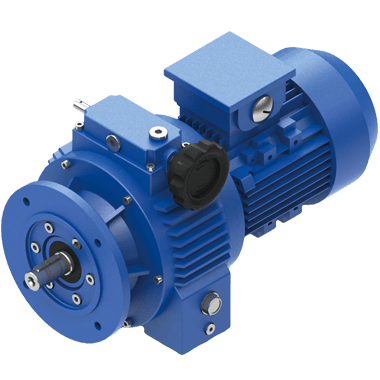

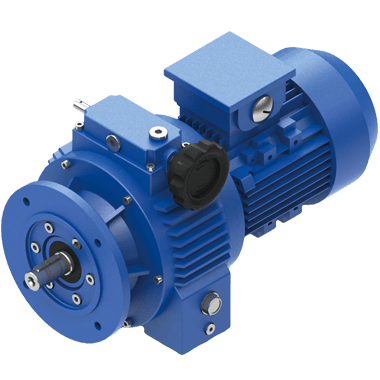

China wholesaler Transmission Geared Motor Unit Screw Drive Lifts Stepper Extruder Helical Planetary Bevel Worm Speed Variator Gear Reducer Gearbox vacuum pump oil near me

Product Description

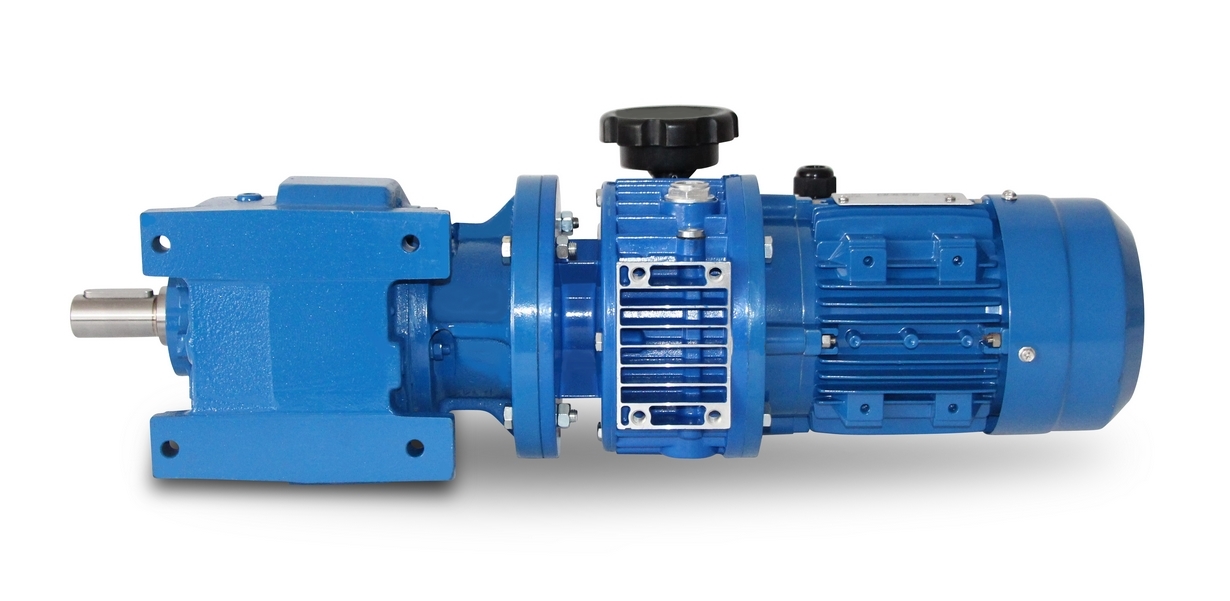

SRC HELICAL GEARBOX

Products Description

We produce speed reducers in strict accordance with ISO9001 standard to provide our customers with high quality gearboxes at competitive prices. Our gearboxes are equipped with accessories from international famous brands, such as lubricant from Shell brand, and bearing from CHINAMFG brand. The housing and gear are produced in our company under stringent quality control. All our products are available in large stocks, and we can also provide you with customized reducer solutions, pleasefeel confident to contact us.

|

TRC: code for gear units series |

|

1. No code means foot-mounted |

|

2.F: B5 flange mounted |

|

3.Z:B14 flange mounted |

|

Specification code of gear units 01,02.03.04 |

|

B01,MO1……means foot code,without flange |

|

1.I.II1.B5 Output flange specification, defaultl not to write out is ok |

|

2. IECinput flange |

|

3.HS: Shaft input |

|

Transmission ratio of gear units |

|

1.M1: Mounting positio, default mounting position M1 not to write out is ok |

|

1.No mark means without motor |

|

2. Model motos (poles of power)voltage – frequency |

|

voltage – frequency |

|

|

|

|

HangZhou CHINAMFG Machinery Co., Ltd.

History: More than 20 years of experience in the manufacture of reducer products.Scale: Cover working area of 13300 square. meters,have more than 113 employees.

Technology: A group of professional . technical engineers and a strong R&D team.

Management: Scientific ERP management and strict quality control system.

Equipment: 50 CNC lathes,6 machining. centers, 6 gear grinding machines, 2 high-speed.hard hobbing machines, 12 gear hobbing

machines. 10 CNC cylindrical grinding machines,4 CNC internal grinding machines 1spectrometer, high-speed gear shaping 1 machine,

2 gear measuring centers 1 coordinate measuring instrument.

lnnovation: Continuously diversify products range to satisfy customers’needs.Production capacity: 1000 pcs/day.

Long-term supplier of world-class companies: t he main markets are in Southea st Asia, Europe, Middle East.

Marketing model: All export business.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Step: | Double-Step |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does the size and power rating of variator motors impact their performance?

The size and power rating of variator motors have a significant impact on their performance. Here’s a detailed explanation of how these factors influence motor performance:

- Torque Output: The size and power rating of a variator motor directly affect its torque output. Generally, larger and higher-rated motors can deliver higher torque levels, allowing them to handle heavier or more demanding loads. A motor with higher torque capability can provide better acceleration, overcome resistance, and maintain stable operation under varying load conditions.

- Speed Range: The size and power rating of the motor also influence its speed range. Motors with higher power ratings can typically achieve a broader speed range, allowing for more flexibility in matching the motor’s speed to the application’s requirements. Smaller motors may have a more limited speed range, which can impact their suitability for certain applications that require a wide range of speeds.

- Overload Capacity: Larger and higher-rated variator motors generally have a higher overload capacity. They can handle temporary increases in load or momentary peak demands without experiencing significant performance degradation or overheating. This makes them suitable for applications with intermittent or cyclical loads, where occasional high torque requirements may arise.

- Efficiency: The size and power rating of a motor can impact its efficiency. In general, larger motors tend to have higher efficiencies, especially when operating near their rated capacity. Higher efficiency means less energy loss as heat and improved overall energy utilization. It’s important to select a motor with an appropriate power rating to ensure efficient operation while avoiding oversized motors that may operate at low efficiency levels.

- Physical Dimensions: The size of a variator motor directly affects its physical dimensions and weight. Larger motors typically have larger physical footprints and may be heavier. The physical dimensions of the motor can impact its installation requirements, space availability, and integration into the overall system design. It’s important to consider the available space and mounting requirements when selecting a motor of a suitable size.

- Heat Dissipation: The size and power rating of a motor influence its heat dissipation capabilities. Higher-rated motors generally generate more heat during operation, and larger motors have a larger surface area for heat dissipation. Adequate heat dissipation is crucial to prevent overheating and ensure the motor’s long-term reliability. It’s important to consider the motor’s cooling requirements, such as ventilation or cooling mechanisms, to maintain optimal operating temperatures.

- Cost: The size and power rating of a variator motor can impact its cost. Generally, larger and higher-rated motors tend to be more expensive than smaller ones due to the increased materials, manufacturing complexity, and performance capabilities. It’s important to balance the motor’s size, power rating, and associated cost with the specific requirements and budget of the application.

In summary, the size and power rating of variator motors significantly influence their performance in terms of torque output, speed range, overload capacity, efficiency, physical dimensions, heat dissipation, and cost. It’s crucial to carefully consider these factors when selecting a motor to ensure it meets the requirements of the application and delivers optimal performance and reliability.

What are the key components and technologies used in modern variator motors?

Modern variator motors incorporate several key components and technologies to enable their variable speed and adjustable torque capabilities. Here’s a detailed explanation:

1. Motor Stator and Rotor: The motor stator and rotor are fundamental components of variator motors. The stator consists of a stationary set of windings that generate a rotating magnetic field when energized. The rotor, typically mounted on the motor shaft, contains conductive bars or coils that interact with the magnetic field and produce mechanical rotation.

2. Power Electronics: Variator motors rely on power electronics components, such as inverters or variable frequency drives (VFDs), to control the motor’s speed and torque. These devices convert the incoming AC power supply into the appropriate voltage and frequency required by the motor. Power electronics also enable smooth and precise adjustment of motor operating parameters, facilitating variable speed operation.

3. Sensors and Feedback Devices: Variator motors often incorporate sensors and feedback devices to monitor motor performance and provide input for control algorithms. Common sensors used include speed sensors, position sensors, temperature sensors, and current sensors. These sensors provide real-time information about the motor’s operating conditions, allowing the control system to adjust motor parameters accordingly.

4. Control Algorithms and Software: Modern variator motors employ sophisticated control algorithms and software to regulate motor speed, torque, and other operating parameters. These algorithms process the sensor data and generate control signals to adjust the power electronics and optimize motor performance. Advanced control techniques, such as field-oriented control (FOC) or model predictive control (MPC), may be used to achieve precise and efficient motor operation.

5. Variable Speed Drive Mechanisms: Variator motors employ various mechanisms to achieve variable speed operation. These mechanisms can include adjustable pulley systems, belt drives, gearboxes, or electronic control of motor winding configurations. The specific mechanism depends on the motor’s design and application requirements.

6. Efficiency-Enhancing Technologies: Modern variator motors incorporate technologies aimed at improving energy efficiency and reducing losses. These technologies may include the use of high-efficiency motor designs, such as permanent magnet motors or synchronous reluctance motors. Additionally, advanced insulation materials, optimized motor cooling systems, and reduced friction bearings can contribute to enhanced motor efficiency.

7. Communication and Networking: Some variator motors feature communication and networking capabilities to enable integration with industrial automation systems or the Internet of Things (IoT). These capabilities facilitate remote monitoring, control, and data exchange, allowing for enhanced motor performance analysis, predictive maintenance, and system integration.

8. Safety and Protection Features: Modern variator motors incorporate safety and protection features to safeguard the motor and the surrounding equipment. These features may include overcurrent protection, overvoltage protection, short-circuit protection, thermal protection, and fault detection mechanisms. These measures ensure safe and reliable operation and help prevent damage to the motor in case of abnormal operating conditions.

The specific components and technologies used in variator motors can vary depending on the motor’s type, design, and application requirements. Motor manufacturers continuously innovate and incorporate advancements in materials, electronics, and control systems to improve motor performance, efficiency, and reliability.

What are the advantages of using variator motors in industrial settings?

Variator motors offer several advantages when used in industrial settings. Here are some key benefits:

- Flexible Speed Control: One of the primary advantages of variator motors is their ability to provide flexible speed control. Unlike traditional motors that operate at a fixed speed, variator motors allow for adjustable speed settings. This flexibility enables industrial processes to be optimized for different operational requirements, such as varying loads, different stages of production, or specific process demands.

- Energy Efficiency: Variator motors can help improve energy efficiency in industrial settings. By adjusting the motor speed to match the required output, these motors can avoid the energy losses associated with running at fixed speeds. Operating the motor at lower speeds when the full speed is not necessary can lead to significant energy savings. This energy efficiency not only reduces operational costs but also contributes to sustainability and environmental conservation efforts.

- Precise Process Control: The ability to finely tune the speed of variator motors enables precise process control in industrial settings. Processes that require accurate manipulation of speed, such as mixing, blending, and conveyance, can benefit from variator motors. The adjustable speed allows for better control over product quality, consistency, and production rates.

- Adaptability to Changing Loads: Variator motors are well-suited for applications that experience varying loads. The adjustable speed control allows the motor to respond to changes in load conditions, compensating for fluctuations and ensuring optimal performance. This adaptability is particularly advantageous in industries where load variations are common, such as material handling, conveyor systems, and production lines with varying throughput requirements.

- Reduced Mechanical Stress: In some industrial processes, sudden starts or stops and rapid speed changes can subject mechanical components to excessive stress, leading to premature wear and tear. Variator motors can mitigate this issue by providing smooth and controlled acceleration and deceleration. The ability to gradually ramp up or down the motor speed reduces mechanical stress on the system, prolonging the lifespan of equipment and minimizing maintenance needs.

- Improved Productivity: Variator motors can contribute to improved productivity in industrial settings. The adjustable speed control allows for process optimization, reducing cycle times and enhancing overall efficiency. By matching the motor speed to the specific requirements of each stage of production, variator motors can help streamline operations and increase productivity.

These advantages make variator motors a valuable choice for a wide range of industrial applications. Their flexibility, energy efficiency, precise control, adaptability, and productivity enhancements contribute to improved performance and cost-effectiveness in industrial settings.

editor by CX 2024-04-24

China Best Sales Nmrv090 Series Wpa Worm Gear Reducer Electronic Variator Hollow Shaft Motor Speed manufacturer

Product Description

Technical data list:

| Type: | Worm Gear Speed Reducer |

| Model: | NMRV571–150 |

| Ratio: | 1:7.5,10,15,20,25,30,40,50,60,80,100 |

| Color: | Blue/Silver Or On Customer Request |

| Material | Housing: Blue-Coloured Cast-Iron Worm Gear-Copper-10-3# Worm-20CrMn Ti with carburizing and quenching, surface harness is 56-62HRC Shaft-chromium steel-45# |

| Lubricant: | Synthetic&Mineral |

| Bearing: | C&U Bearing |

| Seal: | high quality |

| Warranty: | -30-40°C |

| ICE FLANGE | 80B5,90B5,100B5,112B5,132B5,160B5 |

| Rated power: | 0.06KW,0.12KW,0.25KW,0.75KW,1.5KW,3KW,5.5KW,7.5KW |

| Application | Metallurgical machinery, food machinery, stage machinery, welding machinery, road machinery, amusement machines, packaging machinery, Rubber and plastic machinery, environmental protection machinery ,engineering machinery, construction machinery, machine tool industry, automotive industry, logistics and transportation and so on |

| NMRV | PAM | N | M | P | D | |||||||||||

| ICE | 5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | ||||

| 25 | 56B14 | 50 | 65 | 80 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | |||

| 30 | 63B5 | 95 | 115 | 140 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | |||

| 63B14 | 60 | 75 | 90 | |||||||||||||

| 56B5 | 80 | 100 | 120 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | ||

| 56B14 | 50 | 65 | 80 | |||||||||||||

| 40 | 71B5 | 110 | 130 | 160 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | ||||

| 71B14 | 70 | 85 | 105 | |||||||||||||

| 63B5 | 95 | 115 | 140 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | |

| 63B14 | 60 | 75 | 90 | |||||||||||||

| 56B5 | 80 | 100 | 120 | 9 | 9 | 9 | 9 | |||||||||

| 50 | 80B5 | 130 | 165 | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | |||||

| 80B14 | 80 | 100 | 120 | |||||||||||||

| 71B5 | 110 | 130 | 160 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | ||

| 71B14 | 70 | 85 | 105 | |||||||||||||

| 63B5 | 95 | 115 | 140 | 11 | 11 | 11 | 11 | 11 | ||||||||

| 63 | 90B5 | 130 | 165 | 200 | 24 | 24 | 24 | 24 | 24 | 24 | ||||||

| 90B14 | 95 | 115 | 140 | |||||||||||||

| 80B5 | 130 | 165 | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | ||||

| 80B14 | 80 | 100 | 120 | |||||||||||||

| 71B5 | 110 | 130 | 160 | 14 | 14 | 14 | 14 | 14 | ||||||||

| 71B14 | 70 | 85 | 105 | |||||||||||||

| 75 | 100/112B5 | 180 | 215 | 250 | 28 | 28 | 28 | |||||||||

| 100/112B14 | 110 | 130 | 150 | |||||||||||||

| 90B5 | 130 | 165 | 200 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | ||||||

| 90B14 | 95 | 115 | 140 | |||||||||||||

| 80B5 | 130 | 165 | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | |||||

| 80B14 | 80 | 100 | 120 | |||||||||||||

| 71B5 | 110 | 130 | 160 | 14 | 14 | 14 | 14 | |||||||||

| 90 | 100/112B5 | 190 | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | ||||||

| 100/112B14 | 110 | 130 | 160 | |||||||||||||

| 90B5 | 130 | 165 | 200 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | ||||

| 90B14 | 95 | 115 | 140 | |||||||||||||

| 80B5 | 130 | 165 | 200 | 19 | 19 | 19 | 19 | 19 | ||||||||

| 80B14 | 80 | 100 | 120 | |||||||||||||

| 110 | 132B5 | 230 | 265 | 300 | 38 | 38 | 38 | 38 | ||||||||

| 100/112B5 | 180 | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | ||||

| 90B5 | 130 | 165 | 200 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | ||||||

| 80B5 | 130 | 165 | 200 | 19 | 19 | |||||||||||

| 130 | 132B5 | 230 | 265 | 300 | 38 | 38 | 38 | 38 | 38 | 38 | 38 | |||||

| 100/112B5 | 180 | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | ||||||

| 90B5 | 130 | 165 | 200 | 24 | 24 | |||||||||||

| 150 | 160B5 | 250 | 300 | 350 | 42 | 42 | 42 | 42 | 42 | |||||||

| 132B5 | 230 | 265 | 250 | 38 | 38 | 38 | 38 | 38 | 38 | |||||||

| 100/112B5 | 180 | 215 | 200 | 28 | 28 | 28 | 28 | |||||||||

Components:

1. Housing: Die-cast Aluminum Alloy Gearbox (RV571~RV090)

Cast Iron Gearbox (RV110~RV150)

2. Worm Wheel: Wearable Tin Bronze Alloy, Aluminum Bronze Alloy

3. Worm Shaft: 20Cr Steel, carburizing, quenching, grinding, surface hardness 56-62HRC, 0.3-0.5mm remaining carburized layer after precise grinding

4. Input Configurations:

Equipped with Electric Motors (AC Motor, Brake Motor, DC Motor, Servo Motor)

IEC-normalized Motor Flange

CHINAMFG Shaft Input

Worm Shaft Tail Extension Input

5. Output Configurations: Keyed Hollow Shaft Output

Hollow Shaft with Output Flange

Plug-in CHINAMFG Shaft Output

6. Spare Parts: Worm Shaft Tail Extension, Single Output Shaft, Double Output Shaft, Output Flange, Torque Arm, Dust Cover

7. Gearbox Painting:

Aluminum Alloy Gearbox:

After Shot Blasting, Anticorrosion Treatment and Phosphating, Paint with the Color of RAL 5571 Gentian Blue or RAL 7035 Light Grey

Cast Iron Gearbox:

After Painting with Red Antirust Paint, Paint with the Color of RAL 5571 Gentian Blue

Workshop show

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in single color box. If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance. Other payments terms, pls negotiate with us in advance, we can discuss.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 30 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.We welcome sample order.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Single-Step |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What safety considerations are associated with the installation and operation of variator motors?

When installing and operating variator motors, several safety considerations should be taken into account. Here’s a detailed explanation:

Variator motors, like any other electrical or mechanical equipment, require proper installation, operation, and maintenance to ensure safe and reliable performance. Here are some key safety considerations associated with the installation and operation of variator motors:

- Electrical Safety: Variator motors are powered by electricity, so it’s crucial to follow electrical safety guidelines during installation and operation. This includes ensuring proper grounding of the motor and adhering to local electrical codes and regulations. It’s important to have a qualified electrician handle the electrical connections and ensure that the motor is properly wired and protected from electrical hazards.

- Mechanical Safety: Variator motors often have moving parts and may be connected to mechanical systems. During installation, it’s necessary to ensure that the motor is securely mounted and aligned with the driven equipment. Adequate guarding should be provided to prevent accidental contact with moving parts, such as belts, pulleys, or couplings. Properly sized and rated couplings, belts, and other mechanical components should be used to ensure safe and reliable operation.

- Overload Protection: Variator motors should be protected against overloading. Overloading can cause overheating, reduced motor life, and potential safety hazards. It’s important to select a motor with the appropriate power rating for the application and ensure that it’s not subjected to excessive loads. Additional overload protection devices, such as thermal protectors or overload relays, may be necessary to safeguard the motor and prevent damage or hazards.

- Heat Dissipation: Variator motors can generate heat during operation, especially at higher speeds or under heavy loads. Sufficient ventilation and cooling should be provided to dissipate the heat effectively. Adequate clearance around the motor and proper ventilation in the motor enclosure or installation area can help prevent overheating and ensure safe operation. It’s important to follow the manufacturer’s recommendations regarding cooling and ventilation requirements.

- Environmental Considerations: The installation and operation of variator motors should consider the environmental conditions in which they will be used. For example, if the motor will be exposed to moisture, dust, or corrosive substances, appropriate measures should be taken to protect the motor against these elements. This may include using sealed motor enclosures or installing the motor in a suitable protective housing. Additionally, if the motor will be used in hazardous locations, such as areas with flammable gases or dust, it must comply with the applicable safety standards and requirements.

- Proper Maintenance: Regular maintenance is essential for the safe and reliable operation of variator motors. This includes periodic inspection, cleaning, and lubrication of the motor and its components. It’s important to follow the manufacturer’s maintenance guidelines and schedule to ensure that the motor remains in good working condition. Any signs of wear, damage, or abnormal operating conditions should be addressed promptly to prevent safety risks.

- Training and Awareness: Proper training and awareness of the operators and maintenance personnel are crucial for safe operation and maintenance of variator motors. Operators should be knowledgeable about the motor’s operation, control features, and emergency procedures. Maintenance personnel should be trained to perform maintenance tasks safely and be aware of potential hazards associated with the motor. Regular safety training and refresher courses can help promote a safe working environment.

It’s important to note that the specific safety considerations may vary depending on the motor model, application, and local regulations. Therefore, it’s recommended to consult the manufacturer’s documentation and guidelines, as well as relevant safety standards, to ensure that all necessary safety precautions are followed during the installation and operation of variator motors.

Are there cost considerations when choosing variator motors for industrial use?

Yes, there are several cost considerations that come into play when choosing variator motors for industrial use. Here’s a detailed explanation:

When selecting variator motors for industrial applications, it’s important to evaluate not only the initial purchase cost but also the overall cost of ownership throughout the motor’s lifespan. Here are some key cost considerations to keep in mind:

- Motor Cost: The initial purchase cost of the variator motor is an important consideration. The cost can vary depending on factors such as motor power rating, brand, quality, and additional features. It’s essential to compare prices from different suppliers and manufacturers to ensure a competitive and reasonable cost for the motor.

- Efficiency: The energy efficiency of the variator motor can have a significant impact on long-term operating costs. More efficient motors consume less energy, resulting in reduced electricity bills. It’s advisable to choose high-efficiency motors that meet or exceed the minimum efficiency standards set by regulatory bodies, such as the International Electrotechnical Commission (IEC) or the National Electrical Manufacturers Association (NEMA). Although high-efficiency motors may have a higher initial cost, the energy savings over the motor’s lifespan can offset the additional investment.

- Maintenance and Service: Consider the maintenance requirements and associated costs of variator motors. Motors that require regular maintenance, such as lubrication, bearing replacements, or brush inspections, may have higher maintenance costs compared to maintenance-free or sealed motor designs. It’s important to factor in the anticipated maintenance needs and costs when evaluating the overall cost of ownership.

- Durability and Reliability: Variator motors that are built to withstand harsh operating conditions and have a long service life can offer cost advantages in the long run. Although more durable and reliable motors may have a higher upfront cost, they can minimize the need for premature motor replacements, reduce downtime, and lower maintenance and repair expenses. It’s crucial to assess the motor’s quality, reputation, and warranty provisions to gauge its expected durability and reliability.

- Control and Automation: Variator motors often come with various control options and compatibility with automation systems. While these features can enhance operational efficiency and control, they may have associated costs. Consider the cost of control devices, such as variable frequency drives (VFDs), sensors, and monitoring equipment. Additionally, if integrating the motor into an existing automation system, ensure compatibility and account for any necessary upgrades or modifications.

- Application-Specific Requirements: Some industrial applications may have specific motor requirements that can impact costs. For example, if the motor needs to operate in extreme temperatures, hazardous environments, or corrosive atmospheres, special motor designs or materials may be necessary, which can increase costs. It’s important to evaluate any application-specific requirements and associated costs when selecting variator motors.

- Future Expandability: Consider the scalability and expandability of the motor system. If there are possibilities of future capacity expansions or modifications to the industrial process, choosing a motor that can accommodate such changes can prevent the need for a costly motor replacement in the future.

By carefully considering these cost factors, industrial users can make informed decisions when selecting variator motors that strike a balance between upfront costs and long-term operational expenses. It’s advisable to consult with motor suppliers, engineers, and industry experts to assess the specific cost considerations relevant to the industrial application and ensure the optimal motor choice.

What are the advantages of using variator motors in industrial settings?

Variator motors offer several advantages when used in industrial settings. Here are some key benefits:

- Flexible Speed Control: One of the primary advantages of variator motors is their ability to provide flexible speed control. Unlike traditional motors that operate at a fixed speed, variator motors allow for adjustable speed settings. This flexibility enables industrial processes to be optimized for different operational requirements, such as varying loads, different stages of production, or specific process demands.

- Energy Efficiency: Variator motors can help improve energy efficiency in industrial settings. By adjusting the motor speed to match the required output, these motors can avoid the energy losses associated with running at fixed speeds. Operating the motor at lower speeds when the full speed is not necessary can lead to significant energy savings. This energy efficiency not only reduces operational costs but also contributes to sustainability and environmental conservation efforts.

- Precise Process Control: The ability to finely tune the speed of variator motors enables precise process control in industrial settings. Processes that require accurate manipulation of speed, such as mixing, blending, and conveyance, can benefit from variator motors. The adjustable speed allows for better control over product quality, consistency, and production rates.

- Adaptability to Changing Loads: Variator motors are well-suited for applications that experience varying loads. The adjustable speed control allows the motor to respond to changes in load conditions, compensating for fluctuations and ensuring optimal performance. This adaptability is particularly advantageous in industries where load variations are common, such as material handling, conveyor systems, and production lines with varying throughput requirements.

- Reduced Mechanical Stress: In some industrial processes, sudden starts or stops and rapid speed changes can subject mechanical components to excessive stress, leading to premature wear and tear. Variator motors can mitigate this issue by providing smooth and controlled acceleration and deceleration. The ability to gradually ramp up or down the motor speed reduces mechanical stress on the system, prolonging the lifespan of equipment and minimizing maintenance needs.

- Improved Productivity: Variator motors can contribute to improved productivity in industrial settings. The adjustable speed control allows for process optimization, reducing cycle times and enhancing overall efficiency. By matching the motor speed to the specific requirements of each stage of production, variator motors can help streamline operations and increase productivity.

These advantages make variator motors a valuable choice for a wide range of industrial applications. Their flexibility, energy efficiency, precise control, adaptability, and productivity enhancements contribute to improved performance and cost-effectiveness in industrial settings.

editor by CX 2024-04-19

China best High Efficiency Worm Gear Box Wps Wpa Geared Motor with Electric Motor vacuum pump adapter

Product Description

Product description

High Efficiency Worm Gear Box WPS WPA Geared Motor With Electric Motor

|

Size |

Ratio |

A |

B |

E |

F |

H |

M |

N |

|

40 |

1/5 1/10 1/15 1/20 1/25 1/30 1/40 1/50 1/60 |

142 |

112 |

70 |

80 |

135 |

90 |

100 |

|

50 |

175 |

145 |

95 |

110 |

180 |

120 |

140 |

|

|

60 |

195 |

165 |

105 |

120 |

210 |

130 |

150 |

|

|

70 |

234 |

195 |

115 |

150 |

243 |

150 |

190 |

|

|

80 |

264 |

210 |

135 |

180 |

273 |

170 |

220 |

|

|

100 |

300 |

245 |

155 |

220 |

340 |

190 |

260 |

|

|

120 |

385 |

285 |

180 |

260 |

405 |

230 |

320 |

|

|

135 |

435 |

320 |

200 |

290 |

455 |

250 |

350 |

|

|

155 |

507 |

387 |

220 |

320 |

490 |

280 |

390 |

|

|

175 |

550 |

407 |

250 |

350 |

565 |

310 |

430 |

|

|

200 |

594 |

480 |

290 |

390 |

625 |

360 |

480 |

|

|

250 |

710 |

560 |

380 |

480 |

730 |

460 |

560 |

Our Gearbox has many items for your choosing and we can produce as per your drawing or sample to meet your special request

1. Large output torque

2. Safe, reliable, economical and durable

3. Stable transmission, quiet operation

4. High carrying ability

5. High modularization design, may equip with various outer power input conveniently. Same machine type may equip with various power motor. It is easy to realize the combination and junction between every machine type

6. Transmission ratio: Fine division, wide scope. The combined machine type may form very large transmission ratio, i. E. Output very low rotary speed.

7. Form of installation: The position to be installed is not limited.

8. High strength, compact the box body of high strength cast iron, gear and gear shaft adapts the gas carbonization, quenching and fine grinding process, therefore the bearing capacity of unit volume is high.

9. Long life: Under the condition of correct type chosen(including choosing suitable operation parament ) normal operation and maintenance, the life if main parts speed reducer(except wearing parts)should not be less than 20000 hours. The wearing parts include lubricating oil, oil seal and bearing.

10. Low noise: Because main parts of speed reducer are processed, and tested critically, therefore the noise of speed reducer is low.

11.Our gear box have reached the advance international level, can replace the same kind of products imported.

Recommend product

Marine Gearbox For Work Boat

Gearbox Manufacturers For Agricultural Machine

90 Degree Reducer For Concrete Mixer

Worm Gearbox Reduction For Conveyor Mill Machine

CHINAMFG High Torque Transmission Gearboxes

Gear Reducers For Belt Conveyor

Speed Worm Gear Reducer

HangZhou CHINAMFG Industry Co., Ltd. is a specialized supplier of a full range of chains, sprockets, gears, gear racks, v belt pulley, timing pulley, V-belts, couplings, machined parts and so on.

Due to our CHINAMFG in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements, we have obtained the trust of buyers worldwide. Having accumulated precious experience in cooperating with foreign customers, our products are selling well in the American, European, South American and Asian markets. Our products are manufactured by modern computerized machinery and equipment. Meanwhile, our products are manufactured according to high quality standards, and complying with the international advanced standard criteria.

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.

Additionally, all our production procedures are in compliance with ISO9001 standards. We also can design and make non-standard products to meet customers’ special requirements. Quality and credit are the bases that make a corporation alive. We will provide best services and high quality products with all sincerity. If you need any information or samples, please contact us and you will have our soon reply.

FAQ:

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 10 workdays.

2.Production Lead-times: 20-40 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we’ll check.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Output Speed: | 17.5-186.7 R/Min |

|---|---|

| Applicable Industries: | Hotels, Manufacturing Plant, Machinery |

| Customized Support: | OEM, ODM |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are variator motors suitable for applications requiring precise speed control?

Yes, variator motors are generally suitable for applications requiring precise speed control. Here’s a detailed explanation:

Variator motors, also known as variable speed motors or adjustable speed motors, are designed to provide adjustable speed control over a wide range. They allow the user to vary the motor’s speed according to the specific requirements of the application. This flexibility makes them well-suited for applications that demand precise speed control.

Here are some reasons why variator motors are suitable for applications requiring precise speed control:

- Speed Adjustment Range: Variator motors offer a wide range of adjustable speeds, allowing for precise control over the motor’s rotational speed. Depending on the specific model and type of variator motor, the speed adjustment range can vary from a few RPM (Revolutions Per Minute) to thousands of RPM. This versatility enables the motor to operate at different speeds, accommodating varying process or load requirements.

- Smooth Speed Transitions: Variator motors can provide smooth and gradual speed transitions. They offer precise speed control without sudden jolts or jerks during acceleration or deceleration. This feature is especially important in applications where precise speed control is critical for maintaining product quality, preventing damage to sensitive equipment, or ensuring smooth operation of processes.

- Speed Accuracy and Stability: Variator motors can achieve high speed accuracy and stability. They can maintain the desired speed setting within tight tolerances, minimizing deviations and fluctuations. This level of control is essential in applications that require precise synchronization, coordination with other system components, or adherence to specific speed profiles.

- Control Options: Variator motors often come with various control options, allowing for precise speed adjustments. These options can include manual control through potentiometers or dials, digital control through interface panels or keypads, or even programmable control through communication protocols such as Modbus or Ethernet. The availability of different control options enhances the motor’s suitability for applications requiring precise speed control.

- Response Time: Variator motors can typically achieve fast response times when adjusting the speed. They can quickly respond to speed commands or changes in the control signal, allowing for precise and immediate adjustments. This responsiveness is beneficial in applications where rapid speed changes or dynamic response is required to meet changing operational conditions.

- Closed-Loop Control Capability: Some variator motors are equipped with closed-loop control capabilities. Closed-loop control involves using feedback sensors, such as encoders or tachometers, to continuously monitor the motor’s actual speed and compare it to the desired speed. The control system adjusts the motor’s speed based on this feedback, ensuring precise speed control and compensating for any variations or disturbances.

- Application Versatility: Variator motors are versatile and can be used in a wide range of applications requiring precise speed control. They find applications in industries such as manufacturing, automation, robotics, HVAC (heating, ventilation, and air conditioning), conveyors, pumps, fans, and many others.

However, it’s important to note that the suitability of variator motors for precise speed control may vary depending on factors such as the specific motor model, control system, and the desired level of precision. It’s recommended to consult the motor manufacturer or an expert in motor control to determine the best solution for a particular application.

Can variator motors be used in conjunction with renewable energy sources?

Yes, variator motors can be used in conjunction with renewable energy sources. Here’s a detailed explanation:

Renewable energy sources, such as solar power, wind power, hydroelectric power, or biomass, are increasingly being adopted to reduce reliance on fossil fuels and decrease greenhouse gas emissions. Variator motors offer compatibility and advantages when used in conjunction with renewable energy sources:

- Variable Speed Operation: Variator motors are well-suited for variable speed operation, which aligns with the intermittent and fluctuating nature of renewable energy sources. For example, solar power generation is dependent on sunlight availability, and wind power generation depends on wind speed. By adjusting the motor speed to match the available energy input, variator motors can optimize the use of renewable energy and enhance overall system efficiency.

- Energy Harvesting: Variator motors can be utilized for energy harvesting applications in renewable energy systems. For instance, in wind turbines, variator motors can function as generators to harvest and convert mechanical energy from the wind into electrical energy. Similarly, in hydroelectric power systems, variator motors can be used as generators to convert the potential energy of flowing water into electricity. This energy harvesting capability makes variator motors a valuable component in renewable energy generation.

- Grid Integration: Variator motors can facilitate the integration of renewable energy systems with the electrical grid. They can provide power conditioning functions by controlling the voltage, frequency, and power factor of the generated renewable energy. This ensures the compatibility and stability of the power output from renewable sources, allowing seamless integration with the grid and enabling efficient utilization of the generated energy.

- Load Balancing and Energy Storage: Variator motors can contribute to load balancing and energy storage in renewable energy systems. During periods of excess energy generation, when the renewable energy source produces more power than required, variator motors can be used to store the excess energy in energy storage systems, such as batteries or flywheels. Later, when the renewable energy source produces less power than demanded, the stored energy can be released by the variator motors to balance the load and ensure a continuous and stable power supply.

- Efficiency Optimization: Variator motors enable efficiency optimization when combined with renewable energy sources. By adjusting the motor speed and torque based on the available renewable energy input, variator motors can operate in the most efficient range, maximizing energy conversion efficiency and minimizing energy losses. This optimization contributes to overall system efficiency and improved utilization of renewable energy resources.

The use of variator motors in conjunction with renewable energy sources offers benefits such as enhanced system efficiency, increased renewable energy utilization, and improved grid integration. However, it’s important to consider specific requirements, system compatibility, and the expertise of motor manufacturers and renewable energy professionals when implementing such systems. Consulting with experts in the field can help ensure the optimal integration and performance of variator motors in renewable energy applications.

What is a variator motor, and how does it differ from traditional motors?

A variator motor, also known as a variable speed motor, is a type of motor that allows for adjustable speed control. Unlike traditional motors that operate at a fixed speed, variator motors provide the ability to vary the rotational speed to meet specific application requirements. Here are some key points differentiating variator motors from traditional motors:

- Speed Control: The primary difference between variator motors and traditional motors is the ability to control the speed. Traditional motors typically operate at a fixed speed determined by the motor’s design and the frequency of the power supply. In contrast, variator motors feature mechanisms that allow for adjustable speed control, enabling users to increase or decrease the rotational speed as needed.

- Operating Principle: Variator motors achieve variable speed control through various mechanisms. One common approach is the use of adjustable transmission systems, such as variable frequency drives (VFDs) or mechanical gearboxes. These systems allow for changes in the motor’s output speed by adjusting the input power frequency or gear ratio. Other variator motors may employ electronic or hydraulic control systems to modulate the motor’s speed based on input signals or user commands.

- Application Flexibility: The ability to adjust the speed makes variator motors highly versatile and suitable for a wide range of applications. They can be employed in situations where precise speed control, energy efficiency, or the ability to adapt to changing operational requirements is critical. Variator motors find applications in industrial machinery, conveyors, pumps, fans, and other systems where speed modulation is beneficial.

- Energy Efficiency: Variator motors often exhibit higher energy efficiency compared to traditional motors, especially when operating at reduced speeds. By adjusting the motor’s speed to match the required output, variator motors can minimize energy wastage associated with running at fixed speeds. This energy-saving capability can lead to reduced operating costs and improved overall system efficiency.

- Cost and Complexity: Variator motors, due to their speed control capabilities, can be more complex and costly compared to traditional motors. The additional components required for speed modulation, such as variable frequency drives or control systems, can increase the overall system complexity and initial investment. However, the benefits of adjustable speed control and energy efficiency often outweigh the higher upfront costs in many applications.

In summary, a variator motor allows for adjustable speed control, enabling users to change the rotational speed to meet specific application requirements. With their ability to modulate speed, variator motors offer greater flexibility, energy efficiency, and application versatility compared to traditional motors.

editor by CX 2024-04-12

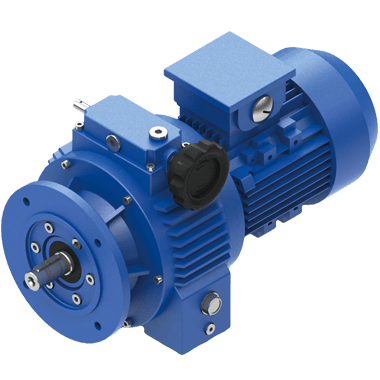

China Standard Nmrv Series Geared Motor with Variator Universal Box Structure Worm Gear Speed Reducer Used for Machine vacuum pump connector

Product Description

Geared motor with the variator

Description:

RV series Small worm gear box is a new-generation of products developed by our factory on the basis of perfecting WJ series products with compromise of advanced technology both at home and abroad. Small worm aluminium box appearance adopts advanced square box type structure. Its outer body is made of high quality, aluminium alloy die casting into forming. Small worm gearbox has the characteristics of small volume, light weight, high in radiating efficiency, large in output torque, smooth in running, stable transmission with low noise. It is beautiful and durable and it’s suitable for omni-bearing installation. It’s widely applied in light industry, chemicals, food, packing, pharmaceuticals etc.

Hot sale RV gear motor Characteristics:

1. Nmrv Small worm gear box

2. High quality bearings prevent leaks, contribute to flexibility in mountin-g and increase reducer life

3. NEMA and IEC motors inputs

4. Double-lip oil seals

5. O-rings are used to prevent leaks

6. Standard hollow output bore and optional plug in shafts provide greater flexibility.

7. Automated manufacturing process from an ISO9001 certified company assures quality, reliable gearing.

NMRV Small worm gear box Technical data:

Output torque: 4 – 1379 N. M

Model: RV 30-130

Speed ratio: 7.5 – 100

Input power 0.06 – 9.2 kw

Packaging & Shipping

Product package: Standard package, Package is wooden case, Or according to required.

Our Services:

Nmrv worm speed reducer Warranty Terms:

1.12 Months guarantee will be offered.

2. We will react during 24 hours after received the email required to ensure the recovery of buyer’s production line first.

3. The engineers will provide the trainings for operation, maintenace fix skill to make the workers better understanding

4. Free parts replacement in the warranty period.

About us: