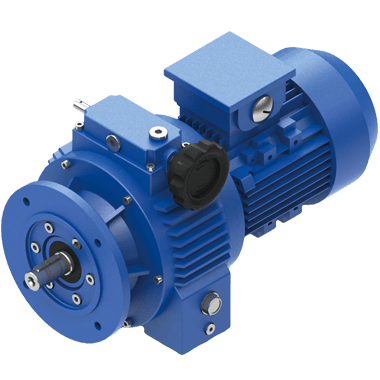

Product Description

You can choose the 1 type that you need form these product introction.

If you have any question,please contact me.

HangZhou CHINAMFG Machinery Co.,ltd is a company specialized in research, manufacture and service of speed gearbox. Ever since establishment, we have been persisting in technical innovation, advancing the techonology to our products while maintaining our strict quality controls. It is the reason that our products branding ”Xihu (West Lake) Dis.n” have enjoyed such successful global sales.

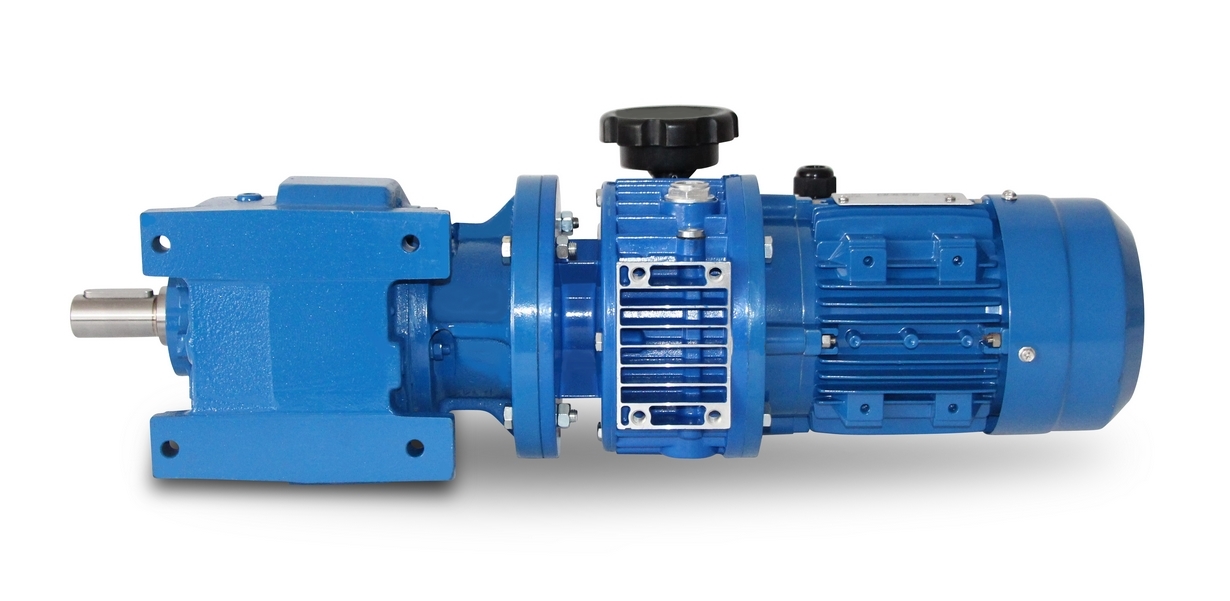

At present, our company mainly supplies 5 series products as RV worm gearbox, UDL series speed variator,PC series helical gear unit,G3 helical geared motor and SRC helical gearbox. The products are widely applied in the mechanical equipment field such as food and beverage,cement,package,chemical and dyeing, rubber and plastic, CNC machine tool,etc.

Our products have been processed ISO 9001 Quality System Certification and exported to Italy,Spain,Britain,Poland,Turkey.The USA and other European countries,earn the good reputation with our outstanding quality and service.

Customers first,customers satisfaction, excellent after sale service and incessant innovation are our tenet and motto. We will go all out to provide all the customers with high quality and service. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical and Horizontal |

| Samples: |

US$ 69.9/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What safety considerations are associated with the installation and operation of variator motors?

When installing and operating variator motors, several safety considerations should be taken into account. Here’s a detailed explanation:

Variator motors, like any other electrical or mechanical equipment, require proper installation, operation, and maintenance to ensure safe and reliable performance. Here are some key safety considerations associated with the installation and operation of variator motors:

- Electrical Safety: Variator motors are powered by electricity, so it’s crucial to follow electrical safety guidelines during installation and operation. This includes ensuring proper grounding of the motor and adhering to local electrical codes and regulations. It’s important to have a qualified electrician handle the electrical connections and ensure that the motor is properly wired and protected from electrical hazards.

- Mechanical Safety: Variator motors often have moving parts and may be connected to mechanical systems. During installation, it’s necessary to ensure that the motor is securely mounted and aligned with the driven equipment. Adequate guarding should be provided to prevent accidental contact with moving parts, such as belts, pulleys, or couplings. Properly sized and rated couplings, belts, and other mechanical components should be used to ensure safe and reliable operation.

- Overload Protection: Variator motors should be protected against overloading. Overloading can cause overheating, reduced motor life, and potential safety hazards. It’s important to select a motor with the appropriate power rating for the application and ensure that it’s not subjected to excessive loads. Additional overload protection devices, such as thermal protectors or overload relays, may be necessary to safeguard the motor and prevent damage or hazards.

- Heat Dissipation: Variator motors can generate heat during operation, especially at higher speeds or under heavy loads. Sufficient ventilation and cooling should be provided to dissipate the heat effectively. Adequate clearance around the motor and proper ventilation in the motor enclosure or installation area can help prevent overheating and ensure safe operation. It’s important to follow the manufacturer’s recommendations regarding cooling and ventilation requirements.

- Environmental Considerations: The installation and operation of variator motors should consider the environmental conditions in which they will be used. For example, if the motor will be exposed to moisture, dust, or corrosive substances, appropriate measures should be taken to protect the motor against these elements. This may include using sealed motor enclosures or installing the motor in a suitable protective housing. Additionally, if the motor will be used in hazardous locations, such as areas with flammable gases or dust, it must comply with the applicable safety standards and requirements.

- Proper Maintenance: Regular maintenance is essential for the safe and reliable operation of variator motors. This includes periodic inspection, cleaning, and lubrication of the motor and its components. It’s important to follow the manufacturer’s maintenance guidelines and schedule to ensure that the motor remains in good working condition. Any signs of wear, damage, or abnormal operating conditions should be addressed promptly to prevent safety risks.

- Training and Awareness: Proper training and awareness of the operators and maintenance personnel are crucial for safe operation and maintenance of variator motors. Operators should be knowledgeable about the motor’s operation, control features, and emergency procedures. Maintenance personnel should be trained to perform maintenance tasks safely and be aware of potential hazards associated with the motor. Regular safety training and refresher courses can help promote a safe working environment.

It’s important to note that the specific safety considerations may vary depending on the motor model, application, and local regulations. Therefore, it’s recommended to consult the manufacturer’s documentation and guidelines, as well as relevant safety standards, to ensure that all necessary safety precautions are followed during the installation and operation of variator motors.

What resources are available for further learning about the principles and applications of variator motors?

There are several resources available for further learning about the principles and applications of variator motors. Here’s a detailed explanation:

1. Books and Publications: Numerous books and publications cover the principles, design, and applications of variator motors. Some recommended titles include “Variable Speed AC Drives with Inverter Output Filters” by Jaroslaw Guzinski and Haitham Abu-Rub, “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and Bill Drury, and “Variable Frequency Drives: Installation and Troubleshooting” by Glen A. Mazur. These resources provide in-depth knowledge on variator motor technology, control strategies, and practical implementation.

2. Online Courses and Tutorials: Online learning platforms like Udemy, Coursera, and edX offer courses and tutorials on electric motors, motor control, and power electronics. These courses cover variator motor principles, operation, and applications, providing a structured learning experience with video lectures, quizzes, and assignments. Some courses are specifically focused on variable frequency drives (VFDs) and their applications.

3. Technical Documentation and Application Notes: Manufacturers of variator motors and associated equipment often provide technical documentation, application notes, and white papers that delve into the principles and applications of variator motors. These resources can be found on the manufacturers’ websites and offer valuable insights into motor selection, installation, and operation.

4. Professional Journals and Research Papers: Academic and professional journals in the fields of electrical engineering, power electronics, and industrial automation publish research papers and articles on variator motors. IEEE Transactions on Industrial Electronics, IEEE Industry Applications Magazine, and International Journal of Electrical Power & Energy Systems are some examples of publications that cover topics related to variator motors. Access to these resources may require subscriptions or membership in relevant professional organizations.

5. Webinars and Online Presentations: Webinars and online presentations hosted by motor manufacturers, industry associations, or technology companies can provide valuable insights into the principles and applications of variator motors. These events often feature subject matter experts who share their knowledge, discuss case studies, and answer questions from participants. Recordings of past webinars are sometimes made available for on-demand viewing.

6. Industry Forums and Discussion Groups: Online forums and discussion groups focused on electrical engineering, motor control, or industrial automation can be valuable resources for learning about variator motors. Platforms like Electrical Engineering Stack Exchange, Control.com, and LinkedIn groups dedicated to motor control offer opportunities to ask questions, engage in discussions, and learn from the experiences of industry professionals.

7. Manufacturer Training Programs: Some variator motor manufacturers offer training programs and workshops that cover the principles, operation, and applications of their products. These programs may include hands-on exercises, demonstrations, and technical support. Contacting the manufacturers directly or checking their websites can provide information on available training opportunities.

When exploring these resources, it’s important to consider the credibility of the source, relevance to specific applications, and the date of publication to ensure the information aligns with the latest advancements in variator motor technology.

By utilizing these resources, individuals can deepen their understanding of variator motors and enhance their knowledge of the principles and applications associated with this technology.

In which industries are variator motors commonly used for different applications?

Variator motors, with their adjustable speed control capabilities, find applications in various industries where precise speed control, energy efficiency, and adaptability to changing operational requirements are essential. Here are some industries where variator motors are commonly used for different applications:

- Industrial Manufacturing: Variator motors are extensively utilized in industrial manufacturing processes. They can be found in machinery and equipment such as conveyors, mixers, extruders, and packaging machines. The ability to adjust the speed of these motors allows for efficient material handling, mixing, blending, and product packaging.

- Material Handling and Logistics: In the material handling and logistics industry, variator motors are commonly employed in conveyor systems. These motors enable precise control of product movement, allowing for smooth and efficient transfer of goods in manufacturing plants, warehouses, airports, and distribution centers.

- Pumping and Water Treatment: Variator motors are utilized in pumping systems for water treatment, wastewater management, and irrigation. The adjustable speed control feature enables the optimization of pumping rates based on demand, resulting in energy savings and improved system efficiency.

- HVAC (Heating, Ventilation, and Air Conditioning): Variator motors play a crucial role in HVAC systems, particularly in fans and blowers. By adjusting the motor speed, these systems can modulate the airflow and temperature control, ensuring optimal comfort and energy efficiency in commercial buildings, residential complexes, and industrial facilities.

- Automotive Industry: Variator motors are used in various applications within the automotive industry. They can be found in vehicle cooling systems, power steering systems, and engine control units. The ability to adjust the motor speed allows for efficient cooling, precise steering assistance, and optimal engine performance.

- Renewable Energy: Variator motors are employed in renewable energy systems such as wind turbines and solar tracking systems. In wind turbines, variator motors enable the adjustment of blade pitch for optimal power generation. In solar tracking systems, they control the movement of solar panels to maximize exposure to sunlight throughout the day.

- Food and Beverage: Variator motors find applications in the food and beverage industry, particularly in mixing, blending, and processing equipment. They enable precise control of speed and agitation, ensuring consistent product quality and efficient production processes.

These are just a few examples of industries where variator motors are commonly used. Their versatility and ability to provide adjustable speed control make them suitable for a wide range of applications across different sectors.

editor by CX 2024-05-15

China Good quality Transmission Geared Motor Unit RV Screw Drive Lifts Stepper Cyclo Cycloidal Extruder Helical Planetary Bevel Worm Speed Variator Gear Reducer Gearbox vacuum pump

Product Description

Worm gearbox speed reducer electric motor dc are on sale with high quality for you

SMRV 571-150 worm gear box with flange and electric motor

SMRV+NMRV Double Stage Arrangement Reduction Gear Box

RV Series Worm Gearbox

worm speed reducer

nmrv worm gear motor

You can choose the 1 type that you need form these product introction.

If you have any question,please contact me.

HangZhou CHINAMFG Machinery Co.,ltd is a company specialized in research, manufacture and service of speed gearbox. Ever since establishment, we have been persisting in technical innovation, advancing the techonology to our products while maintaining our strict quality controls. It is the reason that our products branding ”Xihu (West Lake) Dis.n” have enjoyed such successful global sales.

At present, our company mainly supplies 5 series products as RV worm gearbox, UDL series speed variator,PC series helical gear unit,G3 helical geared motor and SRC helical gearbox. The products are widely applied in the mechanical equipment field such as food and beverage,cement,package,chemical and dyeing, rubber and plastic, CNC machine tool,etc.

Our products have been processed ISO 9001 Quality System Certification and exported to Italy,Spain,Britain,Poland,Turkey.The USA and other European countries,earn the good reputation with our outstanding quality and service.

Customers first,customers satisfaction, excellent after sale service and incessant innovation are our tenet and motto. We will go all out to provide all the customers with high quality and service. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What safety considerations are associated with the installation and operation of variator motors?

When installing and operating variator motors, several safety considerations should be taken into account. Here’s a detailed explanation:

Variator motors, like any other electrical or mechanical equipment, require proper installation, operation, and maintenance to ensure safe and reliable performance. Here are some key safety considerations associated with the installation and operation of variator motors:

- Electrical Safety: Variator motors are powered by electricity, so it’s crucial to follow electrical safety guidelines during installation and operation. This includes ensuring proper grounding of the motor and adhering to local electrical codes and regulations. It’s important to have a qualified electrician handle the electrical connections and ensure that the motor is properly wired and protected from electrical hazards.

- Mechanical Safety: Variator motors often have moving parts and may be connected to mechanical systems. During installation, it’s necessary to ensure that the motor is securely mounted and aligned with the driven equipment. Adequate guarding should be provided to prevent accidental contact with moving parts, such as belts, pulleys, or couplings. Properly sized and rated couplings, belts, and other mechanical components should be used to ensure safe and reliable operation.

- Overload Protection: Variator motors should be protected against overloading. Overloading can cause overheating, reduced motor life, and potential safety hazards. It’s important to select a motor with the appropriate power rating for the application and ensure that it’s not subjected to excessive loads. Additional overload protection devices, such as thermal protectors or overload relays, may be necessary to safeguard the motor and prevent damage or hazards.

- Heat Dissipation: Variator motors can generate heat during operation, especially at higher speeds or under heavy loads. Sufficient ventilation and cooling should be provided to dissipate the heat effectively. Adequate clearance around the motor and proper ventilation in the motor enclosure or installation area can help prevent overheating and ensure safe operation. It’s important to follow the manufacturer’s recommendations regarding cooling and ventilation requirements.

- Environmental Considerations: The installation and operation of variator motors should consider the environmental conditions in which they will be used. For example, if the motor will be exposed to moisture, dust, or corrosive substances, appropriate measures should be taken to protect the motor against these elements. This may include using sealed motor enclosures or installing the motor in a suitable protective housing. Additionally, if the motor will be used in hazardous locations, such as areas with flammable gases or dust, it must comply with the applicable safety standards and requirements.

- Proper Maintenance: Regular maintenance is essential for the safe and reliable operation of variator motors. This includes periodic inspection, cleaning, and lubrication of the motor and its components. It’s important to follow the manufacturer’s maintenance guidelines and schedule to ensure that the motor remains in good working condition. Any signs of wear, damage, or abnormal operating conditions should be addressed promptly to prevent safety risks.

- Training and Awareness: Proper training and awareness of the operators and maintenance personnel are crucial for safe operation and maintenance of variator motors. Operators should be knowledgeable about the motor’s operation, control features, and emergency procedures. Maintenance personnel should be trained to perform maintenance tasks safely and be aware of potential hazards associated with the motor. Regular safety training and refresher courses can help promote a safe working environment.

It’s important to note that the specific safety considerations may vary depending on the motor model, application, and local regulations. Therefore, it’s recommended to consult the manufacturer’s documentation and guidelines, as well as relevant safety standards, to ensure that all necessary safety precautions are followed during the installation and operation of variator motors.

What resources are available for further learning about the principles and applications of variator motors?

There are several resources available for further learning about the principles and applications of variator motors. Here’s a detailed explanation:

1. Books and Publications: Numerous books and publications cover the principles, design, and applications of variator motors. Some recommended titles include “Variable Speed AC Drives with Inverter Output Filters” by Jaroslaw Guzinski and Haitham Abu-Rub, “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and Bill Drury, and “Variable Frequency Drives: Installation and Troubleshooting” by Glen A. Mazur. These resources provide in-depth knowledge on variator motor technology, control strategies, and practical implementation.

2. Online Courses and Tutorials: Online learning platforms like Udemy, Coursera, and edX offer courses and tutorials on electric motors, motor control, and power electronics. These courses cover variator motor principles, operation, and applications, providing a structured learning experience with video lectures, quizzes, and assignments. Some courses are specifically focused on variable frequency drives (VFDs) and their applications.

3. Technical Documentation and Application Notes: Manufacturers of variator motors and associated equipment often provide technical documentation, application notes, and white papers that delve into the principles and applications of variator motors. These resources can be found on the manufacturers’ websites and offer valuable insights into motor selection, installation, and operation.

4. Professional Journals and Research Papers: Academic and professional journals in the fields of electrical engineering, power electronics, and industrial automation publish research papers and articles on variator motors. IEEE Transactions on Industrial Electronics, IEEE Industry Applications Magazine, and International Journal of Electrical Power & Energy Systems are some examples of publications that cover topics related to variator motors. Access to these resources may require subscriptions or membership in relevant professional organizations.

5. Webinars and Online Presentations: Webinars and online presentations hosted by motor manufacturers, industry associations, or technology companies can provide valuable insights into the principles and applications of variator motors. These events often feature subject matter experts who share their knowledge, discuss case studies, and answer questions from participants. Recordings of past webinars are sometimes made available for on-demand viewing.

6. Industry Forums and Discussion Groups: Online forums and discussion groups focused on electrical engineering, motor control, or industrial automation can be valuable resources for learning about variator motors. Platforms like Electrical Engineering Stack Exchange, Control.com, and LinkedIn groups dedicated to motor control offer opportunities to ask questions, engage in discussions, and learn from the experiences of industry professionals.

7. Manufacturer Training Programs: Some variator motor manufacturers offer training programs and workshops that cover the principles, operation, and applications of their products. These programs may include hands-on exercises, demonstrations, and technical support. Contacting the manufacturers directly or checking their websites can provide information on available training opportunities.

When exploring these resources, it’s important to consider the credibility of the source, relevance to specific applications, and the date of publication to ensure the information aligns with the latest advancements in variator motor technology.

By utilizing these resources, individuals can deepen their understanding of variator motors and enhance their knowledge of the principles and applications associated with this technology.

How does the efficiency of variator motors compare to other types of motors?

The efficiency of variator motors can vary depending on the specific design, application, and operating conditions. However, in general, variator motors can offer comparable or even higher efficiency compared to other types of motors. Here are some key points to consider:

- Variable Speed Operation: Variator motors excel in variable speed operations where the motor speed can be adjusted to match the load and process requirements. By running the motor at a speed that precisely meets the demand, variator motors can significantly reduce energy losses associated with running at fixed speeds. This level of control contributes to high overall system efficiency.

- Energy Savings through Speed Control: The ability to adjust the motor speed in variator motors allows for energy savings. By operating the motor at lower speeds when full speed is not required, variator motors can achieve energy efficiency gains. This is particularly relevant in applications with varying loads or processes that do not constantly require maximum speed.

- Improved Power Factor: Variator motors with adjustable speed control, such as those incorporating variable frequency drives (VFDs), can improve the power factor of the motor system. Power factor is a measure of how effectively electrical power is being used. By optimizing the motor speed and voltage, VFDs can improve the power factor, resulting in reduced reactive power consumption and improved energy efficiency.

- Motor Design and Technology: The efficiency of variator motors can also be influenced by the motor design and the use of advanced technologies. Manufacturers are continually improving motor designs, incorporating high-quality materials, precision manufacturing techniques, and efficient cooling systems to enhance motor efficiency. Additionally, advancements in motor technologies, such as the use of permanent magnet materials and improved motor control algorithms, contribute to higher overall efficiency.

- Comparison with Other Motor Types: When compared to traditional fixed-speed motors, variator motors generally offer higher efficiency due to their ability to adjust speed according to the load. In applications where variable speed control is required, variator motors can outperform fixed-speed motors in terms of energy savings, precise control, and overall system efficiency.

It’s important to note that the efficiency of variator motors can also depend on factors such as motor size, load characteristics, maintenance practices, and system design. Therefore, it’s advisable to consider specific motor specifications, consult with manufacturers, and conduct energy efficiency assessments to determine the most suitable motor type for a given application.

editor by CX 2024-04-26

China high quality Udl Series Stepless Gearbox Speed Variator and Bevel Gear Speed Reducer with Hot selling

Product Description

|

item |

value |

|

Warranty |

1 year |

|

Applicable Industries |

Manufacturing Plant, Construction works , Energy & Mining, Other |

|

Customized support |

OEM |

|

Gearing Arrangement |

Worm |

|

Place of CHINAMFG |

ZheJiang , China |

|

Input speed |

1500 |

|

Output speed |

1000-2000rpm |

|

Product name |

Udl Variable Speed |

|

MOQ |

10pcs |

|

Color |

Customization |

FAQ

Q1:Are you a manufacturer or trading company?

Yes, We are a leading manufacturer specialized in production of various kinds of small and medium-sized

motor.

Q2:How to choose a gearbox which meets our requirement?

You can refer to our catalogue to choose the gearbox or we can help to choose when you provide

the technical information of required output torque, output speed and motor parameter etc.

Q3:What information shall we give before placing a purchase order?

a) Type of the gearbox, ratio, input and output type, input flange, mounting position, and motor information etc.

b) Housing color.

c) Purchase quantity.

d) Other special requirements.

Q4:What industries are your gearboxes being used?

Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry, escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, logistics and etc.

Q5:How about your delivery time?

For micro brush dc gear motor, the sample delivery time is 2-5 days, bulk delivery time is about 15-20 days, depends on the order qty. For brushless dc motor, the sample deliver time is about 10-15 days; bulk time is 15-20 days.Please take the sales confirmation for final reference.

Q6:What’s your warranty terms?

One year

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | as for Request |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Stepless |

| Samples: |

US$ 65/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What maintenance practices are recommended to ensure the optimal functioning of variator motors?

To ensure the optimal functioning and longevity of variator motors, several maintenance practices are recommended. Here are some key maintenance practices to consider:

- Regular Inspections: Conduct regular visual inspections of the motor to check for any signs of damage, wear, or loose connections. Inspect the motor’s housing, cooling fins, terminal blocks, and cables. Look for any abnormal vibrations, unusual noises, or overheating indications.

- Cleaning: Keep the motor clean by regularly removing dirt, dust, and debris that may accumulate on the motor’s surface or cooling fins. Use compressed air or a soft brush to clean these areas. Avoid using high-pressure water or solvents that could damage the motor’s components.

- Lubrication: If applicable, follow the manufacturer’s recommendations for lubricating the motor. Some variator motors may require periodic lubrication of bearings or other moving parts. Use the specified lubricant and ensure proper lubrication intervals to maintain smooth operation and prevent premature wear.

- Tightening Connections: Check and tighten all electrical and mechanical connections regularly. Loose connections can lead to increased resistance, voltage drops, and overheating. Pay attention to terminal connections, wiring, and grounding connections. Use proper tools and torque values to avoid over-tightening or damaging the connections.

- Condition Monitoring: Implement condition monitoring techniques to detect any early signs of motor degradation or impending failures. This can include monitoring parameters such as temperature, vibration, current, and insulation resistance. Regularly analyze and trend these parameters to identify any deviations from normal operating conditions and take appropriate actions.

- Temperature Monitoring: Continuously monitor the motor’s operating temperature to ensure it remains within the manufacturer’s specified limits. Excessive heat can lead to insulation degradation, bearing failure, and reduced motor life. Use temperature sensors or thermal imaging to monitor and record temperature data during operation.

- Alignment and Balance: Ensure proper alignment and balance of the variator motor and the driven load. Misalignment or imbalance can cause excessive vibrations, increased wear, and premature failures. Follow the manufacturer’s guidelines for alignment procedures and consider using laser alignment tools for precision.

- Protection from Environmental Factors: Protect the variator motor from adverse environmental factors such as excessive moisture, dust, chemicals, or extreme temperatures. If necessary, install appropriate enclosures, seals, or ventilation systems to prevent ingress of contaminants and maintain suitable operating conditions.

- Schedule Maintenance: Develop a schedule for routine maintenance tasks, including inspections, cleaning, lubrication, and any other specific maintenance requirements provided by the manufacturer. Adhere to the maintenance schedule and document all maintenance activities for reference and historical tracking.

- Training and Documentation: Ensure that personnel responsible for the maintenance of variator motors receive proper training on maintenance procedures and safety precautions. Maintain comprehensive documentation, including manuals, maintenance records, and any modifications or repairs performed on the motor.

By following these maintenance practices, you can maximize the performance, reliability, and lifespan of variator motors, reducing the risk of unexpected failures and minimizing downtime.

How do variator motors contribute to energy efficiency in manufacturing processes?

Variator motors play a significant role in improving energy efficiency in manufacturing processes. Here’s a detailed explanation:

Variator motors, also known as variable speed motors or adjustable speed drives, offer the ability to adjust the motor’s speed and torque according to the requirements of the manufacturing process. This flexibility provides several ways in which variator motors contribute to energy efficiency:

- Optimized Process Control: By varying the motor’s speed, variator motors allow manufacturers to precisely match the motor’s output to the process requirements. This optimization eliminates the need for constant full-speed operation, which can result in unnecessary energy consumption. Instead, the motor can run at reduced speeds during periods of lower demand, resulting in energy savings.

- Reduced Mechanical Losses: Traditional motors operating at fixed speeds often use mechanical devices, such as throttling valves or dampers, to control the process flow or pressure. These devices introduce additional mechanical losses that consume energy. With variator motors, the motor speed can be adjusted directly, eliminating the need for such mechanical control devices and reducing energy losses associated with them.

- Efficient Motor Operation: Variator motors are designed to operate efficiently over a broad range of speeds. Unlike fixed-speed motors that may experience reduced efficiency at lower speeds, variator motors can maintain high efficiency even at reduced speeds. This efficiency is achieved through advanced motor designs, improved motor control algorithms, and the use of technologies like permanent magnet motors or synchronous reluctance motors.

- Power Factor Correction: Variator motors can incorporate power factor correction (PFC) techniques to improve the power factor of the motor. Power factor is a measure of how effectively the motor utilizes the supplied electrical power. By improving the power factor, variator motors reduce the reactive power drawn from the power grid, resulting in lower electricity bills and reduced strain on the electrical distribution system.

- Energy Recovery: Some variator motors can feature regenerative capabilities, allowing them to recover and feed excess energy back into the power grid or reuse it within the manufacturing process. For example, in applications where the motor decelerates or operates as a generator, the energy generated can be fed back into the grid or used to power other equipment, further enhancing energy efficiency.

- Process Optimization: Variator motors offer the advantage of precise control over motor speed and torque. This control can be utilized to optimize manufacturing processes, such as matching the motor speed to the optimal speed for material handling, mixing, or other process requirements. By fine-tuning the motor operation, variator motors enable improved process efficiency, reduced material waste, and energy savings.

By leveraging the flexibility and control offered by variator motors, manufacturers can achieve substantial energy savings in their production processes. The specific energy-saving potential will depend on the application, process requirements, and the extent to which the motor’s speed and torque can be optimized. It’s important to consult with motor manufacturers, engineers, and energy experts to assess the suitability and potential energy savings of variator motors in specific manufacturing applications.

What are the advantages of using variator motors in industrial settings?

Variator motors offer several advantages when used in industrial settings. Here are some key benefits:

- Flexible Speed Control: One of the primary advantages of variator motors is their ability to provide flexible speed control. Unlike traditional motors that operate at a fixed speed, variator motors allow for adjustable speed settings. This flexibility enables industrial processes to be optimized for different operational requirements, such as varying loads, different stages of production, or specific process demands.

- Energy Efficiency: Variator motors can help improve energy efficiency in industrial settings. By adjusting the motor speed to match the required output, these motors can avoid the energy losses associated with running at fixed speeds. Operating the motor at lower speeds when the full speed is not necessary can lead to significant energy savings. This energy efficiency not only reduces operational costs but also contributes to sustainability and environmental conservation efforts.

- Precise Process Control: The ability to finely tune the speed of variator motors enables precise process control in industrial settings. Processes that require accurate manipulation of speed, such as mixing, blending, and conveyance, can benefit from variator motors. The adjustable speed allows for better control over product quality, consistency, and production rates.

- Adaptability to Changing Loads: Variator motors are well-suited for applications that experience varying loads. The adjustable speed control allows the motor to respond to changes in load conditions, compensating for fluctuations and ensuring optimal performance. This adaptability is particularly advantageous in industries where load variations are common, such as material handling, conveyor systems, and production lines with varying throughput requirements.

- Reduced Mechanical Stress: In some industrial processes, sudden starts or stops and rapid speed changes can subject mechanical components to excessive stress, leading to premature wear and tear. Variator motors can mitigate this issue by providing smooth and controlled acceleration and deceleration. The ability to gradually ramp up or down the motor speed reduces mechanical stress on the system, prolonging the lifespan of equipment and minimizing maintenance needs.

- Improved Productivity: Variator motors can contribute to improved productivity in industrial settings. The adjustable speed control allows for process optimization, reducing cycle times and enhancing overall efficiency. By matching the motor speed to the specific requirements of each stage of production, variator motors can help streamline operations and increase productivity.

These advantages make variator motors a valuable choice for a wide range of industrial applications. Their flexibility, energy efficiency, precise control, adaptability, and productivity enhancements contribute to improved performance and cost-effectiveness in industrial settings.

editor by CX 2024-04-25

China wholesaler Transmission Geared Motor Unit Screw Drive Lifts Stepper Extruder Helical Planetary Bevel Worm Speed Variator Gear Reducer Gearbox vacuum pump oil near me

Product Description

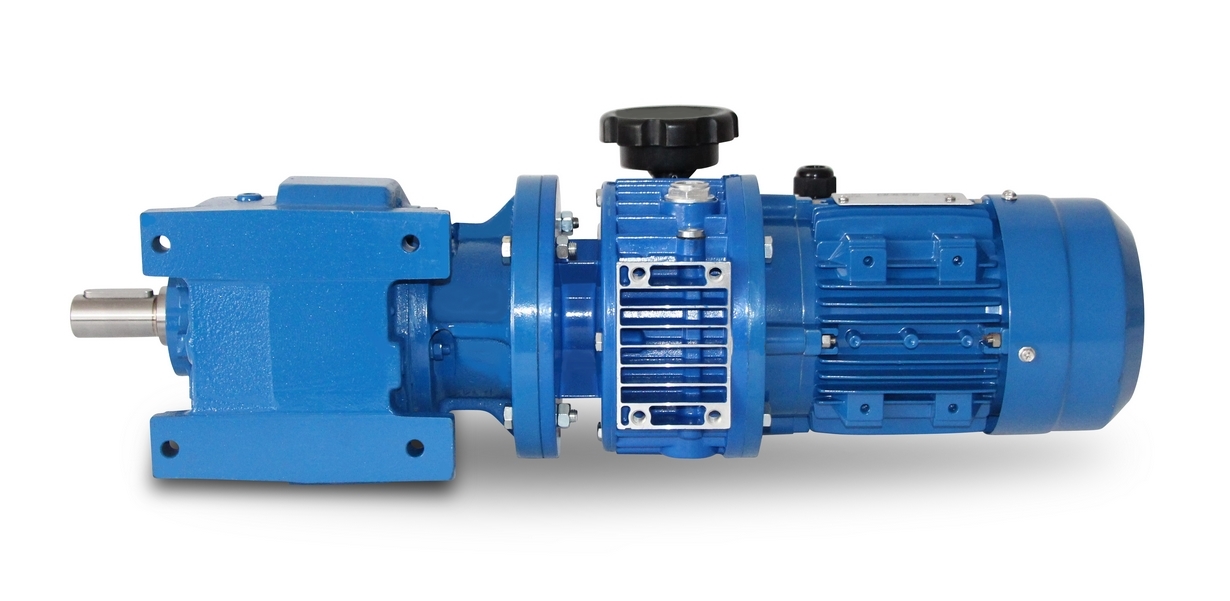

SRC HELICAL GEARBOX

Products Description

We produce speed reducers in strict accordance with ISO9001 standard to provide our customers with high quality gearboxes at competitive prices. Our gearboxes are equipped with accessories from international famous brands, such as lubricant from Shell brand, and bearing from CHINAMFG brand. The housing and gear are produced in our company under stringent quality control. All our products are available in large stocks, and we can also provide you with customized reducer solutions, pleasefeel confident to contact us.

|

TRC: code for gear units series |

|

1. No code means foot-mounted |

|

2.F: B5 flange mounted |

|

3.Z:B14 flange mounted |

|

Specification code of gear units 01,02.03.04 |

|

B01,MO1……means foot code,without flange |

|

1.I.II1.B5 Output flange specification, defaultl not to write out is ok |

|

2. IECinput flange |

|

3.HS: Shaft input |

|

Transmission ratio of gear units |

|

1.M1: Mounting positio, default mounting position M1 not to write out is ok |

|

1.No mark means without motor |

|

2. Model motos (poles of power)voltage – frequency |

|

voltage – frequency |

|

|

|

|

HangZhou CHINAMFG Machinery Co., Ltd.

History: More than 20 years of experience in the manufacture of reducer products.Scale: Cover working area of 13300 square. meters,have more than 113 employees.

Technology: A group of professional . technical engineers and a strong R&D team.

Management: Scientific ERP management and strict quality control system.

Equipment: 50 CNC lathes,6 machining. centers, 6 gear grinding machines, 2 high-speed.hard hobbing machines, 12 gear hobbing

machines. 10 CNC cylindrical grinding machines,4 CNC internal grinding machines 1spectrometer, high-speed gear shaping 1 machine,

2 gear measuring centers 1 coordinate measuring instrument.

lnnovation: Continuously diversify products range to satisfy customers’needs.Production capacity: 1000 pcs/day.

Long-term supplier of world-class companies: t he main markets are in Southea st Asia, Europe, Middle East.

Marketing model: All export business.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Step: | Double-Step |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does the size and power rating of variator motors impact their performance?

The size and power rating of variator motors have a significant impact on their performance. Here’s a detailed explanation of how these factors influence motor performance:

- Torque Output: The size and power rating of a variator motor directly affect its torque output. Generally, larger and higher-rated motors can deliver higher torque levels, allowing them to handle heavier or more demanding loads. A motor with higher torque capability can provide better acceleration, overcome resistance, and maintain stable operation under varying load conditions.

- Speed Range: The size and power rating of the motor also influence its speed range. Motors with higher power ratings can typically achieve a broader speed range, allowing for more flexibility in matching the motor’s speed to the application’s requirements. Smaller motors may have a more limited speed range, which can impact their suitability for certain applications that require a wide range of speeds.

- Overload Capacity: Larger and higher-rated variator motors generally have a higher overload capacity. They can handle temporary increases in load or momentary peak demands without experiencing significant performance degradation or overheating. This makes them suitable for applications with intermittent or cyclical loads, where occasional high torque requirements may arise.

- Efficiency: The size and power rating of a motor can impact its efficiency. In general, larger motors tend to have higher efficiencies, especially when operating near their rated capacity. Higher efficiency means less energy loss as heat and improved overall energy utilization. It’s important to select a motor with an appropriate power rating to ensure efficient operation while avoiding oversized motors that may operate at low efficiency levels.

- Physical Dimensions: The size of a variator motor directly affects its physical dimensions and weight. Larger motors typically have larger physical footprints and may be heavier. The physical dimensions of the motor can impact its installation requirements, space availability, and integration into the overall system design. It’s important to consider the available space and mounting requirements when selecting a motor of a suitable size.

- Heat Dissipation: The size and power rating of a motor influence its heat dissipation capabilities. Higher-rated motors generally generate more heat during operation, and larger motors have a larger surface area for heat dissipation. Adequate heat dissipation is crucial to prevent overheating and ensure the motor’s long-term reliability. It’s important to consider the motor’s cooling requirements, such as ventilation or cooling mechanisms, to maintain optimal operating temperatures.

- Cost: The size and power rating of a variator motor can impact its cost. Generally, larger and higher-rated motors tend to be more expensive than smaller ones due to the increased materials, manufacturing complexity, and performance capabilities. It’s important to balance the motor’s size, power rating, and associated cost with the specific requirements and budget of the application.

In summary, the size and power rating of variator motors significantly influence their performance in terms of torque output, speed range, overload capacity, efficiency, physical dimensions, heat dissipation, and cost. It’s crucial to carefully consider these factors when selecting a motor to ensure it meets the requirements of the application and delivers optimal performance and reliability.

What are the key components and technologies used in modern variator motors?

Modern variator motors incorporate several key components and technologies to enable their variable speed and adjustable torque capabilities. Here’s a detailed explanation:

1. Motor Stator and Rotor: The motor stator and rotor are fundamental components of variator motors. The stator consists of a stationary set of windings that generate a rotating magnetic field when energized. The rotor, typically mounted on the motor shaft, contains conductive bars or coils that interact with the magnetic field and produce mechanical rotation.

2. Power Electronics: Variator motors rely on power electronics components, such as inverters or variable frequency drives (VFDs), to control the motor’s speed and torque. These devices convert the incoming AC power supply into the appropriate voltage and frequency required by the motor. Power electronics also enable smooth and precise adjustment of motor operating parameters, facilitating variable speed operation.

3. Sensors and Feedback Devices: Variator motors often incorporate sensors and feedback devices to monitor motor performance and provide input for control algorithms. Common sensors used include speed sensors, position sensors, temperature sensors, and current sensors. These sensors provide real-time information about the motor’s operating conditions, allowing the control system to adjust motor parameters accordingly.

4. Control Algorithms and Software: Modern variator motors employ sophisticated control algorithms and software to regulate motor speed, torque, and other operating parameters. These algorithms process the sensor data and generate control signals to adjust the power electronics and optimize motor performance. Advanced control techniques, such as field-oriented control (FOC) or model predictive control (MPC), may be used to achieve precise and efficient motor operation.

5. Variable Speed Drive Mechanisms: Variator motors employ various mechanisms to achieve variable speed operation. These mechanisms can include adjustable pulley systems, belt drives, gearboxes, or electronic control of motor winding configurations. The specific mechanism depends on the motor’s design and application requirements.

6. Efficiency-Enhancing Technologies: Modern variator motors incorporate technologies aimed at improving energy efficiency and reducing losses. These technologies may include the use of high-efficiency motor designs, such as permanent magnet motors or synchronous reluctance motors. Additionally, advanced insulation materials, optimized motor cooling systems, and reduced friction bearings can contribute to enhanced motor efficiency.

7. Communication and Networking: Some variator motors feature communication and networking capabilities to enable integration with industrial automation systems or the Internet of Things (IoT). These capabilities facilitate remote monitoring, control, and data exchange, allowing for enhanced motor performance analysis, predictive maintenance, and system integration.

8. Safety and Protection Features: Modern variator motors incorporate safety and protection features to safeguard the motor and the surrounding equipment. These features may include overcurrent protection, overvoltage protection, short-circuit protection, thermal protection, and fault detection mechanisms. These measures ensure safe and reliable operation and help prevent damage to the motor in case of abnormal operating conditions.

The specific components and technologies used in variator motors can vary depending on the motor’s type, design, and application requirements. Motor manufacturers continuously innovate and incorporate advancements in materials, electronics, and control systems to improve motor performance, efficiency, and reliability.

What are the advantages of using variator motors in industrial settings?

Variator motors offer several advantages when used in industrial settings. Here are some key benefits:

- Flexible Speed Control: One of the primary advantages of variator motors is their ability to provide flexible speed control. Unlike traditional motors that operate at a fixed speed, variator motors allow for adjustable speed settings. This flexibility enables industrial processes to be optimized for different operational requirements, such as varying loads, different stages of production, or specific process demands.

- Energy Efficiency: Variator motors can help improve energy efficiency in industrial settings. By adjusting the motor speed to match the required output, these motors can avoid the energy losses associated with running at fixed speeds. Operating the motor at lower speeds when the full speed is not necessary can lead to significant energy savings. This energy efficiency not only reduces operational costs but also contributes to sustainability and environmental conservation efforts.

- Precise Process Control: The ability to finely tune the speed of variator motors enables precise process control in industrial settings. Processes that require accurate manipulation of speed, such as mixing, blending, and conveyance, can benefit from variator motors. The adjustable speed allows for better control over product quality, consistency, and production rates.

- Adaptability to Changing Loads: Variator motors are well-suited for applications that experience varying loads. The adjustable speed control allows the motor to respond to changes in load conditions, compensating for fluctuations and ensuring optimal performance. This adaptability is particularly advantageous in industries where load variations are common, such as material handling, conveyor systems, and production lines with varying throughput requirements.

- Reduced Mechanical Stress: In some industrial processes, sudden starts or stops and rapid speed changes can subject mechanical components to excessive stress, leading to premature wear and tear. Variator motors can mitigate this issue by providing smooth and controlled acceleration and deceleration. The ability to gradually ramp up or down the motor speed reduces mechanical stress on the system, prolonging the lifespan of equipment and minimizing maintenance needs.

- Improved Productivity: Variator motors can contribute to improved productivity in industrial settings. The adjustable speed control allows for process optimization, reducing cycle times and enhancing overall efficiency. By matching the motor speed to the specific requirements of each stage of production, variator motors can help streamline operations and increase productivity.

These advantages make variator motors a valuable choice for a wide range of industrial applications. Their flexibility, energy efficiency, precise control, adaptability, and productivity enhancements contribute to improved performance and cost-effectiveness in industrial settings.

editor by CX 2024-04-24

China best Worm Gear Box Assembly Gearbox Wheel Speed Reducer Jack Worm Agricultural Planetary Helical Bevel Steering Gear Drive Motor Speed Nmrv Good Quantity Durable wholesaler

Product Description

Technical Features

The high degree of modularity is a design feature of SRC helical gearboxes range. It can be connected respectively with motors such as normal motor, brake motor, explosion-proof motor, frequency conversion motor, servo motor, IEC motor and so on. This kind of product is widely used in drive fields such as textile, foodstuff, ceramics packing, logistics, plastics and so on. It is possible to set up the version required using flanges or feet.

Products characteristics

SRC series helical gear units has more than 4 types. Power 0.12-4kw; Ratio 3.66-54; Torque max 120-500Nm. It can be connected (foot or flange) discretionary and use multi-mounting positions according to customers requirements.

Ground-hardened helical gears;

Modularity,can be combined in many forms;

Aluminium casing, light weight;

Gears in carbonize hard, durable;

Universal mounting;

Refined design,space effective and low noise

Structure feature

Model illuminate

|

1 |

Code for gear units series |

|

2 |

No F code means foot mounted.With F code B5 flange mounted.With Z code B14 flange mounted |

|

3 |

Specification code of gear units 01 |

|

4 |

I,II,III,B5 Output flange specification,default I not to write out is ok |

|

5 |

IEC: Input flange HS: shaft input |

|

6 |

Transmission ratio of gear units |

|

7 |

M1:Mounting position, default mounting position M1 not to write out is ok |

|

8 |

Position diagram for motor terminal box,default position o°(R) not to write out is ok |

|

9 |

No mark means without motor Model motor(poles of power) |

|

10 |

Voltage – frequency |

|

11 |

Coil in position for motor, default position S not to write out is ok |

4.2 Rotation speed n

n1 Gear units input speed

n2 Gear units output speed

If driven by the external gearing,1400r/min or lower rotation speed is suggested so as to optimize the working conditions and prolong the service life.Higher input rotation speed is permitted, but in this situation,the rated torque M2 will be reduced

4.5 Service factor fs

The effect of the driven machine on the gear unit is taken into account to a sufficient level of accuracy using the service factor fs. The service factor is determined according to the daily operation time and the starting frequency Z. Three load classifications are considered depending on the mass acceleration factor. You can read off the service factor applicable to your application in following figure. The service factor selected using this diagram must be less than or equal to the service factor as given in the performance parameter table.

* starting frequency Z: The cycles include all starting and braking procedures as well as change overs from low to high speed

SRC02..(HS) Performance parameter

|

kw |

Output speed |

Torque |

Speed ratio |

fs |

Model |

IEC |

|

0.37 |

16.7rpm |

204N.M |

54 |

1.0 |

SRC02 |

80B5/B14

|

Helical gearbox outline dimension heet

| Foot Code | U | V | V1 | V2 | V3 | W | X | X1 | Y | Z |

| B02 | 18 | 107.5 | 60 | – | 130 | 11 | 136 | 155 | 100 | 17 |

| M02 | 25 | 85 | – | 110 | 120 | 9 | 112 | 145 | 80 | 15 |

| M01 | 18 | 80 | – | 110 | 120 | 9 | 118 | 145 | 80 | 15 |

| B01 | 18 | 87 | 50 | 110 | – | 9 | 118 | 130 | 90 | 15 |

SRC helical gearbox with motor mounting position and terminal box orientation

Package

1 pc / carton,several cartons / wooden pallet

| Application: | Motor |

|---|---|

| Layout: | Cycloidal |

| Hardness: | Soft Tooth Surface |

| Installation: | Vertical Type |

| Step: | Stepless |

| Type: | Worm Gear Box |

| Customization: |

Available

| Customized Request |

|---|

The Basics of a Planetary Motor

A Planetary Motor is a type of gearmotor that uses multiple planetary gears to deliver torque. This system minimizes the chances of failure of individual gears and increases output capacity. Compared to the planetary motor, the spur gear motor is less complex and less expensive. However, a spur gear motor is generally more suitable for applications requiring low torque. This is because each gear is responsible for the entire load, limiting its torque.

Self-centering planetary gears

This self-centering mechanism for a planetary motor is based on a helical arrangement. The helical structure involves a sun-planet, with its crown and slope modified. The gears are mounted on a ring and share the load evenly. The helical arrangement can be either self-centering or self-resonant. This method is suited for both applications.

A helical planetary gear transmission is illustrated in FIG. 1. A helical configuration includes an output shaft 18 and a sun gear 18. The drive shaft extends through an opening in the cover to engage drive pins on the planet carriers. The drive shaft of the planetary gears can be fixed to the helical arrangement or can be removable. The transmission system is symmetrical, allowing the output shaft of the planetary motor to rotate radially in response to the forces acting on the planet gears.

A flexible pin can improve load sharing. This modification may decrease the face load distribution, but increases the (K_Hbeta) parameter. This effect affects the gear rating and life. It is important to understand the effects of flexible pins. It is worth noting that there are several other disadvantages of flexible pins in helical PGSs. The benefits of flexible pins are discussed below.

Using self-centering planetary gears for a helical planetary motor is essential for symmetrical force distribution. These gears ensure the symmetry of force distribution. They can also be used for self-centering applications. Self-centering planetary gears also guarantee the proper force distribution. They are used to drive a planetary motor. The gearhead is made of a ring gear, and the output shaft is supported by two ball bearings. Self-centering planetary gears can handle a high torque input, and can be suited for many applications.

To solve for a planetary gear mechanism, you need to find its pitch curve. The first step is to find the radius of the internal gear ring. A noncircular planetary gear mechanism should be able to satisfy constraints that can be complex and nonlinear. Using a computer, you can solve for these constraints by analyzing the profile of the planetary wheel’s tooth curve.

High torque

Compared to the conventional planetary motors, high-torque planetary motors have a higher output torque and better transmission efficiency. The high-torque planetary motors are designed to withstand large loads and are used in many types of applications, such as medical equipment and miniature consumer electronics. Their compact design makes them suitable for small space-saving applications. In addition, these motors are designed for high-speed operation.

They come with a variety of shaft configurations and have a wide range of price-performance ratios. The FAULHABER planetary gearboxes are made of plastic, resulting in a good price-performance ratio. In addition, plastic input stage gears are used in applications requiring high torques, and steel input stage gears are available for higher speeds. For difficult operating conditions, modified lubrication is available.

Various planetary gear motors are available in different sizes and power levels. Generally, planetary gear motors are made of steel, brass, or plastic, though some use plastic for their gears. Steel-cut gears are the most durable, and are ideal for applications that require a high amount of torque. Similarly, nickel-steel gears are more lubricated and can withstand a high amount of wear.

The output torque of a high-torque planetary gearbox depends on its rated input speed. Industrial-grade high-torque planetary gearboxes are capable of up to 18000 RPM. Their output torque is not higher than 2000 nm. They are also used in machines where a planet is decelerating. Their working temperature ranges between 25 and 100 degrees Celsius. For best results, it is best to choose the right size for the application.

A high-torque planetary gearbox is the most suitable type of high-torque planetary motor. It is important to determine the deceleration ratio before buying one. If there is no product catalog that matches your servo motor, consider buying a close-fitting high-torque planetary gearbox. There are also high-torque planetary gearboxes available for custom-made applications.

High efficiency

A planetary gearbox is a type of mechanical device that is used for high-torque transmission. This gearbox is made of multiple pairs of gears. Large gears on the output shaft mesh with small gears on the input shaft. The ratio between the big and small gear teeth determines the transmittable torque. High-efficiency planetary gearheads are available for linear motion, axial loads, and sterilizable applications.

The AG2400 high-end gear unit series is ideally matched to Beckhoff’s extensive line of servomotors and gearboxes. Its single-stage and multi-stage transmission ratios are highly flexible and can be matched to different robot types. Its modified lubrication helps it operate in difficult operating conditions. These high-performance gear units are available in a wide range of sizes.

A planetary gear motor can be made of steel, nickel-steel, or brass. In addition to steel, some models use plastic. The planetary gears share work between multiple gears, making it easy to transfer high amounts of power without putting a lot of stress on the gears. The gears in a planetary gear motor are held together by a movable arm. High-efficiency planetary gear motors are more efficient than traditional gearmotors.

While a planetary gear motor can generate torque, it is more efficient and cheaper to produce. The planetary gear system is designed with all gears operating in synchrony, minimizing the chance of a single gear failure. The efficiency of a planetary gearmotor makes it a popular choice for high-torque applications. This type of motor is suitable for many applications, and is less expensive than a standard geared motor.

The planetary gearbox is a combination of a planetary type gearbox and a DC motor. The planetary gearbox is compact, versatile, and efficient, and can be used in a wide range of industrial environments. The planetary gearbox with an HN210 DC motor is used in a 22mm OD, PPH, and ph configuration with voltage operating between 6V and 24V. It is available in many configurations and can be custom-made to meet your application requirements.

High cost

In general, planetary gearmotors are more expensive than other configurations of gearmotors. This is due to the complexity of their design, which involves the use of a central sun gear and a set of planetary gears which mesh with each other. The entire assembly is enclosed in a larger internal tooth gear. However, planetary motors are more effective for higher load requirements. The cost of planetary motors varies depending on the number of gears and the number of planetary gears in the system.

If you want to build a planetary gearbox, you can purchase a gearbox for the motor. These gearboxes are often available with several ratios, and you can use any one to create a custom ratio. The cost of a gearbox depends on how much power you want to move with the gearbox, and how much gear ratio you need. You can even contact your local FRC team to purchase a gearbox for the motor.

Gearboxes play a major role in determining the efficiency of a planetary gearmotor. The output shafts used for this type of motor are usually made of steel or nickel-steel, while those used in planetary gearboxes are made from brass or plastic. The former is the most durable and is best for applications that require high torque. The latter, however, is more absorbent and is better at holding lubricant.

Using a planetary gearbox will allow you to reduce the input power required for the stepper motor. However, this is not without its downsides. A planetary gearbox can also be replaced with a spare part. A planetary gearbox is inexpensive, and its spare parts are inexpensive. A planetary gearbox has low cost compared to a planetary motor. Its advantages make it more desirable in certain applications.

Another advantage of a planetary gear unit is the ability to handle ultra-low speeds. Using a planetary gearbox allows stepper motors to avoid resonance zones, which can cause them to crawl. In addition, the planetary gear unit allows for safe and efficient cleaning. So, whether you’re considering a planetary gear unit for a particular application, these gear units can help you get exactly what you need.

editor by CX 2023-05-09

china near me Snkg Bevel Helical Gearbox with Permanent Magnet Synchronous Motor Integrate Variable Frequency Drive manufacturers

Product Description

SNKGA200A-MD100C Bevel CZPT cal gearbox with Everlasting magnet synchronous motor combine variable frequency driver for conveyor

SNKG Collection prorduct adopt harden teeth surface bevel gear and CZPT cal equipment to travel, following the design basic principle of modularization , FEA analyse technology, distinctive minimal-noise equipment tooth profile, with the characteristics of compact quantity, high load functionality and steady operating, dependability and CZPT support daily life.

Essential positive aspects

-Easy wiring, minimal expense

-Massive amount of knowledge, CZPT velocity, 100m, data transmission is 500K

-All handle models have the exact same issue, it signifies every single node has the very same legal rights to occupy the bus (deliver and receive)

-Communication fee meets manage requirements, communication info amount supports required knowledge looking through.

-Electrical eye and proximity change sensor offer sign to the driver immediately, it is convenient and reliable.

ABOUT US

ZheJiang CZPT shine CZPT Co.,Ltd(Starshine) have a sturdy technological force with in excess of 350 workers at present, which includes in excess of 30 CZPT professionals, 30 top quality inspectors, masking an region of 80000 square meters and sorts of CZPT d processing devices and testing equipments. We have a very good basis for the market software advancement and provider of substantial-stop speed reducers & variators possessing to the provincial CZPT technological innovation study heart,the lab of gear pace reducers, and the base of modern day R&D.

Our products are extensively employed in ceramic business, glass business, woodworking machinery , high voltage switch, foods & beverage, packaging & printing, Storage & logistics, hoisting & transportation facilities…etc , and CZPT glow technically give the professional solution & provider for the medium and high-end CZPT ers, and CZPT gearboxes are very best-promoting in domestic, and even in overseas , these kinds of as in CZPT pe, North CZPT ica, South CZPT ica, Middle CZPT , South Asia, CZPT Asia, Africa…etc.

In the potential , CZPT glow will keep the creed of “serving CZPT er, diligence & simplicity, self-criticism, innovation, honesty, teamwork”, and the notion of “high quality generates value” to concentrate on the CZPT ers’ demands and give them the aggressive transmission resolution and produce worth for them constantly, and make a large-stop tools production business and develop a favored model of replacing import items and upgrading continually for the finish customers.

OUR TEAM

Top quality Handle

Good quality:Insist on Advancement,Try for CZPT With the advancement of products production indurstry,buyer in no way satirsfy with the existing quality of CZPT products,on the contrary,wcreate the worth of high quality.

Top quality coverage:to improve the general amount in the field of CZPT transmission

Top quality See:Constant Enhancement , pursuit of excellence

High quality Philosophy:Good quality creates price

3. Incoming Quality Management

To create the AQL acceptable stage of incoming content control, to supply the substance for the total inspection, sampling, immunity. On the acceptance of experienced products to warehousing, substandard merchandise to consider return, examine, rework, rework inspection responsible for tracking poor, to check the supplier to consider corrective measures to avert recurrence.

four. Procedure Good quality Manage

The production website of the 1st assessment, inspection and closing inspection, sampling in accordance to the needs of some assignments, judging the quality change pattern discovered abnormal phenomenon of producing, and supervise the generation department to increase, get rid of the abnormal phenomenon or point out.

5. FQC(Final QC)

Following the manufacturing division will complete the item, stand in the CZPT er’s place on the concluded merchandise top quality verification, in order to ensure the quality of CZPT er expectations and wants.

six. OQC(Outgoing QC)

After the product sample inspection to establish the experienced, allowing storage, but when the completed product from the warehouse just before the formal shipping of the goods, there is a check, this is named the shipment inspection.Check articles:In the warehouse storage and transfer status to validate, while confirming the supply of the product is a item inspection to decide the qualified goods.

PACKING

Supply

AC motors vary from several other kinds of motors, specifically some of the much more acquainted DC (immediate existing) motors, by several critical conditions. The most fundamental of these is the fact that an AC motor relies fully on the alternating recent about its circuit to create effective mechanical strength. We will talk about this exclusive process in more depth in the adhering to sections of this information.

china price K Series Right Angle Spiral Bevel Gearbox with Output Solid Shaft manufacturers

Item Description

Starshine CZPT K Sequence CZPT cal -Bevel Geared CZPT

Characteristics:

-High efficiency: ninety two%-ninety three%

-Vertical output, compact construction, hard tooth floor , huge output torque, minimal noise and long support daily life.

-Substantial precision: the gear is made of substantial-top quality alloy steel forging, carbonitriding and hardening remedy, grinding method to make sure large precision and secure working.

-Higher interchangeability: hugely modular, serial style, sturdy flexibility and interchangeability.

Technological parameters

| Ratio | 5.36-197.37 |

| Enter CZPT | .twelve-200KW |

| Output torque | 10-62800N.m |

| Output speed | 7-415rpm |

| Mounting kind | Foot mounted, foot mounted with strong shaft, output flange mounted, hollow shaft mounted, B5 flange mounted with hollow shaft, foot mounted with hollow shaft, B14 flange mounted with hollow shaft, foot mounted with splined gap, foot mounted with shrink disk, hollow shaft mounted with anti-torque arm. |

| Input Technique | Flange enter(AM), shaft enter(Advertisement), inline AC motor enter, or AQA servo motor |

| Brake Release | HF-handbook release(lock in the brake release situation), HR-guide launch(autom-atic braking situation) |

| Thermistor | TF(Thermistor security PTC thermisto) TH(Thermistor safety Bimetal swotch) |

ABOUT STARSHINE Generate

ZheJiang CZPT glow CZPT Co.,Ltd(Starshine) have a powerful technical power with over 350 employees at existing, like over 30 CZPT experts, 30 high quality inspectors, masking an area of 80000 square meters and types of CZPT d processing devices and testing equipments. We have a great basis for the business application improvement and provider of large-end speed reducers & variators owning to the provincial CZPT technology research center,the lab of equipment pace reducers, and the base of modern day R&D.

Our products are widely utilised in ceramic market, glass sector, woodworking equipment , substantial voltage swap, meals & beverage, packaging & printing, Storage & logistics, hoisting & transportation facilities…etc , and CZPT shine technically supply the professional product & service for the medium and substantial-stop CZPT ers, and CZPT gearboxes are very best-offering in domestic, and even in abroad , these kinds of as in CZPT pe, North CZPT ica, South CZPT ica, Middle CZPT , South Asia, CZPT Asia, Africa…etc.

In the potential , CZPT shine will keep the creed of “serving CZPT er, diligence & simplicity, self-criticism, innovation, honesty, teamwork”, and the principle of “quality creates benefit” to concentrate on the CZPT ers’ demands and offer them the competitive transmission resolution and create price for them consistently, and make a large-stop tools manufacturing industry and create a preferred model of replacing import products and upgrading repeatedly for the finish customers.

Team

Good quality Control

High quality:Insist on Improvement,Try for CZPT With the growth of tools producing indurstry,customer in no way satirsfy with the existing quality of CZPT products,on the contrary,wcreate the worth of top quality.

High quality plan:to enhance the total amount in the discipline of CZPT transmission

Good quality View:Continuous Improvement , pursuit of excellence

High quality Philosophy:Quality creates worth

3. Incoming Quality Handle

To establish the AQL satisfactory level of incoming content control, to provide the content for the total inspection, sampling, immunity. On the acceptance of competent products to warehousing, substandard products to just take return, check out, rework, rework inspection liable for tracking negative, to keep an eye on the supplier to consider corrective actions to avoid recurrence.

4. Process Good quality Manage

The producing site of the very first assessment, inspection and closing inspection, sampling according to the requirements of some assignments, judging the quality change pattern found irregular phenomenon of production, and supervise the manufacturing division to improve, remove the irregular phenomenon or point out

5. FQC(Final QC)

Following the production division will complete the solution, stand in the CZPT er’s situation on the completed product good quality verification, in order to ensure the good quality of CZPT er anticipations and demands.

6. OQC(Outgoing QC)

Right after the item sample inspection to establish the certified, allowing storage, but when the concluded product from the warehouse ahead of the formal shipping of the products, there is a examine, this is referred to as the shipment inspection.Check content:In the warehouse storage and transfer standing to affirm, while confirming the shipping of the solution is a item inspection to figure out the competent merchandise.

PACKING

DELIVERY

DC motors use energy from batteries or other creating resources that provide a consistent voltage. A DC motor is composed of numerous elements, the most well-known of which include bearings, shafts, and gearboxes or gears. DC motors offer greater pace variation and manage and produce a lot more torque than AC motors. The two kinds of DC motors include Brushed motors: Brushed motors are a single of the oldest varieties and are internally commutated motors pushed by DC current. A brushed motor is made up of a rotor, brushes, and a shaft. The charge and polarity of the brushes manage the route and pace of the motor. Brushless Motors: In current several years, brushless motors have grow to be common for several apps, mostly simply because of their effectiveness. Brushless motors are created in the exact same way as brushed motors, minus the brushes of system. Brushless motors also include devoted circuitry to management pace and route. In brushless motors, magnets are mounted close to the rotor, an effectiveness-boosting configuration.

china sales High Transmission Efficiency K Series Helical Bevel Gearbox manufacturers

Merchandise Description

High Transmission Efficiency K Series CZPT cal Bevel Gearbox

Description: K Sequence CZPT cal Bevel Gearbox

Overview