Product Description

Product Name:

0.18kw-5600kw 3 Phase AC Squirrel Cage Induction Asynchronous Electric Motor

Product Range:

| Single Phase Induction Motor | 0.12kw~7.5kw |

| Three Phase Induction Motor | 0.18kw~5600kw |

| Slip Ring Induction Motor | 4kw~5600kw |

| Explosion Proof Motor | 0.25kw~1600kw |

| Brake Motor | 0.12kw~200kw |

| DC Motor | 1kw~1500kw |

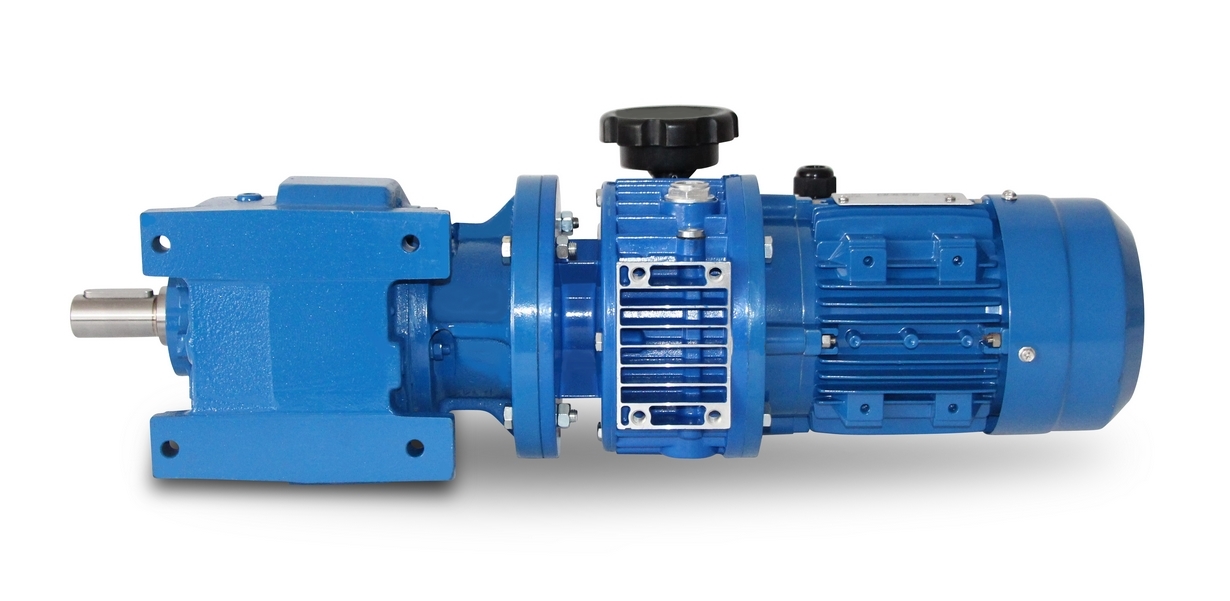

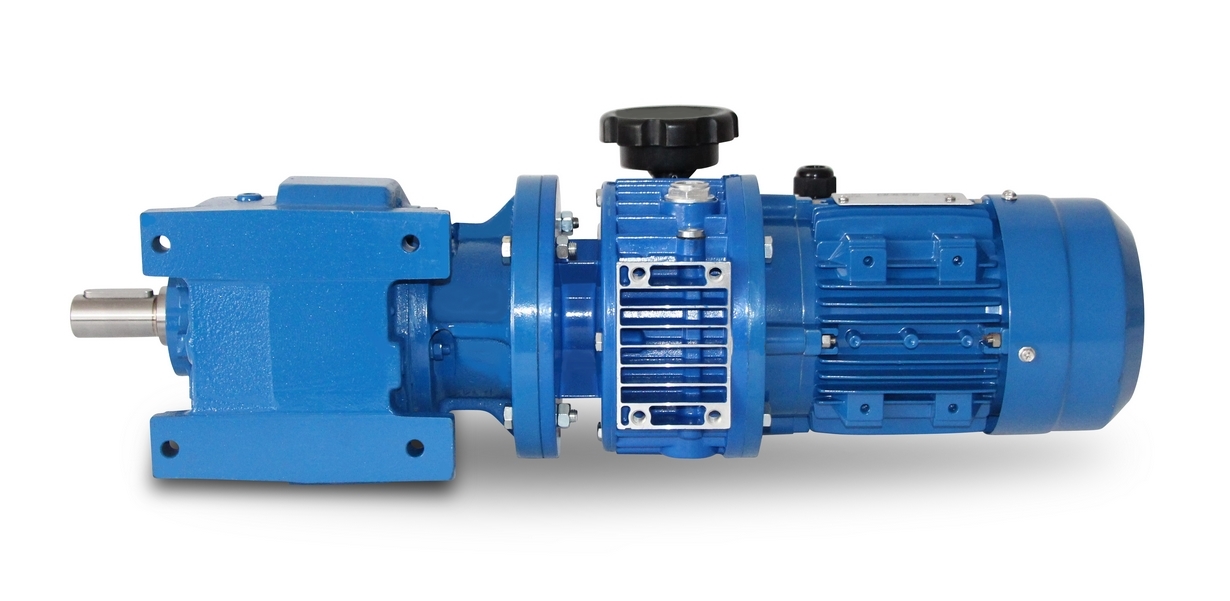

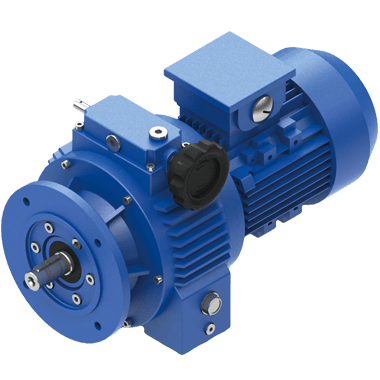

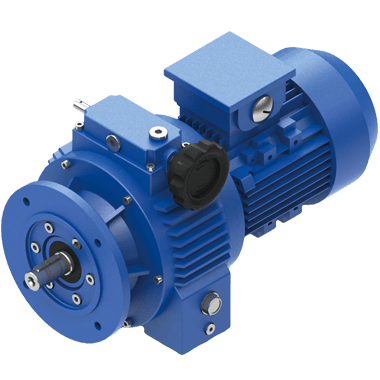

ZheJiang LANGRUI INDUSTRIAL CO., LTD. is reliable electric motor manufacturers and electric motor suppliers. We supply single phase induction motor, 3 phase induction motor, squirrel cage induction motor, slip ring induction motor, wound rotor induction motor, explosion proof motor, ac motor, dc motor, variable speed electric motor, asynchronous motor, synchronous motor, customized electric motors, gearbox, gear motor, speed reducers for decades in China.

We are authorized by ISO9001:2008 as the rules and laws of company operating management.

We includes motors R&D, manufacturing, quality control, technical supporting, domestic and overseas sales, pre-sales and after-sales service etc.

We have winned CHINAMFG reputation from German, UK, Poland, Switzerland, Sweden, Greece, Russia, Ukraine, Uzbekistan, Egypt, Libya, U.A.E., Pakistan, Vietnam, Indonesia, Thailand, Malaysia, Mexico, Cuba, Columbia, other countries and areas.

We are major in manufacturing and supplying general AC motors – single phase induction motors, general asynchronous motors – 3 phase induction motors, explosion proof motors, variable-pole motors, multi speed induction motors, variable frequency motors, variable speed electric motors, brake motors, Russia GOST motors, NEMA motors, high power motors (up to 4000 kW), high voltage motors (up to 13.8 kV), customized motors, helical gear motors, worm gearboxes, planetary gear reducers, speed variators, hanging gear reducers, industrial geared motors and others.

Our motors are widely used in pumps, air blowers, fans, ventilators, mixer, crushers, gearbox, gear motor, reducer, compressors, agitators, refrigerators, conveyors, grinders, elevators, cranes, mills, machine tools, food machinery, press machinery, transportation machinery, agriculture machinery, brick making machinery, textile machinery, mining machinery, paper making machinery, metallurgy machinery, rubber making machinery, petroleum machinery, medicine making machinery, packing machinery, woodworking machinery, chemical machinery, construction machinery, cement making machinery, forging machinery, foundry machinery, hydraulic machinery, pellet machinery, plastic machinery, power plant, steel industry, water conservancy syestem, waste water treatment, dredgers, metal working mills, cooling towers, cableways, petroleum industry, and many other machinery and industries.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Number of Stator: | Three-Phase |

| Function: | Driving |

| Casing Protection: | Closed Type |

| Starting Mode: | Direct on-line Starting |

| Certification: | ISO9001, CCC, CE |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Are variator motors suitable for applications requiring precise speed control?

Yes, variator motors are generally suitable for applications requiring precise speed control. Here’s a detailed explanation:

Variator motors, also known as variable speed motors or adjustable speed motors, are designed to provide adjustable speed control over a wide range. They allow the user to vary the motor’s speed according to the specific requirements of the application. This flexibility makes them well-suited for applications that demand precise speed control.

Here are some reasons why variator motors are suitable for applications requiring precise speed control:

- Speed Adjustment Range: Variator motors offer a wide range of adjustable speeds, allowing for precise control over the motor’s rotational speed. Depending on the specific model and type of variator motor, the speed adjustment range can vary from a few RPM (Revolutions Per Minute) to thousands of RPM. This versatility enables the motor to operate at different speeds, accommodating varying process or load requirements.

- Smooth Speed Transitions: Variator motors can provide smooth and gradual speed transitions. They offer precise speed control without sudden jolts or jerks during acceleration or deceleration. This feature is especially important in applications where precise speed control is critical for maintaining product quality, preventing damage to sensitive equipment, or ensuring smooth operation of processes.

- Speed Accuracy and Stability: Variator motors can achieve high speed accuracy and stability. They can maintain the desired speed setting within tight tolerances, minimizing deviations and fluctuations. This level of control is essential in applications that require precise synchronization, coordination with other system components, or adherence to specific speed profiles.

- Control Options: Variator motors often come with various control options, allowing for precise speed adjustments. These options can include manual control through potentiometers or dials, digital control through interface panels or keypads, or even programmable control through communication protocols such as Modbus or Ethernet. The availability of different control options enhances the motor’s suitability for applications requiring precise speed control.

- Response Time: Variator motors can typically achieve fast response times when adjusting the speed. They can quickly respond to speed commands or changes in the control signal, allowing for precise and immediate adjustments. This responsiveness is beneficial in applications where rapid speed changes or dynamic response is required to meet changing operational conditions.

- Closed-Loop Control Capability: Some variator motors are equipped with closed-loop control capabilities. Closed-loop control involves using feedback sensors, such as encoders or tachometers, to continuously monitor the motor’s actual speed and compare it to the desired speed. The control system adjusts the motor’s speed based on this feedback, ensuring precise speed control and compensating for any variations or disturbances.

- Application Versatility: Variator motors are versatile and can be used in a wide range of applications requiring precise speed control. They find applications in industries such as manufacturing, automation, robotics, HVAC (heating, ventilation, and air conditioning), conveyors, pumps, fans, and many others.

However, it’s important to note that the suitability of variator motors for precise speed control may vary depending on factors such as the specific motor model, control system, and the desired level of precision. It’s recommended to consult the motor manufacturer or an expert in motor control to determine the best solution for a particular application.

What are the key components and technologies used in modern variator motors?

Modern variator motors incorporate several key components and technologies to enable their variable speed and adjustable torque capabilities. Here’s a detailed explanation:

1. Motor Stator and Rotor: The motor stator and rotor are fundamental components of variator motors. The stator consists of a stationary set of windings that generate a rotating magnetic field when energized. The rotor, typically mounted on the motor shaft, contains conductive bars or coils that interact with the magnetic field and produce mechanical rotation.

2. Power Electronics: Variator motors rely on power electronics components, such as inverters or variable frequency drives (VFDs), to control the motor’s speed and torque. These devices convert the incoming AC power supply into the appropriate voltage and frequency required by the motor. Power electronics also enable smooth and precise adjustment of motor operating parameters, facilitating variable speed operation.

3. Sensors and Feedback Devices: Variator motors often incorporate sensors and feedback devices to monitor motor performance and provide input for control algorithms. Common sensors used include speed sensors, position sensors, temperature sensors, and current sensors. These sensors provide real-time information about the motor’s operating conditions, allowing the control system to adjust motor parameters accordingly.

4. Control Algorithms and Software: Modern variator motors employ sophisticated control algorithms and software to regulate motor speed, torque, and other operating parameters. These algorithms process the sensor data and generate control signals to adjust the power electronics and optimize motor performance. Advanced control techniques, such as field-oriented control (FOC) or model predictive control (MPC), may be used to achieve precise and efficient motor operation.

5. Variable Speed Drive Mechanisms: Variator motors employ various mechanisms to achieve variable speed operation. These mechanisms can include adjustable pulley systems, belt drives, gearboxes, or electronic control of motor winding configurations. The specific mechanism depends on the motor’s design and application requirements.

6. Efficiency-Enhancing Technologies: Modern variator motors incorporate technologies aimed at improving energy efficiency and reducing losses. These technologies may include the use of high-efficiency motor designs, such as permanent magnet motors or synchronous reluctance motors. Additionally, advanced insulation materials, optimized motor cooling systems, and reduced friction bearings can contribute to enhanced motor efficiency.

7. Communication and Networking: Some variator motors feature communication and networking capabilities to enable integration with industrial automation systems or the Internet of Things (IoT). These capabilities facilitate remote monitoring, control, and data exchange, allowing for enhanced motor performance analysis, predictive maintenance, and system integration.

8. Safety and Protection Features: Modern variator motors incorporate safety and protection features to safeguard the motor and the surrounding equipment. These features may include overcurrent protection, overvoltage protection, short-circuit protection, thermal protection, and fault detection mechanisms. These measures ensure safe and reliable operation and help prevent damage to the motor in case of abnormal operating conditions.

The specific components and technologies used in variator motors can vary depending on the motor’s type, design, and application requirements. Motor manufacturers continuously innovate and incorporate advancements in materials, electronics, and control systems to improve motor performance, efficiency, and reliability.

How does the efficiency of variator motors compare to other types of motors?

The efficiency of variator motors can vary depending on the specific design, application, and operating conditions. However, in general, variator motors can offer comparable or even higher efficiency compared to other types of motors. Here are some key points to consider:

- Variable Speed Operation: Variator motors excel in variable speed operations where the motor speed can be adjusted to match the load and process requirements. By running the motor at a speed that precisely meets the demand, variator motors can significantly reduce energy losses associated with running at fixed speeds. This level of control contributes to high overall system efficiency.

- Energy Savings through Speed Control: The ability to adjust the motor speed in variator motors allows for energy savings. By operating the motor at lower speeds when full speed is not required, variator motors can achieve energy efficiency gains. This is particularly relevant in applications with varying loads or processes that do not constantly require maximum speed.

- Improved Power Factor: Variator motors with adjustable speed control, such as those incorporating variable frequency drives (VFDs), can improve the power factor of the motor system. Power factor is a measure of how effectively electrical power is being used. By optimizing the motor speed and voltage, VFDs can improve the power factor, resulting in reduced reactive power consumption and improved energy efficiency.

- Motor Design and Technology: The efficiency of variator motors can also be influenced by the motor design and the use of advanced technologies. Manufacturers are continually improving motor designs, incorporating high-quality materials, precision manufacturing techniques, and efficient cooling systems to enhance motor efficiency. Additionally, advancements in motor technologies, such as the use of permanent magnet materials and improved motor control algorithms, contribute to higher overall efficiency.

- Comparison with Other Motor Types: When compared to traditional fixed-speed motors, variator motors generally offer higher efficiency due to their ability to adjust speed according to the load. In applications where variable speed control is required, variator motors can outperform fixed-speed motors in terms of energy savings, precise control, and overall system efficiency.

It’s important to note that the efficiency of variator motors can also depend on factors such as motor size, load characteristics, maintenance practices, and system design. Therefore, it’s advisable to consider specific motor specifications, consult with manufacturers, and conduct energy efficiency assessments to determine the most suitable motor type for a given application.

editor by CX 2024-05-06

China Standard Mini Small Size 2.2kw, 3pH 380V for 3 Phase Motor Customized OEM / ODM with high quality

Product Description

Product Description:

H300 series simple inverter has a wide range of speed regulation,high accuracy, fast dynamic response, high operating efficiency, easy to operate and a series of advantages, mainly used in textile machinery, machine equipment, fan, pump load and other occasions.

Power class: 220V 1PH ,0.4-2.2KW

380V 3PH ,0.75-5.5KW

Name plate :

Product Features:

Multiple protection features:

H300 Series Model:

H300 Series Techinical Standard:

| Item | Specifications | ||

| Basic Functions | Control system | Current Vector General Purpose Inverter. | |

| Compatible motor | Induction motors. | ||

| Maximum frequency | Vector control: 0~500Hz; V/F control: 0~500Hz. |

||

| Carrier frequency | 0.8kHz~12kHz; Depending on load, can automatically adjust. | ||

| Input resolution | Digital: 0.01Hz; | Analog: maximum frequency×0.1%. | |

| Control modes | Open vector control (SVC); V/F (scalar) control. |

||

| Starting torque | G type: 0.5Hz/150% (SVC); 0Hz/180% (FVC). P type: 0.5Hz/100%. |

||

| Speed range | 1: 100 (SVC) | 1: 1000 (FVC) | |

| Speed accuracy | ±0.5% (SVC) | ±0.02% (FVC) | |

| Torque accuracy | ±5% (FVC) | ||

| Overload capacity | G type: 150% rated current 60s; 180% rated current 3s; P type: 120% rated current 60s; 150% rated current 3s. |

||

| Torque boost | Automatic | Manual 0.1%~30.0% | |

| V/F curve | Straight-line V/F curveMulti-point V/F curveN-power V/F curve (2-power, 1.4-power, 1.6-power, 1.8-power, 2-power square) | ||

| V/F separation | Two types: complete separation; half separation. AVR output. | ||

| Ramp mode | Straight-line rampS-curve rampFour groups of acceleration/deceleration time: 0.0-6500.0s | ||

| DC braking | DC braking frequency: 0.00 Hz to maximum frequency Braking time: 0.0-36.0s Braking action current value: 0.0%-100.0% |

||

| JOG control | JOG frequency range: 0.00-50.00 Hz JOG acceleration/deceleration time: 0.0-6500.0s |

||

| Simple PLC | Up to 16 speeds via the simple PLC function or DI terminals | ||

| Onboard PID | Process-controlled closed loop control system | ||

| Auto voltage regulation (VR) | Keep constant output voltage automatically when grid voltage fluctuates. | ||

| Overvoltage/ Overcurrent stall control |

The current and voltage are limited automatically during the running process so as to avoid frequent tripping due to overvoltage/overcurrent. | ||

| Fast current limit function | Protect inverter from overcurrent malfunctions. | ||

| Torque limit and control | It can limit the torque automatically and prevent frequent over current tripping during the running process. Torque control can be implemented in the FVC mode. | ||

| Power DIP ride through |

The regenerative energy from load compensates the voltage reduction so that the inverter can continue to run for a short time. | ||

| Timing control | Time range: 0.0-6500.0 minutes | ||

| Two-motor switchover | Two motors can be switched over via 2 groups of motor parameters. | ||

| Fieldbuses | RS485 | ||

| Operations | Command source | KeyboardControl terminalsSerial communication portYou can perform switchover between these sources in various ways. | |

| Frequency source | 10 frequency sources, such as digital setting, analog voltage setting, analog current setting, pulse setting and serial communication port setting. You can perform switchover between these sources in various ways. | ||

| Auxiliary frequency source | 10 auxiliary frequency sources. It can implement fine tuning of auxiliary frequency and frequency synthesis. | ||

| Input terminal | 5 digital input (DI) terminals; 2 analog input (AI) terminals which support 0-10V voltage input or 0-20mA current input. |

||

| Output terminal | 1 digital output (DO) terminal; 1 relay output terminal; 1 analog output (AO) terminals which support 0-20mA current output or 0-10V voltage. |

||

| Display And Panel | Key lock | It can lock the keys partially or completely and define the function range of some keys so as to prevent misconducts. | |

| Protection functions | Motor short-circuit detection at power-on, input/output phase loss protection, overcurrent protection, overvoltage protection, under voltage protection, overheat protection and overload protection | ||

| Environment | Location | Indoor, free from direct sunlight, dust, corrosive gas, combustible gas, oil smoke, vapor, drip or salt. | |

| Altitude | Less than 1000m. | ||

| Ambient temperature | -10°C to +40°C (de-rated if the ambient temperature is between 40°C and 50°C) | ||

| Humidity | Less than 90%RH, without condensing | ||

| Vibration | Less than 5.8m/s2 (0.6g). | ||

| Storage temperature | -20ºC~+60ºC. | ||

Standard wiring diagram:

Scope of application:

H300 series inverter is widely used in winding machine, fan, pump load, woodworking equipment,lifting equipment,printing bag and other occasions, especially in textile machinery, with good energysaving effect.

Application online images:

DIMENSION:(UNIT:MM)

| Inverter model | Dimensions(mm) | Holes(mm) | Net(Kg) | ||||

| H300-02D2T4G | H | W | D | A | B | ||

| 142 | 85 | 110 | 73 | 130 | φ4.5 | 0.9 | |

Factory outline:

FAQ :

1,Can I get some samples?

Yes, Sample order is available for quality check and market test. Sample product buy 1 set product (1.5KW or 2.2KW)and get free 1 set product(0.4KW or 0,75KW).

2,What’s delivery time?

It usually takes 7-10 working days.

3,What’s your warranty terms?

We offer 2 years warranty time.

4,Can the inverter connect with computer?

Yes, all inverters have built-in RS485 port and support Modbus communication protocol.

5,How does your factory do the quality control?

Quality is priority ,we always attach the importance to quality control from the beginning to the end of the production .Every product will be fully assembled and carefully tested before packing and shipping .

6,Do you have the products in stock?

Depends on your request, we have standard models in stock. Some special products and big order will be newly produced according to your order.

7,Can you sell spare parts?

If you are using CHINAMFG products .we can sell spare parts to you.

8,How can I trust you?

Our company’s values are integrity, responsibility, innovation and cooperation and our company has been audited and approved CE, ISO9001. Assessment report could be sent to you by e-mail. Also we are the made-in-China’s Premium member supplier. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | General Transducer, Single-phase Transducer |

|---|---|

| Output Type: | Single |

| Principle of Work: | AC Inverter |

| Main Circuit Type: | Voltage |

| Voltage of Power Supply: | Low Voltage Variable-Frequency Drive |

| Link of Transformation: | AC-DC-AC Variable-Frequency Drive |

| Samples: |

US$ 52/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can variator motors be used in both fixed and variable speed applications?

Yes, variator motors can be used in both fixed and variable speed applications. Here’s a detailed explanation:

Variator motors, also known as variable speed motors or adjustable speed motors, are designed to provide flexibility in adjusting the motor’s speed according to the specific requirements of the application. This versatility allows them to be used in a wide range of applications, whether the desired speed is fixed or variable.

Here are some key points to consider regarding the use of variator motors in fixed and variable speed applications:

- Fixed Speed Applications: In fixed speed applications, where a constant speed is required throughout the operation, variator motors can still be used effectively. The motor can be set at the desired fixed speed during installation or through the control system. The advantage of using variator motors in fixed speed applications is that they often offer high efficiency and reliable performance, which can contribute to energy savings and reduced maintenance needs.

- Variable Speed Applications: Variator motors are particularly well-suited for variable speed applications, where the speed requirements may change based on different operational conditions or process demands. These motors allow for precise control over the motor’s speed, enabling optimization of the application’s performance. By adjusting the speed according to the specific requirements, variator motors can improve energy efficiency, enhance process control, reduce wear and tear on mechanical components, and enable better synchronization with other system elements.

- Speed Adjustment Range: Variator motors offer a wide range of adjustable speeds, allowing them to accommodate both fixed and variable speed applications. The speed adjustment range can vary depending on the specific model and type of variator motor. Some motors may have a limited range, while others can provide a broad range of speeds, spanning from low RPMs to high RPMs. When selecting a variator motor for a specific application, it’s essential to consider the required speed range and ensure that the motor can operate within those speed limits.

- Control Options: Variator motors often come with various control options that allow for easy adjustment of the motor’s speed. These control options can include manual control through potentiometers or dials, digital control through interface panels or keypads, or even programmable control through communication protocols such as Modbus or Ethernet. These control options facilitate the use of variator motors in both fixed and variable speed applications, as they provide flexibility in setting and changing the desired speed.

- Application Versatility: Variator motors are versatile and find applications in various industries and sectors. They can be used in applications such as conveyors, pumps, fans, compressors, mixers, machine tools, HVAC systems, robotics, and more. This versatility demonstrates how variator motors can be utilized effectively in both fixed and variable speed applications across different industries.

Overall, the use of variator motors offers flexibility and adaptability to meet the speed requirements of different applications, whether fixed or variable. By selecting the appropriate motor model, determining the desired speed range, and utilizing the available control options, variator motors can provide efficient and reliable performance in a wide range of applications.

Are there common troubleshooting issues associated with variator motor operation?

Yes, variator motors can experience common troubleshooting issues during their operation. Here’s a detailed explanation:

1. Overheating: Overheating is a common issue in variator motors and can be caused by factors such as excessive load, inadequate cooling, or motor inefficiencies. Overheating can lead to motor damage and reduced lifespan. Troubleshooting steps may involve checking for proper ventilation, ensuring adequate cooling mechanisms, and verifying that the motor is correctly sized for the application.

2. Noise and Vibration: Excessive noise and vibration can indicate problems with the motor’s bearings, misalignment, unbalanced loads, or mechanical issues. Troubleshooting may involve inspecting and lubricating bearings, aligning motor components, and addressing any mechanical faults.

3. Electrical Issues: Variator motors can experience electrical issues such as phase imbalances, voltage fluctuations, or short circuits. These issues can result in abnormal motor operation or failure. Troubleshooting may involve checking electrical connections, verifying voltage levels, and inspecting motor windings for damage.

4. Poor Performance: Poor motor performance can be caused by factors such as incorrect motor programming, inadequate power supply, or control system malfunctions. Troubleshooting steps may include recalibrating motor parameters, checking power supply stability, and verifying proper functioning of the control system.

5. Start-Up and Stopping Problems: Variator motors may encounter difficulties during start-up or stopping processes. These issues can be related to control system settings, mechanical constraints, or insufficient torque. Troubleshooting may involve adjusting acceleration and deceleration profiles, verifying mechanical components for obstructions, and ensuring sufficient torque for the application.

6. Communication and Networking: Variator motors equipped with communication and networking capabilities may experience troubleshooting issues related to connectivity, data exchange, or software compatibility. Troubleshooting steps may involve checking network configurations, updating firmware or software, and ensuring compatibility between devices and protocols.

7. Environmental Factors: Variator motor operation can be influenced by environmental factors such as temperature, humidity, or contaminants. Extreme temperatures, high humidity, or the presence of dust or debris can impact motor performance. Troubleshooting may involve implementing environmental controls, cleaning motor components, or providing additional protection against harsh conditions.

When troubleshooting variator motor issues, it’s recommended to consult the motor’s documentation, manufacturer’s guidelines, and seek assistance from qualified technicians or engineers. They can provide specific troubleshooting procedures and recommendations based on the motor model and application requirements.

Regular maintenance, periodic inspections, and adherence to operating guidelines can help prevent or mitigate common troubleshooting issues associated with variator motor operation.

What are the advantages of using variator motors in industrial settings?

Variator motors offer several advantages when used in industrial settings. Here are some key benefits:

- Flexible Speed Control: One of the primary advantages of variator motors is their ability to provide flexible speed control. Unlike traditional motors that operate at a fixed speed, variator motors allow for adjustable speed settings. This flexibility enables industrial processes to be optimized for different operational requirements, such as varying loads, different stages of production, or specific process demands.

- Energy Efficiency: Variator motors can help improve energy efficiency in industrial settings. By adjusting the motor speed to match the required output, these motors can avoid the energy losses associated with running at fixed speeds. Operating the motor at lower speeds when the full speed is not necessary can lead to significant energy savings. This energy efficiency not only reduces operational costs but also contributes to sustainability and environmental conservation efforts.

- Precise Process Control: The ability to finely tune the speed of variator motors enables precise process control in industrial settings. Processes that require accurate manipulation of speed, such as mixing, blending, and conveyance, can benefit from variator motors. The adjustable speed allows for better control over product quality, consistency, and production rates.

- Adaptability to Changing Loads: Variator motors are well-suited for applications that experience varying loads. The adjustable speed control allows the motor to respond to changes in load conditions, compensating for fluctuations and ensuring optimal performance. This adaptability is particularly advantageous in industries where load variations are common, such as material handling, conveyor systems, and production lines with varying throughput requirements.

- Reduced Mechanical Stress: In some industrial processes, sudden starts or stops and rapid speed changes can subject mechanical components to excessive stress, leading to premature wear and tear. Variator motors can mitigate this issue by providing smooth and controlled acceleration and deceleration. The ability to gradually ramp up or down the motor speed reduces mechanical stress on the system, prolonging the lifespan of equipment and minimizing maintenance needs.

- Improved Productivity: Variator motors can contribute to improved productivity in industrial settings. The adjustable speed control allows for process optimization, reducing cycle times and enhancing overall efficiency. By matching the motor speed to the specific requirements of each stage of production, variator motors can help streamline operations and increase productivity.

These advantages make variator motors a valuable choice for a wide range of industrial applications. Their flexibility, energy efficiency, precise control, adaptability, and productivity enhancements contribute to improved performance and cost-effectiveness in industrial settings.

editor by CX 2024-04-12

China best Ausenist China Factory Variable Variator De Frequency 5kw 10kw 3 Phase Adjustable Speed Drive 50Hz 60Hz Frequency Inverter VFD VSD Variable AC Motor vacuum pump ac

Product Description

Ausenist EV510 series of high-performance vector inverter is a universal high-performance

current vector inverter, mainly used to control and adjust the three-phase AC induction

motor speed and torque, support a variety of PG card, powerful. Can be used for

textile, paper, drawing, machine tools, packaging, food, fans, pumps and a variety of

automated production equipment drive.

Product features:

Power range :220V/380V/480V/690V/1140V

Support vector control, optional PG card, s closed-loop control, fully functional,

support 3 analog inputs (two current inputs), dual analog outputs, dual relay outputs,

larger size than the market, relatively good heat dissipation, more stable quality

Detailed Photos

Product Parameters

| Item | Specification | ||

| Basic Function |

Maximum Frequency | Vector control: 0~500Hz; V/F control: 0~500Hz |

|

| Carrier Frequency | 0.8KHz~12KHz; the carrier frequency could automatically adjusted based on the load features. |

||

| Input Frequency Resolution |

Digital setting: 0.01Hz; Analog setting: maximum frequency × 0.571% |

||

| Control Mode | Open-loop vector control (SVC); Closed-loop vector control (VC); V/F control |

||

| Starting Torque | G type: 0.5Hz/150% (SVC); 0Hz/180% (FVC) P type: 0.5Hz/100% |

||

| Speed Range | 1:100 (SVC) | 1:1000 (FVC) | |

| Steady Speed Precision | ±0.5% (SVC) | ±0.02% (FVC) | |

| Torque Control Precision |

±5% (FVC) | ||

| Overload Capacity | G type: 150% rated current 60s; 180% rated current 3s P type: 120% rated current 60s; 150% rated current 3s |

||

| Torque Boost | Automatic torque boost; Manual torque boost 0.1%~30.0% |

||

| V/F Curve | Linear type; Multi-point type; The Nth power of V/F curve (1.2th power, 1.4th power, 1.6th power, 1.8th power, 2th power) |

||

| V/F Separation | Overall separation; Semi separation |

||

| ACC/DEC Curve | Linear or S curve of ACC/DEC ways. Four types of ACC/DEC Time, ACC/DEC time range is 0.0~6500.0s. |

||

| DC Brake | DC brake frequency: 0.00Hz~max. frequency Brake time: 0.0s~36.0s Brake action current: 0.0%~100.0% |

||

| JOG Control | JOG frequency range: 0.00Hz~50.00Hz JOG ACC/DEC time: 0.0s~6500.0.s |

||

| Simple PLC, multistage speed running |

Via built-in PLC or control terminal can realize max. 16 stages speed running. |

||

| Built-in PID | Can realize process control close-loop system conveniently. |

||

| Auto Voltage Regulation (AVR) |

It can keep constant output voltage automatically when the network voltage changes. |

||

| Overcurrent and Overvoltage Speed Control |

During running, limit current and voltage automatically, protect from tripping off frequently for over voltage and over current. |

||

| Quick Current-limit Function |

Reduce over current error on max extent, protect inverter normal running. |

||

| Torque Limitation and Control |

“Digger” feature, could limit torque automatically, prevent over current tripping off; closed-loop vector can realize torque control. |

||

| Personable Function |

Outstanding Perform | using high-perform current vector control | |

| Instantaneous Stop Not Stop |

during instant power-off, by motor feedback energy,inverter compensates voltage-drop to keep running for short time | ||

| Quick Current-limit Function |

reduce over current error on max extent | ||

| Timing Control | timing control function: setting time range 0.0min~6500.0min |

||

| Multi-motor Switch | 2 sets of motor parameter, can realize 2 motors switching control. | ||

| Multi-threaded Bus Support |

RS485; CAN open; CAN link | ||

| Multi-encoder Support | differential; open collector; rotary transformer | ||

| Command Source | control panel; control terminal; communication can be switched by several modes |

||

| Frequency Source | 10 types: digital setting, analog voltage setting, analog current setting, pulse setting, communication setting, can be switched by several methods. | ||

| Auxiliary Frequency Sources |

10 types of auxiliary frequency source, can realize auxiliary frequency trimming, frequency combining flexibility. | ||

| Running | Input Terminal | Standard: 7 digital input terminals: one of them support max 100KHz high-speed pulse input; 3 analog input terminals: one support 0~10V voltage input only; one support 0~10V voltage or 0~20mA current input; one support -10~10V voltage input. |

|

| Output Terminal | Standard: 1 high-speed pulse output terminal (optional open collector), support 0~100KHz pulse; 1 digit output terminal; 2 relay output terminals; 2 analog output terminals, 1 of them support 0~20mA current output. |

||

| Display and Keypad |

LED Display | can display parameter | |

| Press-key Locking and Function Selection |

Realize press-key partial or full locking, define part press-key function range, to avoid wrong operation. |

||

| Protection Function | Motor short-circuit detection at power-on, input/output phase loss protection, overcurrent protection,overvoltage protection, undervoltage protection,overheat protection and overload protection. | ||

| Optional Parts | Differential Input PG Card; Rotating Transformer PG Card; OC Input PG Card |

||

| Environment | Installation Location | Indoor, free from direct sunlight, dust, corrosive gas, combustible gas, oil smoke, vapour, drip or salt. |

|

| Altitude | lower than 1000m (derated if higher than 1000m) | ||

| Ambient Temperature | -10ºC~+40ºC (derated if the ambient temperature is between 40ºCand 50ºC) |

||

| Humidity | less than 95%RH, without condensing | ||

| Optional | Double Screens Display LED Panel |

LCD displays the operating panel; universal RJ45 interface |

|

| LCD Panel | LCD displays the operating panel; could copy parameter |

||

| Model | Power Capacity (KVA) |

Input Current (A) |

Output Current (A) |

Match Motor (KW) |

| Single-phase: 220V, 50/60Hz | ||||

| EV510-0004G-S2 | 1 | 5.4 | 2.3 | 0.4 |

| EV510-0007G-S2 | 1.5 | 8.2 | 4 | 0.75 |

| EV510-0015G-S2 | 3 | 14 | 7 | 1.5 |

| EV510-0571G-S2 | 4 | 23 | 9.6 | 2.2 |

| Three-phase: 220V, 50/60Hz | ||||

| EV510-0037G-T2 | 8.9 | 14.6 | 13 | 3.7 |

| EV510-0055G-T2 | 17 | 26 | 25 | 5.5 |

| EV510-0075G-T2 | 21 | 35 | 32 | 7.5 |

| EV510-0110G-T2 | 30 | 46.5 | 45 | 11 |

| EV510-0150G-T2 | 40 | 62 | 60 | 15 |

| EV510-0185G-T2 | 57 | 76 | 75 | 18.5 |

| EV510-5710G-T2 | 69 | 92 | 91 | 22 |

| EV510-0300G-T2 | 85 | 113 | 112 | 30 |

| EV510-571G-T2 | 114 | 157 | 150 | 37 |

| EV510-0450G-T2 | 134 | 180 | 176 | 45 |

| EV510- 0571 G-T2 | 160 | 214 | 210 | 55 |

| EV510-571G-T2 | 231 | 307 | 304 | 75 |

| Three-phase: 380V/480V, 50/60Hz | ||||

| EV510-0007G-T4/T5 | 1.5 | 3.4 | 2.1 | 0.75 |

| EV510-0015G-T4/T5 | 3 | 5 | 3.8 | 1.5 |

| EV510-0571G-T4/T5 | 4 | 5.8 | 5.1 | 2.2 |

| EV510-0037G/0055P-T4/T5 | 5.9 | 10.5 | 9 | 3.7 |

| EV510-0055G/0075P-T4/T5 | 8.9 | 14.6 | 13 | 5.5 |

| EV510-0075G/0110P-T4/T5 | 11 | 20.5 | 17 | 7.5 |

| EV510-0110G/0150P-T4/T5 | 17 | 26 | 25 | 11 |

| EV510-0150G/0185P-T4/T5 | 21 | 35 | 32 | 15 |

| EV510-0185G/5710P-T4/T5 | 24 | 38.5 | 37 | 18.5 |

| EV510-5710G/0300P-T4/T5 | 30 | 46.5 | 45 | 22 |

| EV510-0300G/571P-T4/T5 | 40 | 62 | 60 | 30 |

| EV510-571G/0450P-T4/T5 | 57 | 76 | 75 | 37 |

| EV510-0450G/ 0571 P-T4/T5 | 69 | 92 | 91 | 45 |

| EV510- 0571 G/571P-T4/T5 | 85 | 113 | 112 | 55 |

| EV510-571G/0900P-T4/T5 | 114 | 157 | 150 | 75 |

| EV510-0900G/1100P-T4/T5 | 134 | 180 | 176 | 90 |

| EV510-1100G/1320P-T4/T5 | 160 | 214 | 210 | 110 |

| EV510-1320G/1600P-T4/T5 | 192 | 256 | 253 | 132 |

| EV510-1600G/2000P-T4/T5 | 231 | 307 | 304 | 160 |

| EV510-2000G/2200P-T4/T5 | 250 | 385 | 377 | 200 |

| EV510-2200G/2500P-T4/T5 | 280 | 430 | 426 | 220 |

| EV510-2500G/2800P-T4/T5 | 355 | 468 | 465 | 250 |

| EV510-2800G/3150P-T4/T5 | 396 | 525 | 520 | 280 |

| EV510-3150G/3550P-T4/T5 | 445 | 590 | 585 | 315 |

| EV510-3550G-T4/T5 | 500 | 665 | 650 | 350 |

| EV510-4000G-T4/T5 | 565 | 785 | 725 | 400 |

| EV510-5000G-T4/T5 | 700 | 890 | 870 | 500 |

| EV510-5600G-T4/T5 | 783 | 980 | 950 | 560 |

| EV510-6300G-T4/T5 | 882 | 1180 | 1100 | 630 |

| Three-phase: 690V, 50/60Hz | ||||

| EV510- 0571 G-T6 | 84 | 70 | 65 | 55 |

| EV510-571G-T6 | 107 | 90 | 86 | 75 |

| EV510-0900G-T6 | 125 | 105 | 100 | 90 |

| EV510-1100G-T6 | 155 | 130 | 120 | 110 |

| EV510-1320G-T6 | 192 | 170 | 150 | 132 |

| EV510-1600G-T6 | 231 | 200 | 175 | 160 |

| EV510-2000G-T6 | 250 | 235 | 215 | 200 |

| EV510-2200G-T6 | 280 | 247 | 245 | 220 |

| EV510-2500G-T6 | 355 | 265 | 260 | 250 |

| EV510-2800G-T6 | 396 | 305 | 299 | 280 |

| EV510-3150G-T6 | 445 | 350 | 330 | 315 |

| EV510-3550G-T6 | 500 | 382 | 374 | 355 |

| EV510-4000G-T6 | 565 | 435 | 410 | 400 |

Company Profile

Ausenist engaged in the research, development, production, sales and service of the inverters. Our company is positioned to serve the industrial equipment manufacturers, we not only provide customers with practical products and convenient services continuously, but also individually tailored product and comprehensive solution for particular industry.

| 1/ Trading FAQ | ||

| 1 | Delivery date: | 1 week ~2 week,depend on quantity |

| 2 | OEM | Accept OEM with your authorization |

| 3 | Packaging Details: | Export standard package or special package according to customer requirement |

| 4 | Payment Term: | T/T, L/C at sight Western Union or others for negotiation |

| 5 | Samples : | Samples will be prepared to sending in about 3-5 working days. |

| 6 | Sample Delivery date: | (And DHL 4-7days; UPS 4-7days; Fedex / TNT 4-8days; EMS 9 days to reach destination) |

| 7 | Quotation Valid: | Price Valid 2 months. |

| 8 | Warranty : | 18 Months |

| 9 | Market | Europ, Middle East, South America, Asia, Afria etc |

| 2/ Strictly QC management | ||

| 1 | IQC( Income Quality Control) | |

| 2 | IPQC( In process Quality Control) | |

| 3 | FQC( Finish Quality Control) | |

| 4 | OQC( Outgoing Quality Control) | |

| 5 | AGING TEST, LOAD TEST AND SO ON | |

| 3/ Our advantage | ||

| 1 | More than 20 years– manufacture of frequency inverter | |

| 2 | More than 15 years– experience in OEM items | |

| 3 | More than 100 countries– exported | |

| 4 | More than 50 R&D team– OEM, ODM accepted | |

| 5 | More than 100,000 pcs production capacity per month | |

| 6 | Got NO.6 Inverter brand award in China | |

| 7 | Got ISO9001,CE ,CCC certificates and Own Patent | |

| 8 | Experienced and Professional Automation control solution Provider | |

| 9 | Offer the optional spare parts for frequency inverter & whole solution for automation system. | |

| 4/ Products Brief | ||

| 1 | JT550 Series & D32 Series & EV510 Series | High Performance Vector control VFD |

| 2 | JT300 Series | Economic Vector control VFD |

| 3 | JT580 Series | High Protection VFD with built in DC reactor |

| 4 | JT550 Series | Through-the-wall Vector control VFD |

| 5 | JS500 Series | Construction Lifting Integrated Machine VFD |

| 6 | JS500 Series | Material Lifting Integrated Machine VFD |

| 7 | Synchronous servo drive | |

| 8 | Synchronous moter drive | |

| 9 | Programmable Logic Controller (PLC) | |

| 10 | 3 Phase Permanent Magnet Synchronous High-Efficiency Motor | |

| 11 | KY550 HDMI | |

| 12 | TDS servo system | |

After Sales Service

| Power range | 0.4KW-3.7KW | 0.75KW-37KW | Above 37KW | |

| Provision of quality service | Return period | one month | one month | nonsupport |

| Exchange period | 3 month | 3 month | nonsupport | |

| Warranty period | 18 month | 18 month | 18 month | |

FAQ

1. What voltage range can you support?

Single-phase 220v input, single-phase 220v output;

Single-phase 220v input, three-phase 220v output;

Three-phase 220v input, three-phase 220v output;

Single-phase 220v input, three-phase 380v output;

2. How to choose the power of the frequency inverter?

According to your motor power, you can click “Chat Now” on the right and our sales staff will provide you with solutions online.

3. Do you support urgent orders?

Of course. We have an ERP management system. Once there is an inventory warning, we will prepare materials in advance to meet the urgent needs of customers.

5. How to ensure product quality?

Our production strictly follow ISO9001 quality control system. After 4 times quality inspect and high temperature testing we will print “QA” pass.

6. Do you accept OEM business?

We accept OEM and ODM with your authorization.

7.Can I have a sample order?

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

8.What about the lead time?

Sample needed 3-5 days, mass production time needed 1-2 weeks.

9:How about your payment and shipment?

Payment: We accept T/T, Western Union, Paypal etc. terms of payment.

Shipment: For sample order, we use DHL, TNT, FEDEX, EMS etc.express; for batch order, by sea or by air.

10.Do you have any MOQ limit?

1pc for sample checking available.

11.Do you offer guarantee for the products?

Yes, we offer 18 months warranty.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | High-performance Transducer, Three Phase Transducer, General Transducer, Single-phase Transducer, High Frequency Converter Transducer, Metallurgy, Plastomer,Textile, Food-Stuff,Petroleu |

|---|---|

| Output Type: | Triple |

| Principle of Work: | V/F ,Vector, Pid , PLC |

| Switch Mode: | High Carrier Frequency PWM Control |

| Main Circuit Type: | Voltage |

| Voltage of Power Supply: | Low / Midium / High Voltage VFD |

| Samples: |

US$ 90/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What factors should be considered when selecting a variator motor for a specific application?

When selecting a variator motor for a specific application, several factors should be considered to ensure optimal performance and compatibility. Here are some key factors to take into account:

- Load Characteristics: Consider the specific characteristics of the load the motor will be driving. This includes factors such as the torque requirements, speed range, and variations in load demand. Understanding the load characteristics helps in selecting a variator motor with the appropriate power and speed capabilities to meet the application’s requirements.

- Speed Range: Determine the required speed range for the application. Variator motors offer the advantage of adjustable speed control, but different models may have different speed ranges. Ensure that the selected variator motor can operate within the desired speed range to meet the application’s needs.

- Power Rating: Consider the power rating required by the application. This involves assessing the motor’s ability to deliver the necessary torque and power output to drive the load effectively. It’s important to select a variator motor that can handle the power requirements of the application without operating at its maximum capacity continuously.

- Environmental Conditions: Evaluate the environmental conditions in which the variator motor will operate. Factors such as temperature, humidity, dust, vibrations, and corrosive substances can impact motor performance and longevity. Choose a variator motor that is designed to withstand the specific environmental conditions of the application, such as motors with appropriate protection ratings or specialized coatings.

- Efficiency and Energy Savings: Consider the desired energy efficiency of the system. Variator motors can offer energy savings through adjustable speed control, but efficiency levels can vary between models. Look for motors with high efficiency ratings, such as those meeting energy efficiency standards like IE3 or IE4, to optimize energy consumption and reduce operating costs.

- Control and Integration Requirements: Assess the control and integration needs of the application. Determine whether the variator motor requires specific control interfaces or communication protocols to integrate with the automation system effectively. Consider compatibility with existing control systems, such as programmable logic controllers (PLCs) or industrial communication networks, to ensure seamless integration and ease of operation.

- Reliability and Maintenance: Evaluate the reliability and maintenance requirements of the variator motor. Consider factors such as the expected lifespan, durability of components, availability of spare parts, and ease of maintenance. Choosing a motor from a reputable manufacturer with a track record of reliable products and good customer support can help ensure long-term performance and minimize downtime.

- Cost Considerations: Finally, consider the cost of the variator motor, including the initial purchase cost as well as long-term operating costs. While it’s important to find a motor that meets the application’s requirements, it’s also essential to consider the overall cost-effectiveness and return on investment. This includes factors such as energy savings, maintenance costs, and potential productivity gains.

By carefully considering these factors, you can select a variator motor that is well-suited to the specific application, delivering optimal performance, energy efficiency, and reliability.

How do variator motors contribute to energy efficiency in manufacturing processes?

Variator motors play a significant role in improving energy efficiency in manufacturing processes. Here’s a detailed explanation:

Variator motors, also known as variable speed motors or adjustable speed drives, offer the ability to adjust the motor’s speed and torque according to the requirements of the manufacturing process. This flexibility provides several ways in which variator motors contribute to energy efficiency:

- Optimized Process Control: By varying the motor’s speed, variator motors allow manufacturers to precisely match the motor’s output to the process requirements. This optimization eliminates the need for constant full-speed operation, which can result in unnecessary energy consumption. Instead, the motor can run at reduced speeds during periods of lower demand, resulting in energy savings.

- Reduced Mechanical Losses: Traditional motors operating at fixed speeds often use mechanical devices, such as throttling valves or dampers, to control the process flow or pressure. These devices introduce additional mechanical losses that consume energy. With variator motors, the motor speed can be adjusted directly, eliminating the need for such mechanical control devices and reducing energy losses associated with them.

- Efficient Motor Operation: Variator motors are designed to operate efficiently over a broad range of speeds. Unlike fixed-speed motors that may experience reduced efficiency at lower speeds, variator motors can maintain high efficiency even at reduced speeds. This efficiency is achieved through advanced motor designs, improved motor control algorithms, and the use of technologies like permanent magnet motors or synchronous reluctance motors.

- Power Factor Correction: Variator motors can incorporate power factor correction (PFC) techniques to improve the power factor of the motor. Power factor is a measure of how effectively the motor utilizes the supplied electrical power. By improving the power factor, variator motors reduce the reactive power drawn from the power grid, resulting in lower electricity bills and reduced strain on the electrical distribution system.

- Energy Recovery: Some variator motors can feature regenerative capabilities, allowing them to recover and feed excess energy back into the power grid or reuse it within the manufacturing process. For example, in applications where the motor decelerates or operates as a generator, the energy generated can be fed back into the grid or used to power other equipment, further enhancing energy efficiency.

- Process Optimization: Variator motors offer the advantage of precise control over motor speed and torque. This control can be utilized to optimize manufacturing processes, such as matching the motor speed to the optimal speed for material handling, mixing, or other process requirements. By fine-tuning the motor operation, variator motors enable improved process efficiency, reduced material waste, and energy savings.

By leveraging the flexibility and control offered by variator motors, manufacturers can achieve substantial energy savings in their production processes. The specific energy-saving potential will depend on the application, process requirements, and the extent to which the motor’s speed and torque can be optimized. It’s important to consult with motor manufacturers, engineers, and energy experts to assess the suitability and potential energy savings of variator motors in specific manufacturing applications.

How does the efficiency of variator motors compare to other types of motors?

The efficiency of variator motors can vary depending on the specific design, application, and operating conditions. However, in general, variator motors can offer comparable or even higher efficiency compared to other types of motors. Here are some key points to consider:

- Variable Speed Operation: Variator motors excel in variable speed operations where the motor speed can be adjusted to match the load and process requirements. By running the motor at a speed that precisely meets the demand, variator motors can significantly reduce energy losses associated with running at fixed speeds. This level of control contributes to high overall system efficiency.

- Energy Savings through Speed Control: The ability to adjust the motor speed in variator motors allows for energy savings. By operating the motor at lower speeds when full speed is not required, variator motors can achieve energy efficiency gains. This is particularly relevant in applications with varying loads or processes that do not constantly require maximum speed.

- Improved Power Factor: Variator motors with adjustable speed control, such as those incorporating variable frequency drives (VFDs), can improve the power factor of the motor system. Power factor is a measure of how effectively electrical power is being used. By optimizing the motor speed and voltage, VFDs can improve the power factor, resulting in reduced reactive power consumption and improved energy efficiency.

- Motor Design and Technology: The efficiency of variator motors can also be influenced by the motor design and the use of advanced technologies. Manufacturers are continually improving motor designs, incorporating high-quality materials, precision manufacturing techniques, and efficient cooling systems to enhance motor efficiency. Additionally, advancements in motor technologies, such as the use of permanent magnet materials and improved motor control algorithms, contribute to higher overall efficiency.

- Comparison with Other Motor Types: When compared to traditional fixed-speed motors, variator motors generally offer higher efficiency due to their ability to adjust speed according to the load. In applications where variable speed control is required, variator motors can outperform fixed-speed motors in terms of energy savings, precise control, and overall system efficiency.

It’s important to note that the efficiency of variator motors can also depend on factors such as motor size, load characteristics, maintenance practices, and system design. Therefore, it’s advisable to consider specific motor specifications, consult with manufacturers, and conduct energy efficiency assessments to determine the most suitable motor type for a given application.

editor by CX 2024-03-27

China OEM Ausenist China Factory Variable Variator De Frequency 5kw 10kw 3 Phase Adjustable Speed Drive 50Hz 60Hz Frequency Inverter VFD VSD Variable AC Motor supplier

Product Description

Ausenist EV510 series of high-performance vector inverter is a universal high-performance

current vector inverter, mainly used to control and adjust the three-phase AC induction

motor speed and torque, support a variety of PG card, powerful. Can be used for

textile, paper, drawing, machine tools, packaging, food, fans, pumps and a variety of

automated production equipment drive.

Product features:

Power range :220V/380V/480V/690V/1140V

Support vector control, optional PG card, s closed-loop control, fully functional,

support 3 analog inputs (two current inputs), dual analog outputs, dual relay outputs,

larger size than the market, relatively good heat dissipation, more stable quality

Detailed Photos

Product Parameters

| Item | Specification | ||

| Basic Function |

Maximum Frequency | Vector control: 0~500Hz; V/F control: 0~500Hz |

|

| Carrier Frequency | 0.8KHz~12KHz; the carrier frequency could automatically adjusted based on the load features. |

||

| Input Frequency Resolution |

Digital setting: 0.01Hz; Analog setting: maximum frequency × 0.571% |

||

| Control Mode | Open-loop vector control (SVC); Closed-loop vector control (VC); V/F control |

||

| Starting Torque | G type: 0.5Hz/150% (SVC); 0Hz/180% (FVC) P type: 0.5Hz/100% |

||

| Speed Range | 1:100 (SVC) | 1:1000 (FVC) | |

| Steady Speed Precision | ±0.5% (SVC) | ±0.02% (FVC) | |

| Torque Control Precision |

±5% (FVC) | ||

| Overload Capacity | G type: 150% rated current 60s; 180% rated current 3s P type: 120% rated current 60s; 150% rated current 3s |

||

| Torque Boost | Automatic torque boost; Manual torque boost 0.1%~30.0% |

||

| V/F Curve | Linear type; Multi-point type; The Nth power of V/F curve (1.2th power, 1.4th power, 1.6th power, 1.8th power, 2th power) |

||

| V/F Separation | Overall separation; Semi separation |

||

| ACC/DEC Curve | Linear or S curve of ACC/DEC ways. Four types of ACC/DEC Time, ACC/DEC time range is 0.0~6500.0s. |

||

| DC Brake | DC brake frequency: 0.00Hz~max. frequency Brake time: 0.0s~36.0s Brake action current: 0.0%~100.0% |

||

| JOG Control | JOG frequency range: 0.00Hz~50.00Hz JOG ACC/DEC time: 0.0s~6500.0.s |

||

| Simple PLC, multistage speed running |

Via built-in PLC or control terminal can realize max. 16 stages speed running. |

||

| Built-in PID | Can realize process control close-loop system conveniently. |

||

| Auto Voltage Regulation (AVR) |

It can keep constant output voltage automatically when the network voltage changes. |

||

| Overcurrent and Overvoltage Speed Control |

During running, limit current and voltage automatically, protect from tripping off frequently for over voltage and over current. |

||

| Quick Current-limit Function |

Reduce over current error on max extent, protect inverter normal running. |

||

| Torque Limitation and Control |

“Digger” feature, could limit torque automatically, prevent over current tripping off; closed-loop vector can realize torque control. |

||

| Personable Function |

Outstanding Perform | using high-perform current vector control | |

| Instantaneous Stop Not Stop |

during instant power-off, by motor feedback energy,inverter compensates voltage-drop to keep running for short time | ||

| Quick Current-limit Function |

reduce over current error on max extent | ||

| Timing Control | timing control function: setting time range 0.0min~6500.0min |

||

| Multi-motor Switch | 2 sets of motor parameter, can realize 2 motors switching control. | ||

| Multi-threaded Bus Support |

RS485; CAN open; CAN link | ||

| Multi-encoder Support | differential; open collector; rotary transformer | ||

| Command Source | control panel; control terminal; communication can be switched by several modes |

||

| Frequency Source | 10 types: digital setting, analog voltage setting, analog current setting, pulse setting, communication setting, can be switched by several methods. | ||

| Auxiliary Frequency Sources |

10 types of auxiliary frequency source, can realize auxiliary frequency trimming, frequency combining flexibility. | ||

| Running | Input Terminal | Standard: 7 digital input terminals: one of them support max 100KHz high-speed pulse input; 3 analog input terminals: one support 0~10V voltage input only; one support 0~10V voltage or 0~20mA current input; one support -10~10V voltage input. |

|

| Output Terminal | Standard: 1 high-speed pulse output terminal (optional open collector), support 0~100KHz pulse; 1 digit output terminal; 2 relay output terminals; 2 analog output terminals, 1 of them support 0~20mA current output. |

||

| Display and Keypad |

LED Display | can display parameter | |

| Press-key Locking and Function Selection |

Realize press-key partial or full locking, define part press-key function range, to avoid wrong operation. |

||

| Protection Function | Motor short-circuit detection at power-on, input/output phase loss protection, overcurrent protection,overvoltage protection, undervoltage protection,overheat protection and overload protection. | ||

| Optional Parts | Differential Input PG Card; Rotating Transformer PG Card; OC Input PG Card |

||

| Environment | Installation Location | Indoor, free from direct sunlight, dust, corrosive gas, combustible gas, oil smoke, vapour, drip or salt. |

|

| Altitude | lower than 1000m (derated if higher than 1000m) | ||

| Ambient Temperature | -10ºC~+40ºC (derated if the ambient temperature is between 40ºCand 50ºC) |

||

| Humidity | less than 95%RH, without condensing | ||

| Optional | Double Screens Display LED Panel |

LCD displays the operating panel; universal RJ45 interface |

|

| LCD Panel | LCD displays the operating panel; could copy parameter |

||

| Model | Power Capacity (KVA) |

Input Current (A) |

Output Current (A) |

Match Motor (KW) |

| Single-phase: 220V, 50/60Hz | ||||

| EV510-0004G-S2 | 1 | 5.4 | 2.3 | 0.4 |

| EV510-0007G-S2 | 1.5 | 8.2 | 4 | 0.75 |

| EV510-0015G-S2 | 3 | 14 | 7 | 1.5 |

| EV510-0571G-S2 | 4 | 23 | 9.6 | 2.2 |

| Three-phase: 220V, 50/60Hz | ||||

| EV510-0037G-T2 | 8.9 | 14.6 | 13 | 3.7 |

| EV510-0055G-T2 | 17 | 26 | 25 | 5.5 |

| EV510-0075G-T2 | 21 | 35 | 32 | 7.5 |

| EV510-0110G-T2 | 30 | 46.5 | 45 | 11 |

| EV510-0150G-T2 | 40 | 62 | 60 | 15 |

| EV510-0185G-T2 | 57 | 76 | 75 | 18.5 |

| EV510-5710G-T2 | 69 | 92 | 91 | 22 |

| EV510-0300G-T2 | 85 | 113 | 112 | 30 |

| EV510-571G-T2 | 114 | 157 | 150 | 37 |

| EV510-0450G-T2 | 134 | 180 | 176 | 45 |

| EV510- 0571 G-T2 | 160 | 214 | 210 | 55 |

| EV510-571G-T2 | 231 | 307 | 304 | 75 |

| Three-phase: 380V/480V, 50/60Hz | ||||

| EV510-0007G-T4/T5 | 1.5 | 3.4 | 2.1 | 0.75 |

| EV510-0015G-T4/T5 | 3 | 5 | 3.8 | 1.5 |

| EV510-0571G-T4/T5 | 4 | 5.8 | 5.1 | 2.2 |

| EV510-0037G/0055P-T4/T5 | 5.9 | 10.5 | 9 | 3.7 |

| EV510-0055G/0075P-T4/T5 | 8.9 | 14.6 | 13 | 5.5 |

| EV510-0075G/0110P-T4/T5 | 11 | 20.5 | 17 | 7.5 |

| EV510-0110G/0150P-T4/T5 | 17 | 26 | 25 | 11 |

| EV510-0150G/0185P-T4/T5 | 21 | 35 | 32 | 15 |

| EV510-0185G/5710P-T4/T5 | 24 | 38.5 | 37 | 18.5 |

| EV510-5710G/0300P-T4/T5 | 30 | 46.5 | 45 | 22 |

| EV510-0300G/571P-T4/T5 | 40 | 62 | 60 | 30 |

| EV510-571G/0450P-T4/T5 | 57 | 76 | 75 | 37 |

| EV510-0450G/ 0571 P-T4/T5 | 69 | 92 | 91 | 45 |

| EV510- 0571 G/571P-T4/T5 | 85 | 113 | 112 | 55 |

| EV510-571G/0900P-T4/T5 | 114 | 157 | 150 | 75 |

| EV510-0900G/1100P-T4/T5 | 134 | 180 | 176 | 90 |

| EV510-1100G/1320P-T4/T5 | 160 | 214 | 210 | 110 |

| EV510-1320G/1600P-T4/T5 | 192 | 256 | 253 | 132 |

| EV510-1600G/2000P-T4/T5 | 231 | 307 | 304 | 160 |

| EV510-2000G/2200P-T4/T5 | 250 | 385 | 377 | 200 |

| EV510-2200G/2500P-T4/T5 | 280 | 430 | 426 | 220 |

| EV510-2500G/2800P-T4/T5 | 355 | 468 | 465 | 250 |

| EV510-2800G/3150P-T4/T5 | 396 | 525 | 520 | 280 |

| EV510-3150G/3550P-T4/T5 | 445 | 590 | 585 | 315 |

| EV510-3550G-T4/T5 | 500 | 665 | 650 | 350 |

| EV510-4000G-T4/T5 | 565 | 785 | 725 | 400 |

| EV510-5000G-T4/T5 | 700 | 890 | 870 | 500 |

| EV510-5600G-T4/T5 | 783 | 980 | 950 | 560 |

| EV510-6300G-T4/T5 | 882 | 1180 | 1100 | 630 |

| Three-phase: 690V, 50/60Hz | ||||

| EV510- 0571 G-T6 | 84 | 70 | 65 | 55 |

| EV510-571G-T6 | 107 | 90 | 86 | 75 |

| EV510-0900G-T6 | 125 | 105 | 100 | 90 |

| EV510-1100G-T6 | 155 | 130 | 120 | 110 |

| EV510-1320G-T6 | 192 | 170 | 150 | 132 |

| EV510-1600G-T6 | 231 | 200 | 175 | 160 |

| EV510-2000G-T6 | 250 | 235 | 215 | 200 |

| EV510-2200G-T6 | 280 | 247 | 245 | 220 |

| EV510-2500G-T6 | 355 | 265 | 260 | 250 |

| EV510-2800G-T6 | 396 | 305 | 299 | 280 |

| EV510-3150G-T6 | 445 | 350 | 330 | 315 |

| EV510-3550G-T6 | 500 | 382 | 374 | 355 |

| EV510-4000G-T6 | 565 | 435 | 410 | 400 |

Company Profile

Ausenist engaged in the research, development, production, sales and service of the inverters. Our company is positioned to serve the industrial equipment manufacturers, we not only provide customers with practical products and convenient services continuously, but also individually tailored product and comprehensive solution for particular industry.

| 1/ Trading FAQ | ||

| 1 | Delivery date: | 1 week ~2 week,depend on quantity |

| 2 | OEM | Accept OEM with your authorization |

| 3 | Packaging Details: | Export standard package or special package according to customer requirement |

| 4 | Payment Term: | T/T, L/C at sight Western Union or others for negotiation |

| 5 | Samples : | Samples will be prepared to sending in about 3-5 working days. |

| 6 | Sample Delivery date: | (And DHL 4-7days; UPS 4-7days; Fedex / TNT 4-8days; EMS 9 days to reach destination) |

| 7 | Quotation Valid: | Price Valid 2 months. |

| 8 | Warranty : | 18 Months |

| 9 | Market | Europ, Middle East, South America, Asia, Afria etc |

| 2/ Strictly QC management | ||

| 1 | IQC( Income Quality Control) | |

| 2 | IPQC( In process Quality Control) | |

| 3 | FQC( Finish Quality Control) | |

| 4 | OQC( Outgoing Quality Control) | |

| 5 | AGING TEST, LOAD TEST AND SO ON | |

| 3/ Our advantage | ||

| 1 | More than 20 years– manufacture of frequency inverter | |

| 2 | More than 15 years– experience in OEM items | |

| 3 | More than 100 countries– exported | |

| 4 | More than 50 R&D team– OEM, ODM accepted | |

| 5 | More than 100,000 pcs production capacity per month | |

| 6 | Got NO.6 Inverter brand award in China | |

| 7 | Got ISO9001,CE ,CCC certificates and Own Patent | |

| 8 | Experienced and Professional Automation control solution Provider | |

| 9 | Offer the optional spare parts for frequency inverter & whole solution for automation system. | |

| 4/ Products Brief | ||

| 1 | JT550 Series & D32 Series & EV510 Series | High Performance Vector control VFD |

| 2 | JT300 Series | Economic Vector control VFD |

| 3 | JT580 Series | High Protection VFD with built in DC reactor |

| 4 | JT550 Series | Through-the-wall Vector control VFD |

| 5 | JS500 Series | Construction Lifting Integrated Machine VFD |

| 6 | JS500 Series | Material Lifting Integrated Machine VFD |

| 7 | Synchronous servo drive | |

| 8 | Synchronous moter drive | |

| 9 | Programmable Logic Controller (PLC) | |

| 10 | 3 Phase Permanent Magnet Synchronous High-Efficiency Motor | |

| 11 | KY550 HDMI | |

| 12 | TDS servo system | |

After Sales Service

| Power range | 0.4KW-3.7KW | 0.75KW-37KW | Above 37KW | |

| Provision of quality service | Return period | one month | one month | nonsupport |

| Exchange period | 3 month | 3 month | nonsupport | |

| Warranty period | 18 month | 18 month | 18 month | |

FAQ

1. What voltage range can you support?

Single-phase 220v input, single-phase 220v output;

Single-phase 220v input, three-phase 220v output;

Three-phase 220v input, three-phase 220v output;

Single-phase 220v input, three-phase 380v output;

2. How to choose the power of the frequency inverter?

According to your motor power, you can click “Chat Now” on the right and our sales staff will provide you with solutions online.

3. Do you support urgent orders?

Of course. We have an ERP management system. Once there is an inventory warning, we will prepare materials in advance to meet the urgent needs of customers.

5. How to ensure product quality?

Our production strictly follow ISO9001 quality control system. After 4 times quality inspect and high temperature testing we will print “QA” pass.

6. Do you accept OEM business?

We accept OEM and ODM with your authorization.

7.Can I have a sample order?

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

8.What about the lead time?

Sample needed 3-5 days, mass production time needed 1-2 weeks.

9:How about your payment and shipment?

Payment: We accept T/T, Western Union, Paypal etc. terms of payment.

Shipment: For sample order, we use DHL, TNT, FEDEX, EMS etc.express; for batch order, by sea or by air.

10.Do you have any MOQ limit?

1pc for sample checking available.

11.Do you offer guarantee for the products?

Yes, we offer 18 months warranty.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | High-performance Transducer, Three Phase Transducer, General Transducer, Single-phase Transducer, High Frequency Converter Transducer, Metallurgy, Plastomer,Textile, Food-Stuff,Petroleu |

|---|---|

| Output Type: | Triple |

| Principle of Work: | V/F ,Vector, Pid , PLC |

| Switch Mode: | High Carrier Frequency PWM Control |

| Main Circuit Type: | Voltage |

| Voltage of Power Supply: | Low / Midium / High Voltage VFD |

| Samples: |

US$ 90/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Are variator motors suitable for applications requiring precise speed control?

Yes, variator motors are generally suitable for applications requiring precise speed control. Here’s a detailed explanation:

Variator motors, also known as variable speed motors or adjustable speed motors, are designed to provide adjustable speed control over a wide range. They allow the user to vary the motor’s speed according to the specific requirements of the application. This flexibility makes them well-suited for applications that demand precise speed control.

Here are some reasons why variator motors are suitable for applications requiring precise speed control:

- Speed Adjustment Range: Variator motors offer a wide range of adjustable speeds, allowing for precise control over the motor’s rotational speed. Depending on the specific model and type of variator motor, the speed adjustment range can vary from a few RPM (Revolutions Per Minute) to thousands of RPM. This versatility enables the motor to operate at different speeds, accommodating varying process or load requirements.

- Smooth Speed Transitions: Variator motors can provide smooth and gradual speed transitions. They offer precise speed control without sudden jolts or jerks during acceleration or deceleration. This feature is especially important in applications where precise speed control is critical for maintaining product quality, preventing damage to sensitive equipment, or ensuring smooth operation of processes.

- Speed Accuracy and Stability: Variator motors can achieve high speed accuracy and stability. They can maintain the desired speed setting within tight tolerances, minimizing deviations and fluctuations. This level of control is essential in applications that require precise synchronization, coordination with other system components, or adherence to specific speed profiles.

- Control Options: Variator motors often come with various control options, allowing for precise speed adjustments. These options can include manual control through potentiometers or dials, digital control through interface panels or keypads, or even programmable control through communication protocols such as Modbus or Ethernet. The availability of different control options enhances the motor’s suitability for applications requiring precise speed control.

- Response Time: Variator motors can typically achieve fast response times when adjusting the speed. They can quickly respond to speed commands or changes in the control signal, allowing for precise and immediate adjustments. This responsiveness is beneficial in applications where rapid speed changes or dynamic response is required to meet changing operational conditions.

- Closed-Loop Control Capability: Some variator motors are equipped with closed-loop control capabilities. Closed-loop control involves using feedback sensors, such as encoders or tachometers, to continuously monitor the motor’s actual speed and compare it to the desired speed. The control system adjusts the motor’s speed based on this feedback, ensuring precise speed control and compensating for any variations or disturbances.

- Application Versatility: Variator motors are versatile and can be used in a wide range of applications requiring precise speed control. They find applications in industries such as manufacturing, automation, robotics, HVAC (heating, ventilation, and air conditioning), conveyors, pumps, fans, and many others.

However, it’s important to note that the suitability of variator motors for precise speed control may vary depending on factors such as the specific motor model, control system, and the desired level of precision. It’s recommended to consult the motor manufacturer or an expert in motor control to determine the best solution for a particular application.

What are the key components and technologies used in modern variator motors?

Modern variator motors incorporate several key components and technologies to enable their variable speed and adjustable torque capabilities. Here’s a detailed explanation:

1. Motor Stator and Rotor: The motor stator and rotor are fundamental components of variator motors. The stator consists of a stationary set of windings that generate a rotating magnetic field when energized. The rotor, typically mounted on the motor shaft, contains conductive bars or coils that interact with the magnetic field and produce mechanical rotation.

2. Power Electronics: Variator motors rely on power electronics components, such as inverters or variable frequency drives (VFDs), to control the motor’s speed and torque. These devices convert the incoming AC power supply into the appropriate voltage and frequency required by the motor. Power electronics also enable smooth and precise adjustment of motor operating parameters, facilitating variable speed operation.

3. Sensors and Feedback Devices: Variator motors often incorporate sensors and feedback devices to monitor motor performance and provide input for control algorithms. Common sensors used include speed sensors, position sensors, temperature sensors, and current sensors. These sensors provide real-time information about the motor’s operating conditions, allowing the control system to adjust motor parameters accordingly.

4. Control Algorithms and Software: Modern variator motors employ sophisticated control algorithms and software to regulate motor speed, torque, and other operating parameters. These algorithms process the sensor data and generate control signals to adjust the power electronics and optimize motor performance. Advanced control techniques, such as field-oriented control (FOC) or model predictive control (MPC), may be used to achieve precise and efficient motor operation.

5. Variable Speed Drive Mechanisms: Variator motors employ various mechanisms to achieve variable speed operation. These mechanisms can include adjustable pulley systems, belt drives, gearboxes, or electronic control of motor winding configurations. The specific mechanism depends on the motor’s design and application requirements.

6. Efficiency-Enhancing Technologies: Modern variator motors incorporate technologies aimed at improving energy efficiency and reducing losses. These technologies may include the use of high-efficiency motor designs, such as permanent magnet motors or synchronous reluctance motors. Additionally, advanced insulation materials, optimized motor cooling systems, and reduced friction bearings can contribute to enhanced motor efficiency.

7. Communication and Networking: Some variator motors feature communication and networking capabilities to enable integration with industrial automation systems or the Internet of Things (IoT). These capabilities facilitate remote monitoring, control, and data exchange, allowing for enhanced motor performance analysis, predictive maintenance, and system integration.

8. Safety and Protection Features: Modern variator motors incorporate safety and protection features to safeguard the motor and the surrounding equipment. These features may include overcurrent protection, overvoltage protection, short-circuit protection, thermal protection, and fault detection mechanisms. These measures ensure safe and reliable operation and help prevent damage to the motor in case of abnormal operating conditions.

The specific components and technologies used in variator motors can vary depending on the motor’s type, design, and application requirements. Motor manufacturers continuously innovate and incorporate advancements in materials, electronics, and control systems to improve motor performance, efficiency, and reliability.

Are there specific types of variator motors designed for certain tasks or environments?

Yes, there are specific types of variator motors that are designed to suit certain tasks or operate effectively in specific environments. Here are some examples: