Product Description

Product Description:

H300 series simple inverter has a wide range of speed regulation,high accuracy, fast dynamic response, high operating efficiency, easy to operate and a series of advantages, mainly used in textile machinery, machine equipment, fan, pump load and other occasions.

Power class: 220V 1PH ,0.4-2.2KW

380V 3PH ,0.75-5.5KW

Name plate :

Product Features:

Multiple protection features:

H300 Series Model:

H300 Series Techinical Standard:

| Item | Specifications | ||

| Basic Functions | Control system | Current Vector General Purpose Inverter. | |

| Compatible motor | Induction motors. | ||

| Maximum frequency | Vector control: 0~500Hz; V/F control: 0~500Hz. |

||

| Carrier frequency | 0.8kHz~12kHz; Depending on load, can automatically adjust. | ||

| Input resolution | Digital: 0.01Hz; | Analog: maximum frequency×0.1%. | |

| Control modes | Open vector control (SVC); V/F (scalar) control. |

||

| Starting torque | G type: 0.5Hz/150% (SVC); 0Hz/180% (FVC). P type: 0.5Hz/100%. |

||

| Speed range | 1: 100 (SVC) | 1: 1000 (FVC) | |

| Speed accuracy | ±0.5% (SVC) | ±0.02% (FVC) | |

| Torque accuracy | ±5% (FVC) | ||

| Overload capacity | G type: 150% rated current 60s; 180% rated current 3s; P type: 120% rated current 60s; 150% rated current 3s. |

||

| Torque boost | Automatic | Manual 0.1%~30.0% | |

| V/F curve | Straight-line V/F curveMulti-point V/F curveN-power V/F curve (2-power, 1.4-power, 1.6-power, 1.8-power, 2-power square) | ||

| V/F separation | Two types: complete separation; half separation. AVR output. | ||

| Ramp mode | Straight-line rampS-curve rampFour groups of acceleration/deceleration time: 0.0-6500.0s | ||

| DC braking | DC braking frequency: 0.00 Hz to maximum frequency Braking time: 0.0-36.0s Braking action current value: 0.0%-100.0% |

||

| JOG control | JOG frequency range: 0.00-50.00 Hz JOG acceleration/deceleration time: 0.0-6500.0s |

||

| Simple PLC | Up to 16 speeds via the simple PLC function or DI terminals | ||

| Onboard PID | Process-controlled closed loop control system | ||

| Auto voltage regulation (VR) | Keep constant output voltage automatically when grid voltage fluctuates. | ||

| Overvoltage/ Overcurrent stall control |

The current and voltage are limited automatically during the running process so as to avoid frequent tripping due to overvoltage/overcurrent. | ||

| Fast current limit function | Protect inverter from overcurrent malfunctions. | ||

| Torque limit and control | It can limit the torque automatically and prevent frequent over current tripping during the running process. Torque control can be implemented in the FVC mode. | ||

| Power DIP ride through |

The regenerative energy from load compensates the voltage reduction so that the inverter can continue to run for a short time. | ||

| Timing control | Time range: 0.0-6500.0 minutes | ||

| Two-motor switchover | Two motors can be switched over via 2 groups of motor parameters. | ||

| Fieldbuses | RS485 | ||

| Operations | Command source | KeyboardControl terminalsSerial communication portYou can perform switchover between these sources in various ways. | |

| Frequency source | 10 frequency sources, such as digital setting, analog voltage setting, analog current setting, pulse setting and serial communication port setting. You can perform switchover between these sources in various ways. | ||

| Auxiliary frequency source | 10 auxiliary frequency sources. It can implement fine tuning of auxiliary frequency and frequency synthesis. | ||

| Input terminal | 5 digital input (DI) terminals; 2 analog input (AI) terminals which support 0-10V voltage input or 0-20mA current input. |

||

| Output terminal | 1 digital output (DO) terminal; 1 relay output terminal; 1 analog output (AO) terminals which support 0-20mA current output or 0-10V voltage. |

||

| Display And Panel | Key lock | It can lock the keys partially or completely and define the function range of some keys so as to prevent misconducts. | |

| Protection functions | Motor short-circuit detection at power-on, input/output phase loss protection, overcurrent protection, overvoltage protection, under voltage protection, overheat protection and overload protection | ||

| Environment | Location | Indoor, free from direct sunlight, dust, corrosive gas, combustible gas, oil smoke, vapor, drip or salt. | |

| Altitude | Less than 1000m. | ||

| Ambient temperature | -10°C to +40°C (de-rated if the ambient temperature is between 40°C and 50°C) | ||

| Humidity | Less than 90%RH, without condensing | ||

| Vibration | Less than 5.8m/s2 (0.6g). | ||

| Storage temperature | -20ºC~+60ºC. | ||

Standard wiring diagram:

Scope of application:

H300 series inverter is widely used in winding machine, fan, pump load, woodworking equipment,lifting equipment,printing bag and other occasions, especially in textile machinery, with good energysaving effect.

Application online images:

DIMENSION:(UNIT:MM)

| Inverter model | Dimensions(mm) | Holes(mm) | Net(Kg) | ||||

| H300-02D2T4G | H | W | D | A | B | ||

| 142 | 85 | 110 | 73 | 130 | φ4.5 | 0.9 | |

Factory outline:

FAQ :

1,Can I get some samples?

Yes, Sample order is available for quality check and market test. Sample product buy 1 set product (1.5KW or 2.2KW)and get free 1 set product(0.4KW or 0,75KW).

2,What’s delivery time?

It usually takes 7-10 working days.

3,What’s your warranty terms?

We offer 2 years warranty time.

4,Can the inverter connect with computer?

Yes, all inverters have built-in RS485 port and support Modbus communication protocol.

5,How does your factory do the quality control?

Quality is priority ,we always attach the importance to quality control from the beginning to the end of the production .Every product will be fully assembled and carefully tested before packing and shipping .

6,Do you have the products in stock?

Depends on your request, we have standard models in stock. Some special products and big order will be newly produced according to your order.

7,Can you sell spare parts?

If you are using CHINAMFG products .we can sell spare parts to you.

8,How can I trust you?

Our company’s values are integrity, responsibility, innovation and cooperation and our company has been audited and approved CE, ISO9001. Assessment report could be sent to you by e-mail. Also we are the made-in-China’s Premium member supplier. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | General Transducer, Single-phase Transducer |

|---|---|

| Output Type: | Single |

| Principle of Work: | AC Inverter |

| Main Circuit Type: | Voltage |

| Voltage of Power Supply: | Low Voltage Variable-Frequency Drive |

| Link of Transformation: | AC-DC-AC Variable-Frequency Drive |

| Samples: |

US$ 52/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

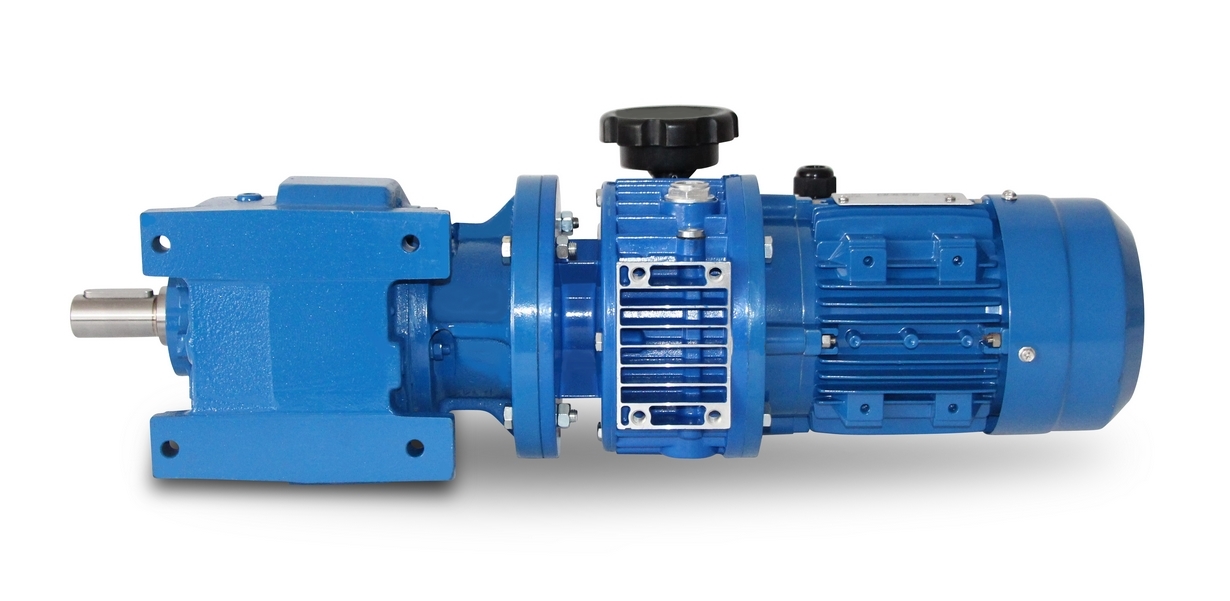

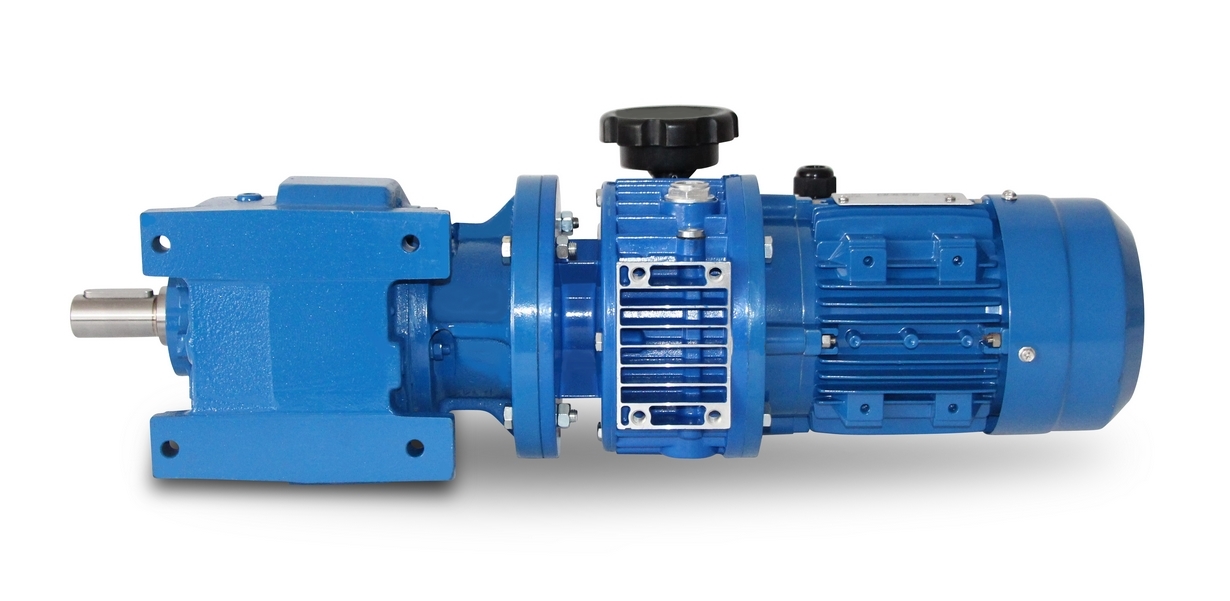

Can variator motors be used in both fixed and variable speed applications?

Yes, variator motors can be used in both fixed and variable speed applications. Here’s a detailed explanation:

Variator motors, also known as variable speed motors or adjustable speed motors, are designed to provide flexibility in adjusting the motor’s speed according to the specific requirements of the application. This versatility allows them to be used in a wide range of applications, whether the desired speed is fixed or variable.

Here are some key points to consider regarding the use of variator motors in fixed and variable speed applications:

- Fixed Speed Applications: In fixed speed applications, where a constant speed is required throughout the operation, variator motors can still be used effectively. The motor can be set at the desired fixed speed during installation or through the control system. The advantage of using variator motors in fixed speed applications is that they often offer high efficiency and reliable performance, which can contribute to energy savings and reduced maintenance needs.

- Variable Speed Applications: Variator motors are particularly well-suited for variable speed applications, where the speed requirements may change based on different operational conditions or process demands. These motors allow for precise control over the motor’s speed, enabling optimization of the application’s performance. By adjusting the speed according to the specific requirements, variator motors can improve energy efficiency, enhance process control, reduce wear and tear on mechanical components, and enable better synchronization with other system elements.

- Speed Adjustment Range: Variator motors offer a wide range of adjustable speeds, allowing them to accommodate both fixed and variable speed applications. The speed adjustment range can vary depending on the specific model and type of variator motor. Some motors may have a limited range, while others can provide a broad range of speeds, spanning from low RPMs to high RPMs. When selecting a variator motor for a specific application, it’s essential to consider the required speed range and ensure that the motor can operate within those speed limits.

- Control Options: Variator motors often come with various control options that allow for easy adjustment of the motor’s speed. These control options can include manual control through potentiometers or dials, digital control through interface panels or keypads, or even programmable control through communication protocols such as Modbus or Ethernet. These control options facilitate the use of variator motors in both fixed and variable speed applications, as they provide flexibility in setting and changing the desired speed.

- Application Versatility: Variator motors are versatile and find applications in various industries and sectors. They can be used in applications such as conveyors, pumps, fans, compressors, mixers, machine tools, HVAC systems, robotics, and more. This versatility demonstrates how variator motors can be utilized effectively in both fixed and variable speed applications across different industries.

Overall, the use of variator motors offers flexibility and adaptability to meet the speed requirements of different applications, whether fixed or variable. By selecting the appropriate motor model, determining the desired speed range, and utilizing the available control options, variator motors can provide efficient and reliable performance in a wide range of applications.

Are there common troubleshooting issues associated with variator motor operation?

Yes, variator motors can experience common troubleshooting issues during their operation. Here’s a detailed explanation:

1. Overheating: Overheating is a common issue in variator motors and can be caused by factors such as excessive load, inadequate cooling, or motor inefficiencies. Overheating can lead to motor damage and reduced lifespan. Troubleshooting steps may involve checking for proper ventilation, ensuring adequate cooling mechanisms, and verifying that the motor is correctly sized for the application.

2. Noise and Vibration: Excessive noise and vibration can indicate problems with the motor’s bearings, misalignment, unbalanced loads, or mechanical issues. Troubleshooting may involve inspecting and lubricating bearings, aligning motor components, and addressing any mechanical faults.

3. Electrical Issues: Variator motors can experience electrical issues such as phase imbalances, voltage fluctuations, or short circuits. These issues can result in abnormal motor operation or failure. Troubleshooting may involve checking electrical connections, verifying voltage levels, and inspecting motor windings for damage.

4. Poor Performance: Poor motor performance can be caused by factors such as incorrect motor programming, inadequate power supply, or control system malfunctions. Troubleshooting steps may include recalibrating motor parameters, checking power supply stability, and verifying proper functioning of the control system.

5. Start-Up and Stopping Problems: Variator motors may encounter difficulties during start-up or stopping processes. These issues can be related to control system settings, mechanical constraints, or insufficient torque. Troubleshooting may involve adjusting acceleration and deceleration profiles, verifying mechanical components for obstructions, and ensuring sufficient torque for the application.

6. Communication and Networking: Variator motors equipped with communication and networking capabilities may experience troubleshooting issues related to connectivity, data exchange, or software compatibility. Troubleshooting steps may involve checking network configurations, updating firmware or software, and ensuring compatibility between devices and protocols.

7. Environmental Factors: Variator motor operation can be influenced by environmental factors such as temperature, humidity, or contaminants. Extreme temperatures, high humidity, or the presence of dust or debris can impact motor performance. Troubleshooting may involve implementing environmental controls, cleaning motor components, or providing additional protection against harsh conditions.

When troubleshooting variator motor issues, it’s recommended to consult the motor’s documentation, manufacturer’s guidelines, and seek assistance from qualified technicians or engineers. They can provide specific troubleshooting procedures and recommendations based on the motor model and application requirements.

Regular maintenance, periodic inspections, and adherence to operating guidelines can help prevent or mitigate common troubleshooting issues associated with variator motor operation.

What are the advantages of using variator motors in industrial settings?

Variator motors offer several advantages when used in industrial settings. Here are some key benefits:

- Flexible Speed Control: One of the primary advantages of variator motors is their ability to provide flexible speed control. Unlike traditional motors that operate at a fixed speed, variator motors allow for adjustable speed settings. This flexibility enables industrial processes to be optimized for different operational requirements, such as varying loads, different stages of production, or specific process demands.

- Energy Efficiency: Variator motors can help improve energy efficiency in industrial settings. By adjusting the motor speed to match the required output, these motors can avoid the energy losses associated with running at fixed speeds. Operating the motor at lower speeds when the full speed is not necessary can lead to significant energy savings. This energy efficiency not only reduces operational costs but also contributes to sustainability and environmental conservation efforts.

- Precise Process Control: The ability to finely tune the speed of variator motors enables precise process control in industrial settings. Processes that require accurate manipulation of speed, such as mixing, blending, and conveyance, can benefit from variator motors. The adjustable speed allows for better control over product quality, consistency, and production rates.

- Adaptability to Changing Loads: Variator motors are well-suited for applications that experience varying loads. The adjustable speed control allows the motor to respond to changes in load conditions, compensating for fluctuations and ensuring optimal performance. This adaptability is particularly advantageous in industries where load variations are common, such as material handling, conveyor systems, and production lines with varying throughput requirements.

- Reduced Mechanical Stress: In some industrial processes, sudden starts or stops and rapid speed changes can subject mechanical components to excessive stress, leading to premature wear and tear. Variator motors can mitigate this issue by providing smooth and controlled acceleration and deceleration. The ability to gradually ramp up or down the motor speed reduces mechanical stress on the system, prolonging the lifespan of equipment and minimizing maintenance needs.

- Improved Productivity: Variator motors can contribute to improved productivity in industrial settings. The adjustable speed control allows for process optimization, reducing cycle times and enhancing overall efficiency. By matching the motor speed to the specific requirements of each stage of production, variator motors can help streamline operations and increase productivity.

These advantages make variator motors a valuable choice for a wide range of industrial applications. Their flexibility, energy efficiency, precise control, adaptability, and productivity enhancements contribute to improved performance and cost-effectiveness in industrial settings.

editor by CX 2024-04-12