Product Description

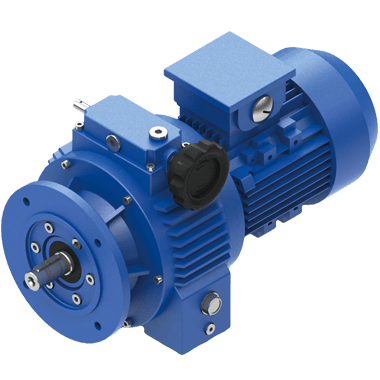

JWB-X SERIES SPEED VARIATOR

Characteristics

JWB-X With great reliability developed over 30 years of service, the JWB-X series is a valid alternative to electronic drives and is easy to use and maintain.

The JWB-X type in cast iron includes a wide range of models with flange, feet, with input shaft or in motorized version, are available in size number 04 and 05 ,input power is 1.1kw, 1.5kw,2.2kw,3kw,4kw.

The low-cost, light weight JWB-X B versions in aluminium,are available in size number 01, 02 and 03,04, input power is 0.18kw,0.25kw,0.37kw,0.55kw , 0.75kw,1.1kw and 1.5kw.

All type Certifications Available: ISO,CE,CQC,TUV,CCC certificate.

JWB-X type

- Sizes: 04,05

- Motor Power from 1.1 kW to 4 kW (Incldue 1.1kW,1.5kW,2.2kW,3kW,4kW)

- Cases in RAL 5571 blue cast iron

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors:

190-950r/min; 100-500r/min;80-400r/min;60-300r/min;40-200r/min;

30-150r/min;28-140r/min; 20-100r/min; 15-75r/min;4.7-23.5r/min;2-10r/min;

Output Torque value max 535Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control handwheel positionable on either side

- Slipping speed to max load at 5%

- Painted with blue epoxy-polyester powder

JWB-X B type

- Sizes: 01,02,03 and 04

- Motor Power up to 1.5 kW or less

(Incldue 0.18kW,0.25kW,0.37kW,0.55kW,0.75kW,1.1kW,1.5kW)

- Cases in die-cast aluminium alloy

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors:

190r/min-950r/min; 100r/min-500r/min;80r/min-400r/min;60r/min-300r/min;

40r/min-200r/min;28r/min-140r/min;25-125r/min; 18-90r/min; 15r/min-75r/min;

13-65r/min; 9-45r/min; 8-40r/min; 6.5-32.5r/min;4.7r/min-23.5r/min;2r/min-10r/min.

- Output Torque value max 795 Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control hand wheel positionable on either side

- Slipping speed to max load at 5%

- Painted with blue epoxy-polyester powder

| SPEED VARIATOR | Output Speed Range: | ||||

| SWB SERIES | 2rpm-950rpm | ||||

| Applicable Motor Power: | |||||

| 0.18kW-7.5kW | |||||

| Input Options 1: | |||||

| Type | Old Type | Output Torque | Output Shaft Dia. | With Inline AC Motor | |

| SWB01 | JWB01 | 2.6-1.6N.m | φ11 | Input Options 2: | |

| SWB02 | JWB02 | 258-1.8N.m | φ14, φ24, φ28, φ32 | With IEC Motor | |

| SWB03 | JWB03 | 426-4N.m | φ24, φ28, φ28, φ38 | Input Options 3: | |

| SWB04 | JWB04 | 795-8N.m | φ28, φ38, φ38, φ42 | With Input Shaft | |

| SWB05 | JWB05 | 535-16N.m | φ38, φ48, φ55 | Input Options 4: | |

| SWB06 | JWB06 | 1002-40N.m | φ42, φ55, φ70 | With Input Flange |

Starshine Drive

Certificate

Our Team

Quality Control

Packing

Delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Ceramic, Glass, Logistic |

|---|---|

| Certification: | CE, ISO, CQC,SGS,TUV |

| Structure: | Horizontal |

| Control System: | Manual Adjustment |

| Glass Washing Machine Type: | Transmission Parts |

| Grinding Head Number: | Transmission Parts |

| Samples: |

US$ 300/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can variator motors be used in both fixed and variable speed applications?

Yes, variator motors can be used in both fixed and variable speed applications. Here’s a detailed explanation:

Variator motors, also known as variable speed motors or adjustable speed motors, are designed to provide flexibility in adjusting the motor’s speed according to the specific requirements of the application. This versatility allows them to be used in a wide range of applications, whether the desired speed is fixed or variable.

Here are some key points to consider regarding the use of variator motors in fixed and variable speed applications:

- Fixed Speed Applications: In fixed speed applications, where a constant speed is required throughout the operation, variator motors can still be used effectively. The motor can be set at the desired fixed speed during installation or through the control system. The advantage of using variator motors in fixed speed applications is that they often offer high efficiency and reliable performance, which can contribute to energy savings and reduced maintenance needs.

- Variable Speed Applications: Variator motors are particularly well-suited for variable speed applications, where the speed requirements may change based on different operational conditions or process demands. These motors allow for precise control over the motor’s speed, enabling optimization of the application’s performance. By adjusting the speed according to the specific requirements, variator motors can improve energy efficiency, enhance process control, reduce wear and tear on mechanical components, and enable better synchronization with other system elements.

- Speed Adjustment Range: Variator motors offer a wide range of adjustable speeds, allowing them to accommodate both fixed and variable speed applications. The speed adjustment range can vary depending on the specific model and type of variator motor. Some motors may have a limited range, while others can provide a broad range of speeds, spanning from low RPMs to high RPMs. When selecting a variator motor for a specific application, it’s essential to consider the required speed range and ensure that the motor can operate within those speed limits.

- Control Options: Variator motors often come with various control options that allow for easy adjustment of the motor’s speed. These control options can include manual control through potentiometers or dials, digital control through interface panels or keypads, or even programmable control through communication protocols such as Modbus or Ethernet. These control options facilitate the use of variator motors in both fixed and variable speed applications, as they provide flexibility in setting and changing the desired speed.

- Application Versatility: Variator motors are versatile and find applications in various industries and sectors. They can be used in applications such as conveyors, pumps, fans, compressors, mixers, machine tools, HVAC systems, robotics, and more. This versatility demonstrates how variator motors can be utilized effectively in both fixed and variable speed applications across different industries.

Overall, the use of variator motors offers flexibility and adaptability to meet the speed requirements of different applications, whether fixed or variable. By selecting the appropriate motor model, determining the desired speed range, and utilizing the available control options, variator motors can provide efficient and reliable performance in a wide range of applications.

Where can individuals find reputable suppliers or manufacturers of variator motors?

Individuals seeking reputable suppliers or manufacturers of variator motors have several options available. Here’s a detailed explanation:

1. Online Directories and Marketplaces: Online directories and marketplaces dedicated to industrial products and components can be a valuable resource. Platforms like Thomasnet, Alibaba, and GlobalSpec provide comprehensive listings of variator motor suppliers and manufacturers. These platforms often include detailed company profiles, product catalogs, and customer reviews, enabling individuals to assess the reputation and credibility of potential suppliers.

2. Trade Shows and Exhibitions: Attending trade shows and exhibitions related to the industrial or manufacturing sector can provide direct access to variator motor manufacturers and suppliers. These events offer opportunities to explore a wide range of products, interact with industry professionals, and establish contacts with reputable companies. Popular trade shows in the field include Hannover Messe, SPS IPC Drives, and Automation Fair.

3. Industry Associations and Organizations: Industry associations and organizations focused on electrical motors, automation, or specific industrial sectors often maintain directories or member listings that can help individuals find reputable variator motor suppliers. Examples include the International Electrotechnical Commission (IEC), National Electrical Manufacturers Association (NEMA), or sector-specific associations like the Robotics Industries Association (RIA) or the Packaging Machinery Manufacturers Institute (PMMI).

4. Consulting with Industry Professionals: Seeking advice and recommendations from industry professionals, such as engineers, consultants, or system integrators, can provide valuable insights on reputable variator motor suppliers. These professionals have experience with various suppliers and can offer guidance based on specific application requirements and industry knowledge.

5. Referrals and Word of Mouth: Networking within professional circles or reaching out to colleagues and peers in the industry can yield recommendations for reputable variator motor suppliers. Word of mouth referrals from trusted sources can provide firsthand information about the quality, reliability, and customer service of different suppliers.

6. Online Research and Reviews: Conducting online research and reading reviews about variator motor suppliers can help individuals gauge their reputation and assess customer satisfaction. Online forums, industry-specific websites, and social media platforms can provide insights and feedback from other customers who have worked with variator motor suppliers.

When evaluating variator motor suppliers or manufacturers, it’s important to consider factors such as their experience in the industry, product quality, certifications, technical support, warranty terms, and after-sales service. Requesting product samples, specifications, and references from potential suppliers can also help individuals make informed decisions.

By leveraging these resources and conducting thorough research, individuals can find reputable suppliers or manufacturers of variator motors that meet their specific requirements and ensure the quality and reliability of the products they purchase.

Can you explain the principle behind the variable speed control in variator motors?

The variable speed control in variator motors is achieved through various mechanisms depending on the specific type of variator motor. Here, we’ll explore a few common principles behind variable speed control:

- Adjustable Transmission Systems: Many variator motors utilize adjustable transmission systems to achieve variable speed control. One common example is the use of variable frequency drives (VFDs) in electric motors. VFDs facilitate speed control by adjusting the frequency of the electrical power supplied to the motor. By modifying the frequency, the VFD can change the rotational speed of the motor. Another example is the use of mechanical gearboxes with different gear ratios. By selecting different gears, the input speed can be converted to various output speeds, allowing for speed control.

- Electronic Control Systems: Some variator motors employ electronic control systems to achieve variable speed control. These control systems typically consist of microprocessors, sensors, and feedback mechanisms. The motor speed is adjusted based on input signals or commands received by the control system. The control system then modulates the power supplied to the motor to achieve the desired speed. This approach is often used in applications where precise speed control and automation are required.

- Hydraulic Control Systems: In hydraulic variator motors, speed control is achieved through hydraulic control systems. These systems use hydraulic pumps, valves, and actuators to adjust the motor speed. By controlling the flow rate and pressure of the hydraulic fluid, the speed of the motor can be modulated. Hydraulic variator motors are commonly used in applications where high torque and ruggedness are required, such as heavy machinery and construction equipment.

Regardless of the specific mechanism used, the principle behind variable speed control in variator motors involves adjusting the input power, transmission, or control system to modify the rotational speed of the motor. This flexibility in controlling the speed allows for precise matching of the motor’s output to the requirements of the application, resulting in improved efficiency, reduced energy consumption, and enhanced performance.

editor by CX 2024-05-14

China OEM Flange Mounted Speed Variator Reducer with motor with Hot selling

Product Description

JWB Series Speed Variator

1. Features:

JWB-X type

- Sizes: ≥04

- Power up to 1.5 kW or more

- Cases in RAL 5571 blue cast iron

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors: 2-10r/min;4.7-23.5r/min;15-75r/min;20-100r/min, 28-140r/min, 30-150r/min;40-200r/min;60-300r/min;80-400r/min;100-500r/min;190-950r/min.

- Output Torque value max 1002Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control handwheel positionable on either side

- Slipping speed to max load at 5%

- Regulation sensibility: 0,5 rpm

- Painted with blue epoxy-polyester powder

JWB-X B type

- Sizes:01,02,03 and 04

- Power up to 1.5 kW or less

- Cases in die-cast aluminium alloy

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors: 2r/min-20r/min;4.7r/min-23.5r/min;6.5-32.5r/min, 8-40r/min, 9-45r/min, 13-65r/min, 15r/min-75r/min;18-90r/min, 25-125r/min, 28r/min-140r/min;40r/min-200r/min;60r/min-300r/min;80r/min-400r/min;100r/min-500r/min;190r/min-950r/min.

- Output Torque value max 795 Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control hand wheel positionable on either side

- Slipping speed to max load at 5%

- Regulation sensibility: 0,5 rpm

- Painted with blue epoxy-polyester powder

2. Technical parameters

| Type | Output Torque | Output Shaft Dia. | Output Speed Range | 2rpm-950rpm | |

| SWB01 | 2.6-1.6N.m | φ11 | Applicable Motor Power | 0.18kW-7.5kW | |

| SWB02 | 258-1.8N.m | φ14,φ24,φ28,φ32 | |||

| SWB03 | 426-4N.m | φ24,φ28,φ38 | Input Options | With Inline AC Motor | |

| SWB04 | 795-8N.m | φ28,φ38,φ42 | With IEC Motor | ||

| SWB05 | 535-16N.m | φ38,φ48,φ55 | With Input Shaft | ||

| SWB06 | 1002-40N.m | φ42,φ55,φ70 | With Input Flange | ||

About Us

ZheJiang CHINAMFG Drive Co.,Ltd,the predecessor was a state-owned military mould enterprise, was established in 1965. CHINAMFG specializes in the complete power transmission solution for high-end equipment manufacturing industries based on the aim of “Platform Product, Application Design and Professional Service”.

Starshine have a strong technical force with over 350 employees at present, including over 30 engineering technicians, 30 quality inspectors, covering an area of 80000 square CHINAMFG and kinds of advanced processing machines and testing equipments. We have a good foundation for the industry application development and service of high-end speed reducers & variators owning to the provincial engineering technology research center,the lab of gear speed reducers, and the base of modern R&D.

Our Team

Quality Control

Quality:Insist on Improvement,Strive for Excellence With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of excellence

Quality Philosophy:Quality creates value

3. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection; responsible for tracking bad, to monitor the supplier to take corrective

measures to prevent recurrence.

4. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend;

found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state.

5. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer’s position on the finished product quality verification, in order to ensure the quality of

customer expectations and needs.

6. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the

product is a product inspection to determine the qualified products.

7. Certification.

Packing

Delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery, Ceramics/Porcelain |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Layout: | Expansion |

| Gear Shape: | Planet Wheel |

| Step: | Stepless |

| Customization: |

Available

|

|

|---|

Are variator motors suitable for applications requiring precise speed control?

Yes, variator motors are generally suitable for applications requiring precise speed control. Here’s a detailed explanation:

Variator motors, also known as variable speed motors or adjustable speed motors, are designed to provide adjustable speed control over a wide range. They allow the user to vary the motor’s speed according to the specific requirements of the application. This flexibility makes them well-suited for applications that demand precise speed control.

Here are some reasons why variator motors are suitable for applications requiring precise speed control:

- Speed Adjustment Range: Variator motors offer a wide range of adjustable speeds, allowing for precise control over the motor’s rotational speed. Depending on the specific model and type of variator motor, the speed adjustment range can vary from a few RPM (Revolutions Per Minute) to thousands of RPM. This versatility enables the motor to operate at different speeds, accommodating varying process or load requirements.

- Smooth Speed Transitions: Variator motors can provide smooth and gradual speed transitions. They offer precise speed control without sudden jolts or jerks during acceleration or deceleration. This feature is especially important in applications where precise speed control is critical for maintaining product quality, preventing damage to sensitive equipment, or ensuring smooth operation of processes.

- Speed Accuracy and Stability: Variator motors can achieve high speed accuracy and stability. They can maintain the desired speed setting within tight tolerances, minimizing deviations and fluctuations. This level of control is essential in applications that require precise synchronization, coordination with other system components, or adherence to specific speed profiles.

- Control Options: Variator motors often come with various control options, allowing for precise speed adjustments. These options can include manual control through potentiometers or dials, digital control through interface panels or keypads, or even programmable control through communication protocols such as Modbus or Ethernet. The availability of different control options enhances the motor’s suitability for applications requiring precise speed control.

- Response Time: Variator motors can typically achieve fast response times when adjusting the speed. They can quickly respond to speed commands or changes in the control signal, allowing for precise and immediate adjustments. This responsiveness is beneficial in applications where rapid speed changes or dynamic response is required to meet changing operational conditions.

- Closed-Loop Control Capability: Some variator motors are equipped with closed-loop control capabilities. Closed-loop control involves using feedback sensors, such as encoders or tachometers, to continuously monitor the motor’s actual speed and compare it to the desired speed. The control system adjusts the motor’s speed based on this feedback, ensuring precise speed control and compensating for any variations or disturbances.

- Application Versatility: Variator motors are versatile and can be used in a wide range of applications requiring precise speed control. They find applications in industries such as manufacturing, automation, robotics, HVAC (heating, ventilation, and air conditioning), conveyors, pumps, fans, and many others.

However, it’s important to note that the suitability of variator motors for precise speed control may vary depending on factors such as the specific motor model, control system, and the desired level of precision. It’s recommended to consult the motor manufacturer or an expert in motor control to determine the best solution for a particular application.

Where can individuals find reputable suppliers or manufacturers of variator motors?

Individuals seeking reputable suppliers or manufacturers of variator motors have several options available. Here’s a detailed explanation:

1. Online Directories and Marketplaces: Online directories and marketplaces dedicated to industrial products and components can be a valuable resource. Platforms like Thomasnet, Alibaba, and GlobalSpec provide comprehensive listings of variator motor suppliers and manufacturers. These platforms often include detailed company profiles, product catalogs, and customer reviews, enabling individuals to assess the reputation and credibility of potential suppliers.

2. Trade Shows and Exhibitions: Attending trade shows and exhibitions related to the industrial or manufacturing sector can provide direct access to variator motor manufacturers and suppliers. These events offer opportunities to explore a wide range of products, interact with industry professionals, and establish contacts with reputable companies. Popular trade shows in the field include Hannover Messe, SPS IPC Drives, and Automation Fair.

3. Industry Associations and Organizations: Industry associations and organizations focused on electrical motors, automation, or specific industrial sectors often maintain directories or member listings that can help individuals find reputable variator motor suppliers. Examples include the International Electrotechnical Commission (IEC), National Electrical Manufacturers Association (NEMA), or sector-specific associations like the Robotics Industries Association (RIA) or the Packaging Machinery Manufacturers Institute (PMMI).

4. Consulting with Industry Professionals: Seeking advice and recommendations from industry professionals, such as engineers, consultants, or system integrators, can provide valuable insights on reputable variator motor suppliers. These professionals have experience with various suppliers and can offer guidance based on specific application requirements and industry knowledge.

5. Referrals and Word of Mouth: Networking within professional circles or reaching out to colleagues and peers in the industry can yield recommendations for reputable variator motor suppliers. Word of mouth referrals from trusted sources can provide firsthand information about the quality, reliability, and customer service of different suppliers.

6. Online Research and Reviews: Conducting online research and reading reviews about variator motor suppliers can help individuals gauge their reputation and assess customer satisfaction. Online forums, industry-specific websites, and social media platforms can provide insights and feedback from other customers who have worked with variator motor suppliers.

When evaluating variator motor suppliers or manufacturers, it’s important to consider factors such as their experience in the industry, product quality, certifications, technical support, warranty terms, and after-sales service. Requesting product samples, specifications, and references from potential suppliers can also help individuals make informed decisions.

By leveraging these resources and conducting thorough research, individuals can find reputable suppliers or manufacturers of variator motors that meet their specific requirements and ensure the quality and reliability of the products they purchase.

Can you explain the principle behind the variable speed control in variator motors?

The variable speed control in variator motors is achieved through various mechanisms depending on the specific type of variator motor. Here, we’ll explore a few common principles behind variable speed control:

- Adjustable Transmission Systems: Many variator motors utilize adjustable transmission systems to achieve variable speed control. One common example is the use of variable frequency drives (VFDs) in electric motors. VFDs facilitate speed control by adjusting the frequency of the electrical power supplied to the motor. By modifying the frequency, the VFD can change the rotational speed of the motor. Another example is the use of mechanical gearboxes with different gear ratios. By selecting different gears, the input speed can be converted to various output speeds, allowing for speed control.

- Electronic Control Systems: Some variator motors employ electronic control systems to achieve variable speed control. These control systems typically consist of microprocessors, sensors, and feedback mechanisms. The motor speed is adjusted based on input signals or commands received by the control system. The control system then modulates the power supplied to the motor to achieve the desired speed. This approach is often used in applications where precise speed control and automation are required.

- Hydraulic Control Systems: In hydraulic variator motors, speed control is achieved through hydraulic control systems. These systems use hydraulic pumps, valves, and actuators to adjust the motor speed. By controlling the flow rate and pressure of the hydraulic fluid, the speed of the motor can be modulated. Hydraulic variator motors are commonly used in applications where high torque and ruggedness are required, such as heavy machinery and construction equipment.

Regardless of the specific mechanism used, the principle behind variable speed control in variator motors involves adjusting the input power, transmission, or control system to modify the rotational speed of the motor. This flexibility in controlling the speed allows for precise matching of the motor’s output to the requirements of the application, resulting in improved efficiency, reduced energy consumption, and enhanced performance.

editor by CX 2024-05-06

china Cheap Flange Mounted Helical Gear Motor Reducer manufacturers

Item Description

XGK Series HELICAL-HYPOID Equipment Models

The hypoid gear has lower friction, performance is as high as 92%,in contrast with the CZPT box ,the effectiveness enhanced about 10%-forty%.The hypoid gear created of large top quality alloy,dealt with by floor hardening,and produced by substantial-precision grinding machine, the output torque,equipment power and life are significantly better than CZPT box.

Traits

one.More substantial reduction ratio with challenging surface area hypoid bevel equipment and CZPT cal equipment generate

2.Large output torque, large transmission effectiveness, vitality-conserving

three.Fantastic casting of aluminum alloy, gentle bodyweight, rust-evidence

four.Steady transmission, reduced sound, suitable for the terrible functioning condition

5.Great look and sturdiness modest volume

six.A variety of mounting positions, vast application, easy utilizing

7.Mounting dimension is interchangeable with RV series CZPT reducer

eight.Modularity on style:

Enter: linked with IEC regular flange motor and servo motor with several technical specs

Output:hollow shaft and strong shaft

nine.Multi-phases equipment travel. It is divided into two-stage generate(one hypoid bevel gear and 1 CZPT cal gear) and a few-stage drive(1 hypoid bevel gear and two CZPT cal gears). In comparison with RV series CZPT and worm shaft composition, it has much more refined ratio and wider software

ABOUT STARSHINE DRIVE

ZheJiang CZPT glow CZPT Co.,Ltd(Starshine) have a powerful specialized drive with above 350 workers at existing, including in excess of thirty CZPT professionals, thirty quality inspectors, masking an location of 80000 square meters and types of CZPT d processing devices and testing equipments. We have a very good foundation for the business application advancement and provider of large-conclude velocity reducers & variators proudly owning to the provincial CZPT technologies analysis centre,the lab of gear velocity reducers, and the base of modern day R&D.

Our products are widely utilised in ceramic market, glass market, woodworking machinery , high voltage swap, food & beverage, packaging & printing, Storage & logistics, hoisting & transportation facilities…etc , and CZPT shine technically give the expert merchandise & provider for the medium and higher-conclude CZPT ers, and CZPT gearboxes are ideal-selling in domestic, and even in overseas , these kinds of as in CZPT pe, North CZPT ica, South CZPT ica, Center CZPT , South Asia, CZPT Asia, Africa…etc.

In the future , CZPT glow will hold the creed of “serving CZPT er, diligence & simplicity, self-criticism, innovation, honesty, teamwork”, and the notion of “top quality creates price” to concentrate on the CZPT ers’ needs and give them the competitive transmission remedy and develop worth for them consistently, and make a high-finish equipment producing business and create a preferred brand name of changing import products and upgrading continually for the end users.

TEAM

Quality Manage

Top quality:Insist on Improvement,Strive for CZPT With the improvement of products production indurstry,buyer by no means satirsfy with the present good quality of CZPT merchandise,on the opposite,wcreate the price of top quality.

Top quality plan:to improve the overall stage in the field of CZPT transmission

Good quality Check out:Steady Enhancement , pursuit of excellence

Quality Philosophy:Top quality generates price

3. Incoming Good quality Manage

To create the AQL appropriate level of incoming material manage, to supply the material for the whole inspection, sampling, immunity. On the acceptance of competent goods to warehousing, substandard items to get return, check, rework, rework inspection accountable for monitoring undesirable, to keep track of the supplier to get corrective steps to prevent recurrence.

four. Process Top quality Management

The producing internet site of the very first examination, inspection and last inspection, sampling in accordance to the specifications of some initiatives, judging the top quality change development located irregular phenomenon of production, and supervise the generation office to increase, eradicate the abnormal phenomenon or point out

5. FQC(Ultimate QC)

After the manufacturing division will total the item, stand in the CZPT er’s situation on the concluded product quality verification, in buy to guarantee the high quality of CZPT er expectations and needs.

six. OQC(Outgoing QC)

Following the item sample inspection to figure out the qualified, allowing storage, but when the completed solution from the warehouse ahead of the official supply of the goods, there is a check, this is called the shipment inspection.Check out material:In the warehouse storage and transfer position to confirm, although confirming the shipping of the merchandise is a product inspection to establish the qualified products.

PACKING

DELIVERY

An AC motor is a typical kind of electric powered motor that is driven by alternating existing. As the most efficient useful motors for daily industrial apps (as well as hobbyist projects, house products, and all other expert gear and customer merchandise), AC motors provide a comparatively successful approach of generating mechanical energy from a easy electrical enter signal.

china Cost R Series Inline Helical Gearbox Reducer with Flange Mounted manufacturers

Solution Description

R Series Inline CZPT cal Gearbox Reducer with Flange Mounted

Features R Collection CZPT cal Equipment Device:

1. Small horizontal deviation of output shaft, compact construction, greatest utilization of housing place, lodging of 2-stage and 3-stage gears in one particular situation.

2. Unitary cast housing with substantial rigidity, increased shaft energy and extended bearing life span.

three. The special-goal CRM Sequence for agitators can stand up to greater axial and radial load.

four. Mounting method: Foot-mounted, flange-mounted.

five. Input manner: Coupled motor, belted motor, enter shaft or link flange.

Technical specs:

one. Lower noise.

2. Sleek managing.

3. CZPT loading potential.

Mounting Variety:

| R(-) |

RF | RS | RFS | RM |

| Foot-mounted | Flange-mounted | Foot-mounted and Shaft In-place | Flange-mounted and shaft input | Specially for stirrer |

Positive aspects:

one. Merchandise positive aspects: CZPT modular style, making all the sequence use much less components, it can conveniently equip electric motor or other driving forces of CZPT varieties.

two. The cabinet applies integral and substantial-energy casting mode, which has high rigidity and vibration resistance functionality.

three. The equipment unit applies lower-carbon alloy metal quenching equipment grinding method and shape-correction technological innovation, creating the goods have greater bearing ability. The procedure is reliable, which can reduce sounds and enhance efficiency. Transmission ratio is divided into information, the scope is wide. Blended type can obtain larger transmission ratio.

four. Equipment unit is proper to be mounted at any place and any angle.

Your benefits:

one. Effective cooling systems.

2. Incredibly robust equipment device housing.

three. Lowered fees and excess weight because of to large CZPT density and finely stepped dimensions.

4. CCW and CW versions may be carried out in a one gear unit edition.

five. Straightforward framework and practical to be mounted and maintained

6. CZPT efficiency:

Solitary-stage greater than ninety six.5% better than 93%, two-stage, a few more than 90%.

7. CZPT effectiveness: Our CZPT models now are in higher load capability as the gears have been redesigned.

eight. CZPT ability of being overloaded: CZPT duty roller bearings for highest toughness and prolonged daily life.

nine. CZPT service life: Daily life of primary components of CZPT (apart from donning components) must not be significantly less than 20, 000 hrs.

Software industries:

The merchandise are extensively used in electrical power, coal, cement, metallurgy, harbor, agriculture, delivery, lifting, atmosphere safety, phase, logistic, weaving, paper producing, light sector, plastics and other regions.

| Rated CZPT |

.18KW~160KW |

| Rated Torque |

Up to 18000N.m |

| Gear Arrangement |

Helical Hardened Gearbox |

| Input CZPT | 50HZ or 60HZ of 4Pole,6Pole and 8pole motor |

| Output CZPT |

.16~1571r/min |

| Ratio |

five~264 (Max:13000) |

Merchandise picture:

Solution application :

Packing & Delivery:

Our organization :

AOKMAN® was founded in 1982, which has much more than 36 a long time in R & D and production of gearboxes, gears, shaft, motor and spare areas.

We can supply the suitable answer for uncountable applications. Our merchandise are extensively utilized in the ranges of metallurgical, steel, mining, pulp and paper, sugar and alcoholic beverages market and CZPT other kinds of equipment with a robust existence in the intercontinental marketplace.

AOKMAN® has become a dependable provider, in a position to provide substantial quality gearboxes.With 36 many years encounter, we guarantee you the utmost reliability and stability for the two solution and providers.

Buyer visiting:

Our Providers:

| Pre-sale providers | 1. Choose gear design. |

| 2.Design and style and manufacture merchandise according to clients’ special necessity. | |

| three.Practice specialized personalized for clientele | |

| Services throughout promoting | 1.Pre-examine and settle for merchandise forward of supply. |

| two. Support consumers to draft solving strategies. | |

| After-sale providers | 1.Assist consumers to get ready for the very first construction scheme. |

| 2. Train the initial-line operators. | |

| 3.Consider initiative to eradicate the trouble swiftly. | |

| 4. Give specialized exchanging. |

FAQ:

1.Q:What sorts of gearbox can you produce for us?

A:Main products of CZPT company: UDL sequence pace variator,RV series CZPT reducer, ATA series shaft mounted gearbox, X,B series gear reducer,

P collection planetary gearbox and R, S, K, and F series CZPT cal-tooth reducer, a lot more

than one hundred types and hundreds of technical specs

2.Q:Can you make as per CZPT drawing?

A: Sure, we provide CZPT ized support for CZPT ers.

three.Q:What is your terms of payment ?

A: 30% CZPT payment by T/T right after signing the deal.70% just before shipping and delivery

four.Q:What is your MOQ?

A: 1 Set

If you are interested in CZPT item, welcome you get in touch with me.

Our team will assistance any need to have you may possibly have.

DC motors use strength from batteries or other making sources that supply a continuous voltage. A DC motor is composed of numerous components, the most well-known of which contain bearings, shafts, and gearboxes or gears. DC motors offer much better velocity variation and control and create much more torque than AC motors. The two types of DC motors include Brushed motors: Brushed motors are 1 of the oldest varieties and are internally commutated motors driven by DC recent. A brushed motor consists of a rotor, brushes, and a shaft. The demand and polarity of the brushes manage the path and pace of the motor. Brushless Motors: In recent many years, brushless motors have grow to be well-known for many apps, primarily because of their efficiency. Brushless motors are built in the same way as brushed motors, minus the brushes of program. Brushless motors also incorporate committed circuitry to management velocity and course. In brushless motors, magnets are mounted about the rotor, an efficiency-boosting configuration.

china shop RV Worm Aluminium Gear Reducer with Input Flange manufacturers

Item Description

RV Worm Aluminium Gear Reducer with Enter Flange

NMRV 571-one hundred fifty worm CZPT with flange and electrical motor

NMRV+NMRV Double Stage Arrangement Reduction Gear Box

RV Sequence Worm Gearbox

worm pace reducer

nmrv CZPT motor

RV Sequence

Which includes RV / NMRV / NRV.

Major Attribute of RV Collection Worm Gearbox

RV collection CZPT reducer is a new-technology merchandise produced by CZPT on the basis of perfecting WJ series products with a compromise of CZPT d technology the two at residence and abroad.

one. CZPT -high quality aluminum alloy, gentle in weight and CZPT -rusting.

two. Big in output torque.

three. Easy operating and reduced sound,durable in dreadful circumstances.

four. CZPT radiation efficiency.

5. CZPT -searching appearance, sturdy in service life and small volume.

six. Suited for omnibearing set up.

Principal CZPT of RV Sequence Worm Gearbox

one. Housing: die-solid aluminum alloy(body dimension: 571 to 090), forged iron(frame measurement: 110 to 150).

2. Worm: 20Crm, carbonization quencher heat treatment method can make the area hardness of CZPT s up to fifty six-sixty two HRX, retain carbonization layer’s thickness between .3 and .5mm following precise grinding.

3. Worm Wheel: wearable stannum bronze alloy.

| SPEED RATIO | 7.5~a hundred |

| OUTPUT TORQUE | <1050NM |

| IN POWER | .09-11KW |

| MOUNTING TYPE | FOOT-MOUNTED FLANGE-MOUNTED |

| When functioning, fantastic load capability, stable running, minimal sound with higher efficiency. | |||||||

| Gear Box’s Utilization Area | |||||||

| 1 | Metallurgy | eleven | Agitator | ||||

| 2 | Mine | twelve | Rotary weeder | ||||

| 3 | Equipment | 13 | Metallurgy | ||||

| 4 | Vitality | 14 | Compressor | ||||

| five | Transmission | 15 | Petroleum sector | ||||

| 6 | Water Conserbancy | 16 | Air CZPT | ||||

| seven | Tomacco | 17 | Crusher | ||||

| eight | Healthcare | 18 | Materials | ||||

| nine | Packing | 19 | Electronics | ||||

| ten | Chemical industry | twenty | Textile indutry | ||||

| … | … | ||||||

| Power | .06kw | .09kw | .12kw | .18kw | .25kw | .37kw | .55kw |

| .75kw | one.1kw | 1.5kw | 2.2kw | 3kw | 4kw | five.5kw | |

| 7.5kw | 11kw | 15kw | |||||

| Torque | 2.6N.m-3000N.m | ||||||

| Ratio | 7.5-100, the double gearbox is a lot more | ||||||

| Colour | Blue, Silver or as CZPT ers’ need | ||||||

| Material | Iron or Aluminium | ||||||

| Packing | Carton with Plywood Scenario or as clients’ requirement | ||||||

| Variety | RV571 | RV030 | RV040 | RV050 | RV063 | RV075 | RV090 |

| Excess weight | .7kg | one.3kg | two.3kg | three.5kg | 6.2kg | 9kg | 13kg |

| Variety | RV110 | RV130 | RV150 | ||||

| Fat | 35kg | 60kg | 84kg | ||||

| Mounting Strategies | Foot Installation | Flange Installation | |||||

| For CZPT mortor or double enter/output shafts can be outfitted | |||||||

Solution photo:

Structure:

Certification:

Packing & Shipping and delivery:

Our firm :

AOKMAN® was started in 1982, which has more than 36 many years in R & D and producing of gearboxes, gears, shaft, motor and spare elements.

We can provide the suitable remedy for uncountable apps. Our merchandise are broadly employed in the ranges of metallurgical, steel, mining, pulp and paper, sugar and alcohol market place and CZPT other varieties of equipment with a strong existence in the worldwide market place.

AOKMAN® has grow to be a reliable provider, in a position to source higher top quality gearboxes.With 36 a long time expertise, we assure you the utmost trustworthiness and security for equally merchandise and companies.

Client visiting:

FAQ:

one.Q:What varieties of gearbox can you produce for us?

A:Major goods of CZPT firm: UDL collection speed variator,RV series CZPT reducer, ATA series shaft mounted gearbox, X,B collection equipment reducer,

P sequence planetary gearbox and R, S, K, and F series CZPT cal-tooth reducer, more

than 1 hundred models and 1000’s of technical specs

2.Q:Can you make as per CZPT drawing?

A: Sure, we supply CZPT ized service for CZPT ers.

three.Q:What is your phrases of payment ?

A: thirty% CZPT payment by T/T soon after signing the agreement.70% just before supply

four.Q:What is your MOQ?

A: 1 Set

Get in touch with:

Welcome you contace me if you are intrigued in CZPT item.

Our staff will help any need to have you may possibly have.

These NEMA c-aircraft reducers are equipment toughness, routine maintenance-free, and can be mounted in any orientation with a slip fit “O” ring design and style. Accessible in lower to high reduction ratios, flange mount or base mount variations, correct angle or hollow shaft correct angle variations. Put in NEMA C-Encounter AC motors, brushless DC motors, and brushed DC motors. For 1/2 HP to 3 HP Motors NEMA 56C, 140TC, and 180TC Input Flange Inline Helical Equipment Reducers Appropriate Angle Hypoid Gear Reducers

in Lusaka Zambia sales price shop near me near me shop factory supplier Atg High Precision Flange Planetary Reducer for Medical Equipment manufacturer best Cost Custom Cheap wholesaler

It has recognized steady cooperation with a lot of effectively recognized universities and institutes in china these kinds of as, Zhejiang College, Jilin College, Specialized committee of nationwide chain push normal, Institute of countrywide chain generate, Zhejiang application engineering content institute, Huhan substance security institute and it cooperated to identified China 1st Car chain institute with National chain generate institute. a specialised provider of a total assortment of chains, sprockets, gears, gear racks, V-belts, couplings and reducers. Hangzhou EPG Co.,Ltd. , was established in November, 1997. With its 5 wholly owned subsidiaries. PGE Series

Merchandise Functions:

(one) Reduced Sound:UnEPT65db.

(2) Reduced Backlash:Backlash is unEPT3 arcmin . Backlash for 2-phase pace reduction is with in five arcmin.

(3) High Effectiveness:1-stage up to 95% or a lot more,two-phase up to 92% or more.

(four) High Input Speed:Input velocity allows for up to 8000RPM.

(5) Substantial Torque:Large torque output than that of typical planetary EPT EPTs

(six) Maintenance-Totally free:Lower grease dress in,can be life span lubrication

(seven) Large Velocity Reduction Ratio:Velocity ratio is above 1/a thousand.

Gain:

Usage:

- Aerospace,army industry.

- Health care overall health,digital details industry.

- Industry robots,Generation EPT,CNC EPT tool producing industry.

- EPT,Textile,EPT,Food,EPTlurgical.

- EPT safety engineering,Warehouse EPT business.

Product ILLUMINATE:

Equipment BOX Efficiency Information:

| MODUL NO. | Phase | RATIO sup1 | PGE42 | PGE60 | PGE90 | PGE120 | PGE160 | |

| Rated output torque T2N | Nm | 1 | 3 | 14 | 39 | 104 | 215 | 423 |

| four | twelve | 31 | eighty five | 176 | 364 | |||

| five | fourteen | 39 | 104 | 215 | 423 | |||

| 7 | 12 | 33 | 91 | 195 | 358 | |||

| 8 | 10 | 33 | eighty | 160 | 330 | |||

| ten | 9 | 28 | seventy five | 210 | 320 | |||

| 12 | fourteen | 39 | 104 | 215 | 423 | |||

| 15 | fourteen | 39 | 104 | 215 | 423 | |||

| 20 | twelve | 31 | eighty five | 176 | 364 | |||

| 25 | fourteen | 39 | 104 | 215 | 423 | |||

| 30 | – | – | 104 | 215 | 423 | |||

| 35 | 14 | 39 | 104 | 215 | 423 | |||

| forty | fourteen | 39 | 104 | 215 | 423 | |||

| fifty | – | – | 104 | 215 | 423 | |||

| 70 | – | – | 104 | 215 | 423 | |||

| 100 | nine | 28 | seventy five | 210 | 320 | |||

| three~100 | three moments of Nominal Output Torque | |||||||

| three~a hundred | 450 | 4,000 | 3,600 | three,000 | two,500 | |||

| three~100 | 800 | 6,000 | 6,000 | 4,800 | 3,600 | |||

| EPT Backlash | arcmin | 1 | three~ten | le8 | ||||

| 2 | 12~a hundred | le10 | le10 | le8 | le8 | le8 | ||

| Torsional stiffness | Nm/arcmin | 1,two | 3~100 | 1 | two | 7 | 15 | 66 |

| Max.radial force F2rB sup2 | N | 1,2 | 3~100 | 300 | 680 | 1750 | 3080 | 6520 |

| one,two | 3~one hundred | a hundred and fifty | 340 | 875 | 1540 | 3260 | ||

| Provider life | hr | one,2 | three~100 | twenty,000* | ||||

| one | three~ten | ge97 | ||||||

| two | 12~a hundred | ge94 | ||||||

| Excess weight | kg | 1 | 3~ten | 1 | 2 | four | 8 | 18 |

| 2 | twelve~one hundred | 1 | two | five | 11 | twenty five | ||

| Running temperature | ordmC | one,2 | three~100 | -10 ordmC~ ninety ordmC | ||||

| Lubrication | 1,two | three~100 | Artificial lubricating oil | |||||

| Defense stage | 1,two | 3~a hundred | IP65 | |||||

| 1,2 | 3~one hundred | Any direction | ||||||

| Sound degree(n1=3000rpm) | dB | one,2 | three~100 | le68 | le70 | le72 | le74 | le75 |

Define DIMENSION:

Company See:

HangEPT EPEPTn De Yi Electrical Co.,Ltd. is a subsidiary of EPTiwan Jun Yi EPTry. Jun Yi EPTry was established in March 1972. The organization EPTizes in the layout, deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment and manufacturing of high-tech a variety of EPTed motors and helical EPT EPTs, worm and worm EPT EPTs and planetary EPTs. Our merchandise offered to more than thirty countries close to the world and get good status and several awards in the overEPT industry for several many years. In modern years, to accomplish EPT production and offer exceptional provider,we established up subsidiary of production of planetary EPT EPT in EPT.

Background:

1972:EPTiwan Jun Yi EPTry is launched.

1989:It estabEPTd a overEPT department company ATRUMP EPTRY INC in Los Angeles

1995:Pass the ISO9002 Commodity certification.

2003:Pass the ISO9001 high quality certification and the European CE stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd take a look at which enabled the merchandise to be offered in Europe

2013:The organization established up subsidiary in EPT to accomplish EPT manufacturing.

Manufacturing unit:

Wisdom Created IN ATG,Knowledge THE EPT.

Equipment:

INSPECTION Tools:

FAQ:

(1) Can I be your agent?

Of course, welcome to deep cooperation. We have massive promotion of ATG model in the marketplace now. For the details please make contact with me.

(2) Is OEM obtainable?

Yes, OEM is available. We have professional designer to assist your brand name promotion.

(three) How can I get a sample to verify your high quality?

Following cost confirmation, you can require for samples to check out our good quality. Totally free for the samples, but you need to pay for the freight.

(four)What is your high quality promise?

We have different types of products which can satisfy different good quality stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd.

Our QC division will test goods prior to transport. We have 100% quality assure to clients. We will be accountable for any quality difficulty.

(five) How about the delivery time?

The shipping and delivery time is depending on the items and the quantity. But EPTly, the shipping and delivery time for a container is about one particular thirty day period.

Welcome to our company.

If any difficulty, truly feel free of charge to leave message on the bottom of this webpage.