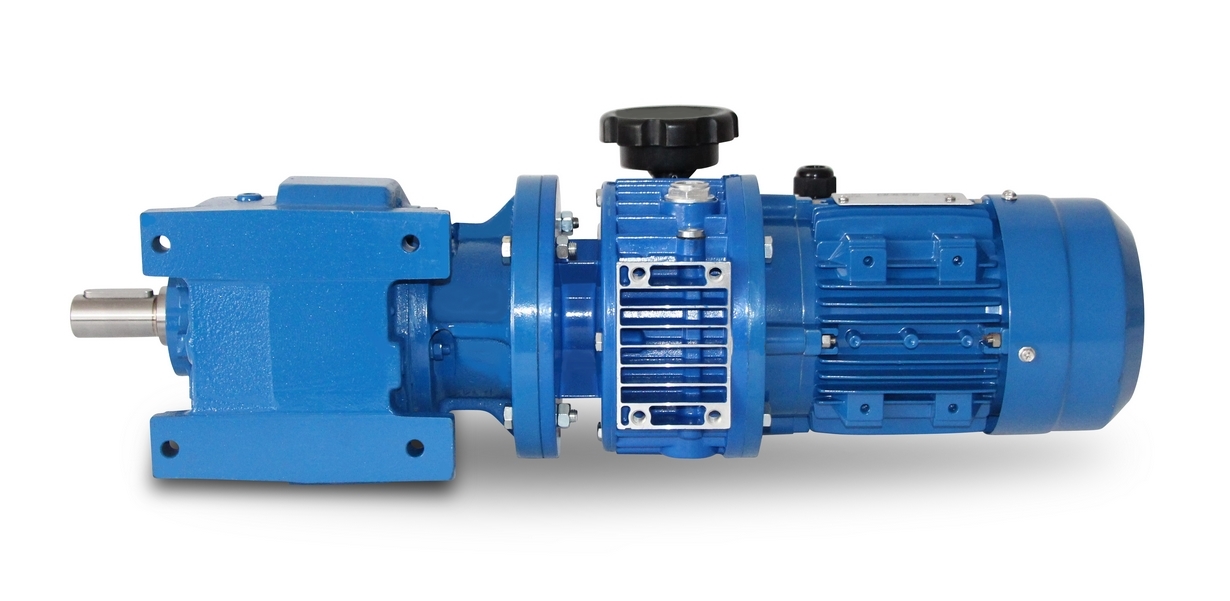

Product Description

Starshine Drive S Series Helical-Worm Geared Motor

Features:

- High efficiency: 75%-80%;

- High technology: the helical gear and a worm gear combined with an integrated transmission to improve the torque and efficiency.

- High precision: the gear is made of high-quality alloy steel forging, carbonitriding and hardening treatment, grinding process to ensure high precision and stable running

- High interchangeability: highly modular, serial design, strong versatility and interchangeability.

Technical parameters

| Type | Old Type | Output Torque | Output Shaft Dia. |

| SHS37 | S37 | 90N.m | φ20 |

| SHS47 | S47 | 170N.m | φ25 |

| SHS57 | S57 | 300N.m | φ30 |

| SHS67 | S67 | 520N.m | φ35 |

| SHS77 | S77 | 1270N.m | φ45 |

| SHS87 | S87 | 2280N.m | φ60 |

| SHS97 | S97 | 4000N.m | φ70 |

About CHINAMFG Drive

ZheJiang CHINAMFG Drive Co.,Ltd(Starshine) have a strong technical force with over 350 employees at present, including over 30 engineering technicians, 30 quality inspectors, covering an area of 80000 square CHINAMFG and kinds of advanced processing machines and testing equipments. We have a good foundation for the industry application development and service of high-end speed reducers & variators owning to the provincial engineering technology research center,the lab of gear speed reducers, and the base of modern R&D.

Our products are widely used in ceramic industry, glass industry, woodworking machinery , high voltage switch, food & beverage, packaging & printing, Storage & logistics, hoisting & transportation facilities…etc , and CHINAMFG technically provide the professional product & service for the medium and high-end customers, and our gearboxes are best-selling in domestic, and even in abroad , such as in Europe, North America, South America, Middle East, South Asia, Southeast Asia, Africa…etc.

In the future , CHINAMFG will hold the creed of “serving customer, diligence & simplicity, self-criticism, innovation, honesty, teamwork”, and the concept of “quality creates value” to focus on the customers’ requirements and provide them the competitive transmission solution and create value for them constantly, and make a high-end equipment manufacturing industry and create a preferred brand of replacing import products and upgrading continuously for the end users.

Team

Quality Control

Quality:Insist on Improvement,Strive for CHINAMFG With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of CHINAMFG

Quality Philosophy:Quality creates value

3. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection; responsible for tracking bad, to monitor the supplier to take corrective measures to prevent recurrence.

4. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend; found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state

5. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer’s position on the finished product quality verification, in order to ensure the quality of customer expectations and needs.

6. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the product is a product inspection to determine the qualified products.

Packing

Delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction |

| Layout: | Helical Worm Gear |

| Samples: |

US$ 139.3/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does the size and power rating of variator motors impact their performance?

The size and power rating of variator motors have a significant impact on their performance. Here’s a detailed explanation of how these factors influence motor performance:

- Torque Output: The size and power rating of a variator motor directly affect its torque output. Generally, larger and higher-rated motors can deliver higher torque levels, allowing them to handle heavier or more demanding loads. A motor with higher torque capability can provide better acceleration, overcome resistance, and maintain stable operation under varying load conditions.

- Speed Range: The size and power rating of the motor also influence its speed range. Motors with higher power ratings can typically achieve a broader speed range, allowing for more flexibility in matching the motor’s speed to the application’s requirements. Smaller motors may have a more limited speed range, which can impact their suitability for certain applications that require a wide range of speeds.

- Overload Capacity: Larger and higher-rated variator motors generally have a higher overload capacity. They can handle temporary increases in load or momentary peak demands without experiencing significant performance degradation or overheating. This makes them suitable for applications with intermittent or cyclical loads, where occasional high torque requirements may arise.

- Efficiency: The size and power rating of a motor can impact its efficiency. In general, larger motors tend to have higher efficiencies, especially when operating near their rated capacity. Higher efficiency means less energy loss as heat and improved overall energy utilization. It’s important to select a motor with an appropriate power rating to ensure efficient operation while avoiding oversized motors that may operate at low efficiency levels.

- Physical Dimensions: The size of a variator motor directly affects its physical dimensions and weight. Larger motors typically have larger physical footprints and may be heavier. The physical dimensions of the motor can impact its installation requirements, space availability, and integration into the overall system design. It’s important to consider the available space and mounting requirements when selecting a motor of a suitable size.

- Heat Dissipation: The size and power rating of a motor influence its heat dissipation capabilities. Higher-rated motors generally generate more heat during operation, and larger motors have a larger surface area for heat dissipation. Adequate heat dissipation is crucial to prevent overheating and ensure the motor’s long-term reliability. It’s important to consider the motor’s cooling requirements, such as ventilation or cooling mechanisms, to maintain optimal operating temperatures.

- Cost: The size and power rating of a variator motor can impact its cost. Generally, larger and higher-rated motors tend to be more expensive than smaller ones due to the increased materials, manufacturing complexity, and performance capabilities. It’s important to balance the motor’s size, power rating, and associated cost with the specific requirements and budget of the application.

In summary, the size and power rating of variator motors significantly influence their performance in terms of torque output, speed range, overload capacity, efficiency, physical dimensions, heat dissipation, and cost. It’s crucial to carefully consider these factors when selecting a motor to ensure it meets the requirements of the application and delivers optimal performance and reliability.

How do variator motors contribute to energy efficiency in manufacturing processes?

Variator motors play a significant role in improving energy efficiency in manufacturing processes. Here’s a detailed explanation:

Variator motors, also known as variable speed motors or adjustable speed drives, offer the ability to adjust the motor’s speed and torque according to the requirements of the manufacturing process. This flexibility provides several ways in which variator motors contribute to energy efficiency:

- Optimized Process Control: By varying the motor’s speed, variator motors allow manufacturers to precisely match the motor’s output to the process requirements. This optimization eliminates the need for constant full-speed operation, which can result in unnecessary energy consumption. Instead, the motor can run at reduced speeds during periods of lower demand, resulting in energy savings.

- Reduced Mechanical Losses: Traditional motors operating at fixed speeds often use mechanical devices, such as throttling valves or dampers, to control the process flow or pressure. These devices introduce additional mechanical losses that consume energy. With variator motors, the motor speed can be adjusted directly, eliminating the need for such mechanical control devices and reducing energy losses associated with them.

- Efficient Motor Operation: Variator motors are designed to operate efficiently over a broad range of speeds. Unlike fixed-speed motors that may experience reduced efficiency at lower speeds, variator motors can maintain high efficiency even at reduced speeds. This efficiency is achieved through advanced motor designs, improved motor control algorithms, and the use of technologies like permanent magnet motors or synchronous reluctance motors.

- Power Factor Correction: Variator motors can incorporate power factor correction (PFC) techniques to improve the power factor of the motor. Power factor is a measure of how effectively the motor utilizes the supplied electrical power. By improving the power factor, variator motors reduce the reactive power drawn from the power grid, resulting in lower electricity bills and reduced strain on the electrical distribution system.

- Energy Recovery: Some variator motors can feature regenerative capabilities, allowing them to recover and feed excess energy back into the power grid or reuse it within the manufacturing process. For example, in applications where the motor decelerates or operates as a generator, the energy generated can be fed back into the grid or used to power other equipment, further enhancing energy efficiency.

- Process Optimization: Variator motors offer the advantage of precise control over motor speed and torque. This control can be utilized to optimize manufacturing processes, such as matching the motor speed to the optimal speed for material handling, mixing, or other process requirements. By fine-tuning the motor operation, variator motors enable improved process efficiency, reduced material waste, and energy savings.

By leveraging the flexibility and control offered by variator motors, manufacturers can achieve substantial energy savings in their production processes. The specific energy-saving potential will depend on the application, process requirements, and the extent to which the motor’s speed and torque can be optimized. It’s important to consult with motor manufacturers, engineers, and energy experts to assess the suitability and potential energy savings of variator motors in specific manufacturing applications.

Are there specific types of variator motors designed for certain tasks or environments?

Yes, there are specific types of variator motors that are designed to suit certain tasks or operate effectively in specific environments. Here are some examples:

- Variable Frequency Drives (VFDs): VFDs are a type of variator motor designed for electric motors. They are widely used in various industrial applications and are particularly suited for tasks that require precise speed control. VFDs allow for adjustable speed by varying the frequency of the electrical power supplied to the motor. They are commonly utilized in applications such as pumps, fans, conveyors, and machine tools.

- Hydraulic Variator Motors: Hydraulic variator motors are designed for applications that require high torque and ruggedness. They are commonly used in heavy machinery, construction equipment, and industrial processes where hydraulic power is readily available. Hydraulic variators control the motor speed by adjusting the flow rate and pressure of the hydraulic fluid, allowing for variable speed operation in demanding environments.

- Variable Transmission Systems: Some variator motors are designed with variable transmission systems, such as mechanical gearboxes. These motors are suitable for applications that require adjustable speed through gear ratio changes. They are commonly used in automotive applications, industrial machinery, and equipment that benefit from mechanical speed control mechanisms.

- Electronically Controlled Variator Motors: Certain variator motors incorporate advanced electronic control systems to achieve variable speed control. These motors are often used in automation and robotics applications, where precise and programmable speed control is essential. The electronic control systems allow for integration with other control systems and enable sophisticated control algorithms to optimize performance.

- Explosion-proof Variator Motors: In hazardous environments where the presence of flammable gases or dust is a concern, explosion-proof variator motors are designed to meet strict safety standards. These motors are constructed with special enclosures, seals, and components that prevent the ignition of hazardous substances. They are commonly used in industries such as oil and gas, chemical processing, and mining.

These are just a few examples of specific types of variator motors designed for particular tasks or environments. It’s important to select the appropriate variator motor that meets the requirements of the specific application, taking into consideration factors such as speed range, load characteristics, environmental conditions, safety considerations, and regulatory compliance.

editor by CX 2024-05-15

china price Helical Geared Motor Gear Reducer Foot Mounted for Conveyor Machine manufacturers

Solution Description

Helical Geared CZPT Equipment Reducer Foot Mounted for CZPT CZPT

Merchandise Description

suspended cranes inline CZPT cal gearbox

SGR helical geared motor entire body use the large diploma of modularity cast iron, the equipment and the axis use the substantial top quality alloy steel in purchase to the precision forging, the helical gearbox though the strict heat treament procedure, guarantees helical gearbox‘s intensity and the rigidity. inline CZPT cal gearbox configure motor with flange or foot ,

helical gearbox design use modular compose with other reducers and variator, get a massive minimize ratio drive and variation. Therefore inline CZPT cal gearbox producer SGR ‘s helical equipment motor applied to a lot of industrial area, this sort of as CZPT lurgical, mines, lifting, transportation, petrochemical, building, textile, pharmaceutical, foodstuff, environmental, mild electric powered, plastic equipment, paper, parking gear and so on.

You can download inline CZPT cal gearbox catalogue from proper button

Specialized information:

| Model | Shaft Dia. | Center Top | Output Flange Dia. | Electrical power | Ratio | Permitted Torque | Fat |

| Strong (mm) | (mm) | (mm) | (kw) | (Nm) | (KGS) | ||

| R37 | 25k6 | 90h13 | 120/a hundred and sixty | .twelve~.75 | 5~136 | a hundred and fifty | 10 |

| R47 | 30k6 | 115h13 | one hundred sixty/two hundred | .25~2.two | five~173 | three hundred | 15 |

| R57 | 35k6 | 115h13 | two hundred/250 | one.18~5.5 | 5~173 | 400 | 21 |

| R67 | 35k6 | 130h13 | two hundred/250 | .37~7.five | five~170 | 500 | 27 |

| R77 | 40k6 | 140h13 | 250/three hundred | .55~11 | 5~192 | 750 | 35 |

| R87 | 50k6 | 180h13 | three hundred/350 | .75~eighteen.5 | 5~192 | 1250 | 65 |

| R97 | 60m6 | 225h13 | 350/450 | one.5~30 | five~197 | 2400 | a hundred and twenty |

| R107 | 70m6 | 250h13 | 350/450 | 2.2~45 | five~197 | 3600 | a hundred sixty five |

| R137 | 90m6 | 315h13 | 450/550 | four~55 | 5~197 | 6600 | 255 |

| R147 | 110m6 | 355h13 | 450/550 | 7.5~ninety | 5~195 | 10700 | 370 |

| R167 | 120m6 | 425h13 | 550/660 | 11~132 | 8~186 | 14800 | seven hundred |

| R187 | 160m6 | 510h13 | 660/770 | fifteen~160 | 8~186 | 28000 | 1500 |

| Remark: the weight with out oil and motor, shaft and flange input add ten%. | |||||||

Attribute:

| Important Attributes: (5 factors)*1* |

|

FAQ:

1.Are you a manufacturing unit or trader ?

We are a expert manufacturing unit which has 20 several years heritage specialized in gear transmission .

2.MOQ:

Our MOQ is 1pcs. However there is one particular dealing with value $150 for the solitary get which significantly less than $3000.00

3. Guarantee

Our guarantee is 12months

four. Payment time period

100% T/T in CZPT and LC at sight .

5. Do you take CZPT ization ?

Yes.SGR have powerful R&D team, we can give CZPT izable service according to demands.

six. Packing

Normally we use standard export plywood situation to arrange the cargo .

seven. Supply time

In regular ,time of supply is 30days after obtaining the prepayment .

8. What sorts of certification do you use ?

DNV-ISO9001:2008, SGS,CE and so on, And new goods patent.

9. What kinds of inspection you do prior to shipment ?

We do temperature check, sounds, and oil leak inspection and commissioning before shipment.

10.How do you solve if the production have issue ?

Mostly, we do not need to have CZPT er send out the items again to us. Since the cost is very substantial, if there satisfies a problem,we firstly ask for the pictures for broken components. And base on the pictures, we can have a simple notion for the defect cause. Our assure is 12 months, if in the course of the assure, we can supply repair .

AC motors and equipment motors incorporate one-phase motors for solitary-period AC energy and three-stage motors for a few-section AC energy. A single-period motor basically wants to be linked to a solitary-section electricity provide via the provided capacitors to function. 3-section motors do not need capacitors. You simply join the motor immediately to the a few-period AC energy source. Dongfang Electrical gives a vast assortment of AC motors and equipment motors Continuous or variable velocity AC motors are offered with single or three-phase equipment and electromagnetic braking choices

china supplier S Series Foot Mounted Solid Shaft Helical-Worm Geared Reducer with Inline Motor manufacturers

Merchandise Description

Starshine CZPT S Collection CZPT cal-Worm Geared CZPT

Characteristics:

- High efficiency: seventy five%-80%

- Substantial technology: the helical equipment and a CZPT combined with an built-in transmission to improve the torque and performance.

- Higher precision: the gear is produced of substantial-quality alloy steel forging, carbonitriding and hardening treatment, grinding procedure to ensure high precision and steady running

- Substantial interchangeability: very modular, serial design, sturdy versatility and interchangeability.

Technological parameters

| Variety | Outdated Type | Output Torque | Output Shaft Dia. |

| SHS37 | S37 | 90N.m | φ20 |

| SHS47 | S47 | 170N.m | φ25 |

| SHS57 | S57 | 300N.m | φ30 |

| SHS67 | S67 | 520N.m | φ35 |

| SHS77 | S77 | 1270N.m | φ45 |

| SHS87 | S87 | 2280N.m | φ60 |

| SHS97 | S97 | 4000N.m | φ70 |

About CZPT glow CZPT

ZheJiang CZPT glow CZPT Co.,Ltd(Starshine) have a strong complex drive with over 350 personnel at current, which includes over thirty CZPT professionals, 30 high quality inspectors, masking an location of 80000 sq. meters and varieties of CZPT d processing equipment and testing equipments. We have a good basis for the sector software advancement and support of substantial-stop pace reducers & variators possessing to the provincial CZPT technological innovation analysis centre,the lab of gear velocity reducers, and the foundation of contemporary R&D.

Our products are widely utilized in ceramic business, glass business, woodworking equipment , high voltage switch, food & beverage, packaging & printing, Storage & logistics, hoisting & transportation facilities…etc , and CZPT glow technically supply the expert product & provider for the medium and large-finish CZPT ers, and CZPT gearboxes are greatest-promoting in domestic, and even in overseas , such as in CZPT pe, North CZPT ica, South CZPT ica, Middle CZPT , South Asia, CZPT Asia, Africa…etc.

In the potential , CZPT shine will maintain the creed of “serving CZPT er, diligence & simplicity, self-criticism, innovation, honesty, teamwork”, and the principle of “top quality produces worth” to concentrate on the CZPT ers’ requirements and provide them the competitive transmission solution and produce value for them continuously, and make a high-end tools producing market and develop a preferred brand name of replacing import merchandise and upgrading repeatedly for the conclude end users.

Crew

Quality Manage

Good quality:Insist on Enhancement,Attempt for CZPT With the advancement of gear production indurstry,buyer in no way satirsfy with the present high quality of CZPT goods,on the contrary,wcreate the value of good quality.

High quality coverage:to enhance the all round level in the field of CZPT transmission

Good quality See:Continuous Enhancement , pursuit of excellence

Good quality Philosophy:Quality creates benefit

3. Incoming High quality Control

To set up the AQL acceptable amount of incoming material management, to supply the substance for the total inspection, sampling, immunity. On the acceptance of competent merchandise to warehousing, substandard items to get return, verify, rework, rework inspection responsible for tracking poor, to keep track of the supplier to consider corrective measures to stop recurrence.

4. Procedure High quality Control

The production website of the very first examination, inspection and final inspection, sampling in accordance to the specifications of some projects, judging the top quality alter trend identified abnormal phenomenon of manufacturing, and supervise the creation section to improve, get rid of the irregular phenomenon or state

5. FQC(Ultimate QC)

Right after the producing office will full the merchandise, stand in the CZPT er’s place on the finished merchandise quality verification, in get to make sure the high quality of CZPT er anticipations and wants.

six. OQC(Outgoing QC)

After the item sample inspection to figure out the competent, allowing storage, but when the concluded solution from the warehouse just before the official shipping and delivery of the goods, there is a examine, this is known as the cargo inspection.Check out content material:In the warehouse storage and transfer position to confirm, while confirming the supply of the solution is a item inspection to determine the competent items.

Packing

Delivery

These NEMA c-plane reducers are gear strength, upkeep-free, and can be installed in any orientation with a slip suit “O” ring design. Offered in lower to large reduction ratios, flange mount or base mount styles, correct angle or hollow shaft correct angle versions. Put in NEMA C-Face AC motors, brushless DC motors, and brushed DC motors. For 1/2 HP to 3 HP Motors NEMA 56C, 140TC, and 180TC Enter Flange Inline Helical Gear Reducers Correct Angle Hypoid Gear Reducers

china sales R97 Helical Geared Motor Gear Reducer Foot Mounted for Conveyor Machine manufacturers

Product Description

Item Description

suspended cranes inline CZPT cal gearbox

SGR helical geared motor physique use the higher diploma of modularity forged iron, the gear and the axis use the large high quality alloy metal in order to the precision forging, the helical gearbox though the rigid heat treament process, guarantees helical gearbox‘s depth and the rigidity. inline CZPT cal gearbox configure motor with flange or foot ,

helical gearbox design use modular compose with other reducers and variator, get a huge lessen ratio push and variation. Therefore inline CZPT cal gearbox manufacturer SGR ‘s helical gear motor applied to many industrial location, this sort of as CZPT lurgical, mines, lifting, transportation, petrochemical, construction, textile, pharmaceutical, food, environmental, light-weight electric, plastic equipment, paper, parking gear and so on.

You can download inline CZPT cal gearbox catalogue from correct button

Complex information:

| Model | Shaft Dia. | Middle Top | Output Flange Dia. | Electricity | Ratio | Permitted Torque | Fat |

| Solid (mm) | (mm) | (mm) | (kw) | (Nm) | (KGS) | ||

| R37 | 25k6 | 90h13 | one hundred twenty/a hundred and sixty | .12~.75 | 5~136 | one hundred fifty | 10 |

| R47 | 30k6 | 115h13 | a hundred and sixty/200 | .twenty five~2.two | 5~173 | 300 | fifteen |

| R57 | 35k6 | 115h13 | 200/250 | one.eighteen~5.five | 5~173 | 400 | 21 |

| R67 | 35k6 | 130h13 | two hundred/250 | .37~7.five | 5~a hundred and seventy | five hundred | 27 |

| R77 | 40k6 | 140h13 | 250/three hundred | .55~11 | five~192 | 750 | 35 |

| R87 | 50k6 | 180h13 | 300/350 | .seventy five~eighteen.five | 5~192 | 1250 | sixty five |

| R97 | 60m6 | 225h13 | 350/450 | 1.5~30 | 5~197 | 2400 | 120 |

| R107 | 70m6 | 250h13 | 350/450 | two.2~45 | 5~197 | 3600 | 165 |

| R137 | 90m6 | 315h13 | 450/550 | 4~fifty five | five~197 | 6600 | 255 |

| R147 | 110m6 | 355h13 | 450/550 | 7.5~90 | five~195 | 10700 | 370 |

| R167 | 120m6 | 425h13 | 550/660 | 11~132 | 8~186 | 14800 | seven hundred |

| R187 | 160m6 | 510h13 | 660/770 | fifteen~160 | eight~186 | 28000 | 1500 |

| Remark: the excess weight without having oil and motor, shaft and flange input insert ten%. | |||||||

Characteristic:

| Crucial Functions: (5 details)*1* |

|

Creation pictures:

Packing Photographs :

Manufacturing facility

———————————————————————————————————————————————

FAQ:

1.Are you a manufacturing unit or trader ?

We are a professional manufacturing unit which has twenty many years heritage specialized in gear transmission .

two.MOQ:

Our MOQ is 1pcs. However there is one particular dealing with cost $150 for the one get which considerably less than $3000.00

3. Guarantee

Our warranty is 12months

4. Payment phrase

a hundred% T/T in CZPT and LC at sight .

five. Do you acknowledge CZPT ization ?

Indeed.SGR have robust R&D group, we can offer CZPT izable service according to needs.

six. Packing

Typically we use common export plywood situation to prepare the shipment .

seven. Delivery time

In typical ,time of supply is 30days right after getting the prepayment .

8. What varieties of certification do you use ?

DNV-ISO9001:2008, SGS,CE etc, And new merchandise patent.

9. What varieties of inspection you do before shipment ?

We do temperature check, sound, and oil leak inspection and commissioning just before cargo.

ten.How do you fix if the generation have dilemma ?

Largely, we don’t want CZPT er send out the items back to us. Simply because the price is really substantial, if there fulfills a problem,we firstly ask for the photos for damaged components. And foundation on the photographs, we can have a basic concept for the defect reason. Our assure is 12 months, if for the duration of the guarantee, we can provide mend .

Polyphase motors can be either two-period or three-period motors. They perform like solitary-period induction motors, but equally one-section and polyphase motors operate on a rotating magnetic area. Their rotating magnetic fields are generated by two- or a few-section currents passing by means of two or a lot more sets of coils. The rotating magnetic field produces torque. Polyphase motors are utilised in apps that demand high electrical power, such as the power drive of compressors, hydraulic pumps, air conditioning compressors, and irrigation pumps.

china supplier Foot Mounted Parallel Shaft Helical Gearbox Geared Motor with Hollow Shaft and Shrink Disk manufacturers

Item Description

Solution Description

TF Series CZPT cal gearbox can be connected respectively with motors such as IEC common motor, brake motor, explosion-evidence motor, frequency motor, servo motor .It can be connect discretionary(foot or flange) and use multi-mounting positions accordingly. is widely used in textile, foodstuff, beverage,tobacco, logistics industrial fields,and many others.

Merchandise Characteristics

- Modular building

- High effectiveness

- Specific grinding, reduced noise

- Compact structural style

- Univeral mounting

- Powerful Solid iron housing

- Carbonize and grinding hardened gears, resilient

- Multi-structure, can be blended in diverse kinds to meet CZPT transmission problem

Structure:

1.Foot mounted

2.Flange Mounted

3.Shaft Mounted

Detailed Pictures

Item Parameters

| Measurement | Output Shaft | Power(KW) | Ratio | Max. Torque(Nm) | |

| Sound Shaft | Hollow Shaft | ||||

| TF38 | 25mm | 30mm | .18~3. | 3.seventy seven~128.fifty one | 200 |

| TF48 | 30mm | 35mm | .eighteen~3. | four.ninety nine~one hundred ninety.seventy six | 400 |

| TF58 | 35mm | 40mm | .18~5.five | 5.eighteen~199.70 | 600 |

| TF68 | 40mm | 40mm | .18~5.five | three.ninety seven~228.ninety nine | 820 |

| TF78 | 50mm | 50mm | .37~eleven | four.28~281.71 | 1500 |

| TF88 | 60mm | 60mm | .seventy five~22 | four.twelve~270.sixty eight | 3000 |

| TF98 | 70mm | 70mm | 1.1~30 | three.87~276.77 | 4300 |

| TF108 | 90mm | 90mm | 2.2~45 | 5.03~254.40 | 7840 |

| TF128 | 110mm | 100mm | seven.5~ninety | 4.sixty eight~a hundred and seventy.83 | 12000 |

| TF158 | 120mm | 120mm | eleven~200 | 11.ninety two~267.forty three | 18000 |

Define Dimension:

Firm Profile

About CZPT business:

Gele Transmission is a skilled gearbox and motor manufacturer built-in analysis, manufacture and revenue provider. We have exceptional solution collection, supply CZPT ized provider and professional picking information.Currently we largely have :NMRV/NMRW CZPT box/GRC inline mini CZPT cal gearbox/GKM/GKB hypoid CZPT cal gearbox/G2/G3 CZPT cal geared motor-helical gearbox/R/K/F/S sequence CZPT cal gearbox /IE1 IE2 three stage/solitary section electric powered motor/UDL Variator.Our gearboxes are broadly applied for CZPT industrial fields such as foodstuffs, ceramics, packing, substances, pharmacy, plastics, paper- creating, development machinery, metallurgic mine, environmental protection CZPT , and all sorts of computerized lines, and assembly traces.With CZPT supply time, sturdy technical support, outstanding following-revenue support, CZPT d creating facility and screening tools, CZPT merchandise offer well with a very good reputation the two at residence and overseas. We have CZPT ers from CZPT Asia, CZPT pe, The Center CZPT , South CZPT ica, South Africa.Our intention is to create and innovate a lot more substantial performance transmission gearboxes. CZPT Transmission warmly welcome CZPT ers both at house and overseas to get in touch with us for cooperation and generate a vivid foreseeable future.

Packing info:Plastic Luggage+Cartons+Wooden Cases , or on ask for

We participate Germany Hannver Exhibition-ZheJiang PTC Honest-Turkey Win Eurasia

Logistics

We can dispatch items by sea, by teach, by air in accordance to CZPT er instruction

Soon after Income Services

1.Routine maintenance Time and Guarantee:Within a single yr following acquiring products.

2.Other Support: Like modeling choice manual, set up information, and difficulty resolution guide, etc.

FAQ

one.Q:Can you make as for each CZPT er drawing?

A: Indeed, we supply CZPT ized service for CZPT ers accordingly. We can use CZPT er’s nameplate for gearboxes.

two.Q:What is your phrases of payment ?

A: thirty% deposit ahead of manufacturing,stability T/T prior to supply.

3.Q:Are you a trading business or maker?

A:We are a manufacurer with CZPT d gear and experienced employees.

four.Q:What is actually your creation ability?

A:8000-9000 PCS/Month

5.Q:Totally free sample is CZPT or not?

A:Indeed, we can supply free of charge sample if CZPT er agree to spend for the courier expense

6.Q:Do you have any certification?

A:Of course, we have CE certification and SGS certification report.

Speak to details:

Ms Lingel Pan

For any questions just feel totally free to speak to me. Numerous thanks for your kind attention to CZPT firm!

Polyphase motors can be either two-phase or a few-section motors. They operate like single-section induction motors, but the two one-phase and polyphase motors run on a rotating magnetic area. Their rotating magnetic fields are generated by two- or 3-section currents passing through two or far more sets of coils. The rotating magnetic discipline generates torque. Polyphase motors are utilised in applications that require large power, this sort of as the electrical power generate of compressors, hydraulic pumps, air conditioning compressors, and irrigation pumps.