Product Description

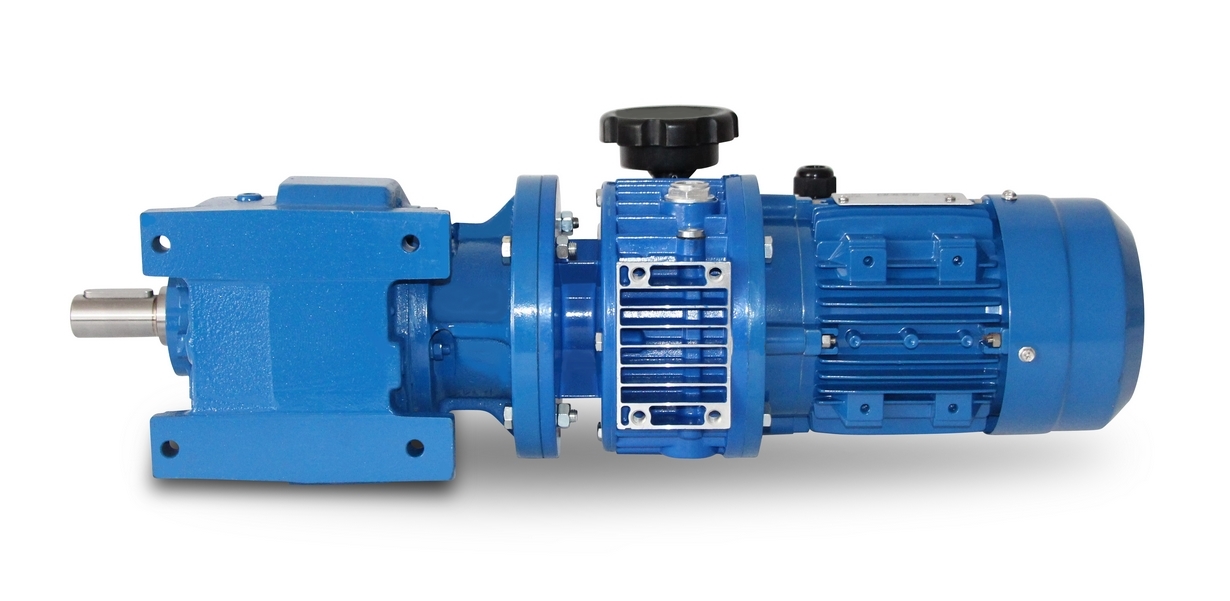

JWB-X SERIES SPEED VARIATOR

Characteristics

JWB-X With great reliability developed over 30 years of service, the JWB-X series is a valid alternative to electronic drives and is easy to use and maintain.

The JWB-X type in cast iron includes a wide range of models with flange, feet, with input shaft or in motorized version, are available in size number 04 and 05 ,input power is 1.1kw, 1.5kw,2.2kw,3kw,4kw.

The low-cost, light weight JWB-X B versions in aluminium,are available in size number 01, 02 and 03,04, input power is 0.18kw,0.25kw,0.37kw,0.55kw , 0.75kw,1.1kw and 1.5kw.

All type Certifications Available: ISO,CE,CQC,TUV,CCC certificate.

JWB-X type

- Sizes: 04,05

- Motor Power from 1.1 kW to 4 kW (Incldue 1.1kW,1.5kW,2.2kW,3kW,4kW)

- Cases in RAL 5571 blue cast iron

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors:

190-950r/min; 100-500r/min;80-400r/min;60-300r/min;40-200r/min;

30-150r/min;28-140r/min; 20-100r/min; 15-75r/min;4.7-23.5r/min;2-10r/min;

Output Torque value max 535Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control handwheel positionable on either side

- Slipping speed to max load at 5%

- Painted with blue epoxy-polyester powder

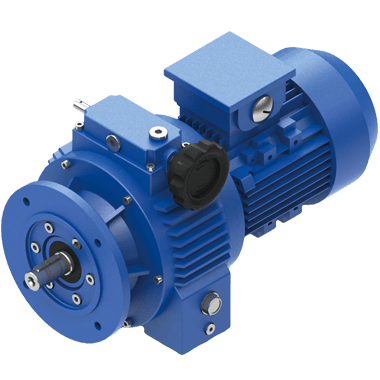

JWB-X B type

- Sizes: 01,02,03 and 04

- Motor Power up to 1.5 kW or less

(Incldue 0.18kW,0.25kW,0.37kW,0.55kW,0.75kW,1.1kW,1.5kW)

- Cases in die-cast aluminium alloy

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors:

190r/min-950r/min; 100r/min-500r/min;80r/min-400r/min;60r/min-300r/min;

40r/min-200r/min;28r/min-140r/min;25-125r/min; 18-90r/min; 15r/min-75r/min;

13-65r/min; 9-45r/min; 8-40r/min; 6.5-32.5r/min;4.7r/min-23.5r/min;2r/min-10r/min.

- Output Torque value max 795 Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control hand wheel positionable on either side

- Slipping speed to max load at 5%

- Painted with blue epoxy-polyester powder

| SPEED VARIATOR | Output Speed Range: | ||||

| SWB SERIES | 2rpm-950rpm | ||||

| Applicable Motor Power: | |||||

| 0.18kW-7.5kW | |||||

| Input Options 1: | |||||

| Type | Old Type | Output Torque | Output Shaft Dia. | With Inline AC Motor | |

| SWB01 | JWB01 | 2.6-1.6N.m | φ11 | Input Options 2: | |

| SWB02 | JWB02 | 258-1.8N.m | φ14, φ24, φ28, φ32 | With IEC Motor | |

| SWB03 | JWB03 | 426-4N.m | φ24, φ28, φ28, φ38 | Input Options 3: | |

| SWB04 | JWB04 | 795-8N.m | φ28, φ38, φ38, φ42 | With Input Shaft | |

| SWB05 | JWB05 | 535-16N.m | φ38, φ48, φ55 | Input Options 4: | |

| SWB06 | JWB06 | 1002-40N.m | φ42, φ55, φ70 | With Input Flange |

Starshine Drive

Certificate

Our Team

Quality Control

Packing

Delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Ceramic, Glass, Logistic |

|---|---|

| Certification: | CE, ISO, CQC,SGS,TUV |

| Structure: | Horizontal |

| Control System: | Manual Adjustment |

| Glass Washing Machine Type: | Transmission Parts |

| Glass Edging Machine Type: | Transmission Parts |

| Samples: |

US$ 300/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How does the size and power rating of variator motors impact their performance?

The size and power rating of variator motors have a significant impact on their performance. Here’s a detailed explanation of how these factors influence motor performance:

- Torque Output: The size and power rating of a variator motor directly affect its torque output. Generally, larger and higher-rated motors can deliver higher torque levels, allowing them to handle heavier or more demanding loads. A motor with higher torque capability can provide better acceleration, overcome resistance, and maintain stable operation under varying load conditions.

- Speed Range: The size and power rating of the motor also influence its speed range. Motors with higher power ratings can typically achieve a broader speed range, allowing for more flexibility in matching the motor’s speed to the application’s requirements. Smaller motors may have a more limited speed range, which can impact their suitability for certain applications that require a wide range of speeds.

- Overload Capacity: Larger and higher-rated variator motors generally have a higher overload capacity. They can handle temporary increases in load or momentary peak demands without experiencing significant performance degradation or overheating. This makes them suitable for applications with intermittent or cyclical loads, where occasional high torque requirements may arise.

- Efficiency: The size and power rating of a motor can impact its efficiency. In general, larger motors tend to have higher efficiencies, especially when operating near their rated capacity. Higher efficiency means less energy loss as heat and improved overall energy utilization. It’s important to select a motor with an appropriate power rating to ensure efficient operation while avoiding oversized motors that may operate at low efficiency levels.

- Physical Dimensions: The size of a variator motor directly affects its physical dimensions and weight. Larger motors typically have larger physical footprints and may be heavier. The physical dimensions of the motor can impact its installation requirements, space availability, and integration into the overall system design. It’s important to consider the available space and mounting requirements when selecting a motor of a suitable size.

- Heat Dissipation: The size and power rating of a motor influence its heat dissipation capabilities. Higher-rated motors generally generate more heat during operation, and larger motors have a larger surface area for heat dissipation. Adequate heat dissipation is crucial to prevent overheating and ensure the motor’s long-term reliability. It’s important to consider the motor’s cooling requirements, such as ventilation or cooling mechanisms, to maintain optimal operating temperatures.

- Cost: The size and power rating of a variator motor can impact its cost. Generally, larger and higher-rated motors tend to be more expensive than smaller ones due to the increased materials, manufacturing complexity, and performance capabilities. It’s important to balance the motor’s size, power rating, and associated cost with the specific requirements and budget of the application.

In summary, the size and power rating of variator motors significantly influence their performance in terms of torque output, speed range, overload capacity, efficiency, physical dimensions, heat dissipation, and cost. It’s crucial to carefully consider these factors when selecting a motor to ensure it meets the requirements of the application and delivers optimal performance and reliability.

Where can individuals find reputable suppliers or manufacturers of variator motors?

Individuals seeking reputable suppliers or manufacturers of variator motors have several options available. Here’s a detailed explanation:

1. Online Directories and Marketplaces: Online directories and marketplaces dedicated to industrial products and components can be a valuable resource. Platforms like Thomasnet, Alibaba, and GlobalSpec provide comprehensive listings of variator motor suppliers and manufacturers. These platforms often include detailed company profiles, product catalogs, and customer reviews, enabling individuals to assess the reputation and credibility of potential suppliers.

2. Trade Shows and Exhibitions: Attending trade shows and exhibitions related to the industrial or manufacturing sector can provide direct access to variator motor manufacturers and suppliers. These events offer opportunities to explore a wide range of products, interact with industry professionals, and establish contacts with reputable companies. Popular trade shows in the field include Hannover Messe, SPS IPC Drives, and Automation Fair.

3. Industry Associations and Organizations: Industry associations and organizations focused on electrical motors, automation, or specific industrial sectors often maintain directories or member listings that can help individuals find reputable variator motor suppliers. Examples include the International Electrotechnical Commission (IEC), National Electrical Manufacturers Association (NEMA), or sector-specific associations like the Robotics Industries Association (RIA) or the Packaging Machinery Manufacturers Institute (PMMI).

4. Consulting with Industry Professionals: Seeking advice and recommendations from industry professionals, such as engineers, consultants, or system integrators, can provide valuable insights on reputable variator motor suppliers. These professionals have experience with various suppliers and can offer guidance based on specific application requirements and industry knowledge.

5. Referrals and Word of Mouth: Networking within professional circles or reaching out to colleagues and peers in the industry can yield recommendations for reputable variator motor suppliers. Word of mouth referrals from trusted sources can provide firsthand information about the quality, reliability, and customer service of different suppliers.

6. Online Research and Reviews: Conducting online research and reading reviews about variator motor suppliers can help individuals gauge their reputation and assess customer satisfaction. Online forums, industry-specific websites, and social media platforms can provide insights and feedback from other customers who have worked with variator motor suppliers.

When evaluating variator motor suppliers or manufacturers, it’s important to consider factors such as their experience in the industry, product quality, certifications, technical support, warranty terms, and after-sales service. Requesting product samples, specifications, and references from potential suppliers can also help individuals make informed decisions.

By leveraging these resources and conducting thorough research, individuals can find reputable suppliers or manufacturers of variator motors that meet their specific requirements and ensure the quality and reliability of the products they purchase.

How does the efficiency of variator motors compare to other types of motors?

The efficiency of variator motors can vary depending on the specific design, application, and operating conditions. However, in general, variator motors can offer comparable or even higher efficiency compared to other types of motors. Here are some key points to consider:

- Variable Speed Operation: Variator motors excel in variable speed operations where the motor speed can be adjusted to match the load and process requirements. By running the motor at a speed that precisely meets the demand, variator motors can significantly reduce energy losses associated with running at fixed speeds. This level of control contributes to high overall system efficiency.

- Energy Savings through Speed Control: The ability to adjust the motor speed in variator motors allows for energy savings. By operating the motor at lower speeds when full speed is not required, variator motors can achieve energy efficiency gains. This is particularly relevant in applications with varying loads or processes that do not constantly require maximum speed.

- Improved Power Factor: Variator motors with adjustable speed control, such as those incorporating variable frequency drives (VFDs), can improve the power factor of the motor system. Power factor is a measure of how effectively electrical power is being used. By optimizing the motor speed and voltage, VFDs can improve the power factor, resulting in reduced reactive power consumption and improved energy efficiency.

- Motor Design and Technology: The efficiency of variator motors can also be influenced by the motor design and the use of advanced technologies. Manufacturers are continually improving motor designs, incorporating high-quality materials, precision manufacturing techniques, and efficient cooling systems to enhance motor efficiency. Additionally, advancements in motor technologies, such as the use of permanent magnet materials and improved motor control algorithms, contribute to higher overall efficiency.

- Comparison with Other Motor Types: When compared to traditional fixed-speed motors, variator motors generally offer higher efficiency due to their ability to adjust speed according to the load. In applications where variable speed control is required, variator motors can outperform fixed-speed motors in terms of energy savings, precise control, and overall system efficiency.

It’s important to note that the efficiency of variator motors can also depend on factors such as motor size, load characteristics, maintenance practices, and system design. Therefore, it’s advisable to consider specific motor specifications, consult with manufacturers, and conduct energy efficiency assessments to determine the most suitable motor type for a given application.

editor by CX 2024-04-13